Insulating material vacuum encapsulation device and method for traveling wave tube heater assembly

A technology of insulating materials and traveling wave tubes, which is applied in the field of insulating material vacuum sealing devices for thermal sub-assemblies of traveling wave tubes, can solve the problems of high time cost, low production efficiency, surface cracking, etc., and achieve improved density and surface hardness , Easy to design and manufacture, and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

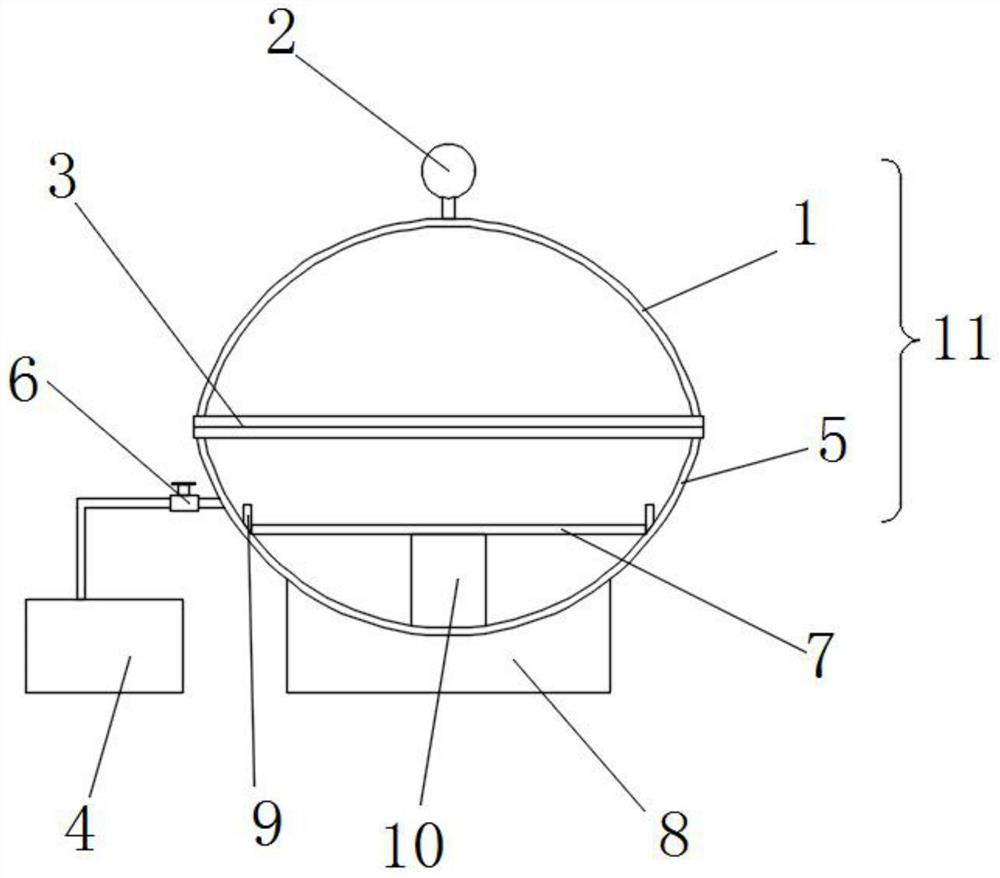

[0037] The densification treatment before sintering of heat-filled insulating materials is related to its strength, hardness, thermal shock resistance, insulation performance and other indicators after sintering. Therefore, in solving the problem of the defect of the thermal subassembly after sintering, the present invention proceeds from the following aspects: (1) A vacuum potting process is proposed: on the one hand, the residual gas inside the filler is discharged by using the difference in internal and external air pressure, and the solid-liquid mixed phase The filler will quickly fill the gap left after the residual gas is discharged, and on the other hand, the evaporation and dissipation of the organic solvent will be accelerated through the high-speed airflow to improve the efficiency of debinding; (2) Provide a set of vacuum perfusion equipment: it includes a set of self-made simple vacuum Equipment and a variety of special molds, the special mold can cover multiple tub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com