Silicon-oxygen negative electrode material with mixed crystal phase as well as preparation method and application of silicon-oxygen negative electrode material

A technology of mixing crystal phases and negative electrode materials, which is applied in the field of materials, can solve the problems of insignificant performance advantages of material products, complex processes that cannot be mass-produced, and high equipment difficulty, so as to improve the depth of solid-phase reaction and the relative strength of SiO2 and silicate crystals. Effects of swelling reduction and high rate performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

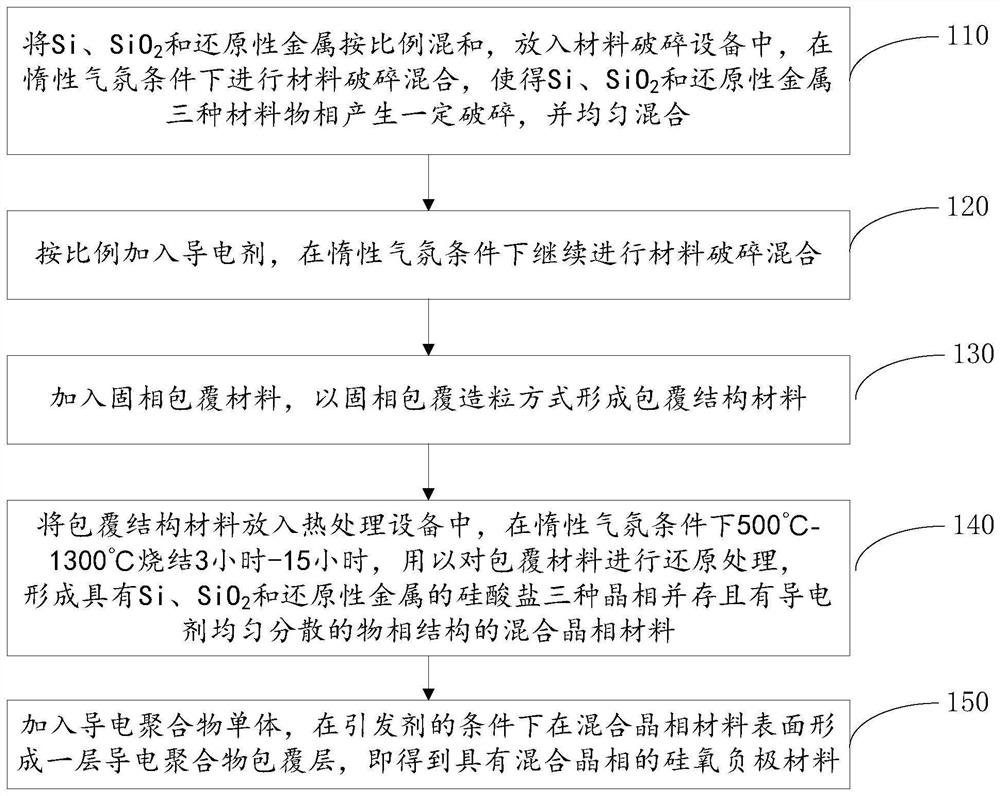

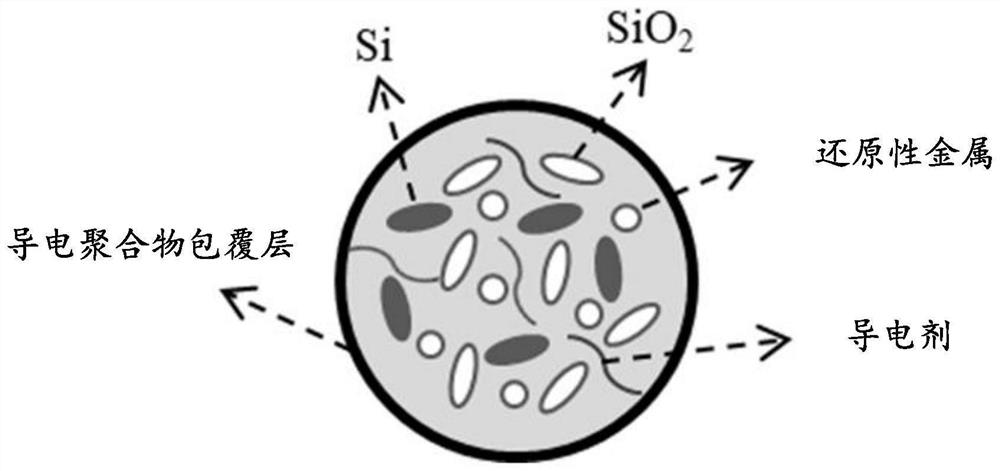

[0031] Embodiments of the present invention provide a silicon-oxygen negative electrode material with a mixed crystal phase and a preparation method thereof. The main steps of the preparation method of the material are as follows: figure 1 shown, including:

[0032] Step 110, Si, SiO 2 Mix with the reducing metal in proportion, put it into the material crushing equipment, and carry out material crushing and mixing under the condition of inert atmosphere, so that Si, SiO 2 The phases of the three materials with the reducing metal are broken to a certain extent and mixed uniformly;

[0033] Wherein, the reducing metal includes: one of lithium, sodium, magnesium, aluminum, potassium, and copper; the reducing metal accounts for 0.5%-15% of the total weight of the silicon-oxygen negative electrode material, preferably 1%-12%, More preferably 3%-9%.

[0034] Si is silicon powder, particle size D50=3μm-15μm; SiO 2 It is silica powder, particle size D50=1 μm-10 μm; the mass ratio ...

Embodiment 1

[0052] This example is used to prepare a silicon-oxygen negative electrode material with a mixed crystal phase.

[0053] Mix 50g D50=8μm Si powder and 100g D50=3μm SiO 2 The powder was put into a high-energy ball mill, and ball milled at 600rpm / min for 20 hours under an argon atmosphere;

[0054] Add 20g of 100 mesh Mg powder, and ball mill at 200rpm / min for 1 hour;

[0055] Add 2.5g CNTs, 100rpm / min ball mill for 15min;

[0056] Add 10g of asphalt into the high-energy ball mill tank, and ball mill at 200rpm / min for 15min;

[0057] After the materials are mixed evenly, put them into a corundum crucible, transfer them to a tube furnace, heat up to 900°C for sintering for 8 hours under an argon atmosphere, and take out the prepared powder samples;

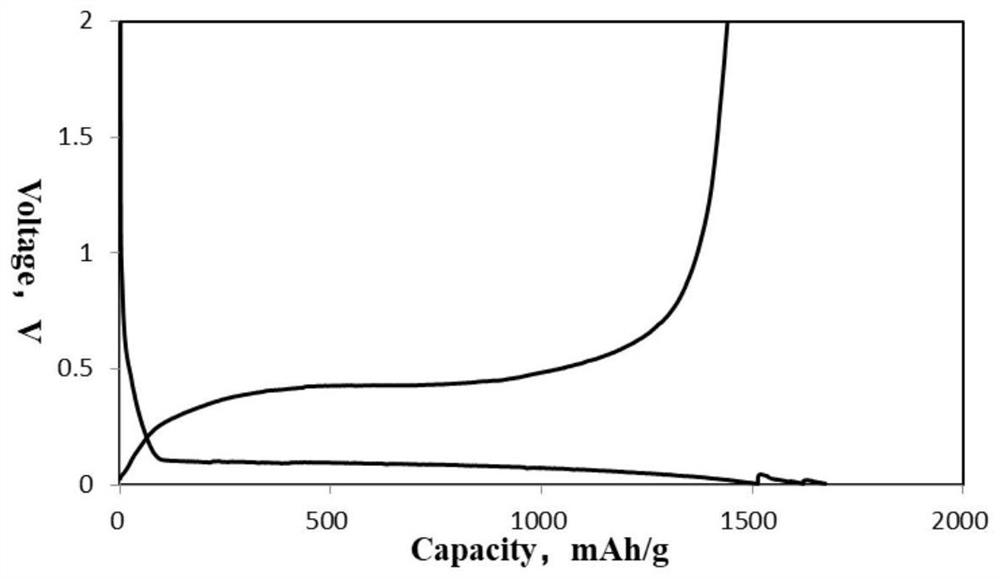

[0058] A layer of polypyrrole (ppy) conductive polymer accounting for 1.5 wt% of the total weight of the silicon-oxygen negative electrode material is coated by an in-situ polymerization method to obtain the final finished silicon...

Embodiment 2

[0062] This example is used to prepare a silicon-oxygen negative electrode material with a mixed crystal phase.

[0063] 65g D50=6μm Si powder and 162g D50=4μm SiO 2 The powder was put into a high-energy ball mill, and ball milled at 800 rpm / min for 15 hours under an argon atmosphere;

[0064] Add 20g of 100 mesh Cu powder, and ball mill at 150rpm / min for 1 hour;

[0065] Add 2.5g CNTs and 2.5g VGCF, 100rpm / min ball mill for 30 minutes;

[0066] Add 8g of phenolic resin into the high-energy ball mill tank, and ball mill at 200rpm / min for 15min;

[0067] After the materials are mixed evenly, put them into a corundum crucible, transfer them to a tube furnace, heat up to 800°C for sintering for 10 hours under an argon atmosphere, and take out the prepared powder samples;

[0068] A layer of polypyrrole (ppy) conductive polymer accounting for 2.0 wt% of the total weight of the silicon-oxygen negative electrode material is coated by an in-situ polymerization method to obtain the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com