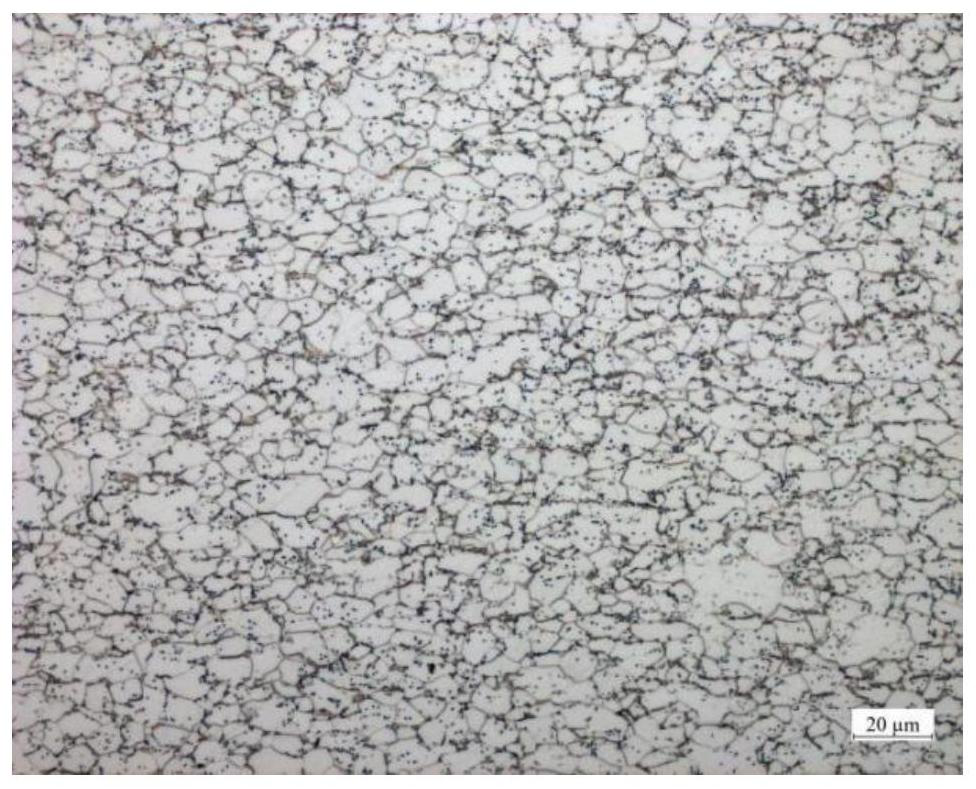

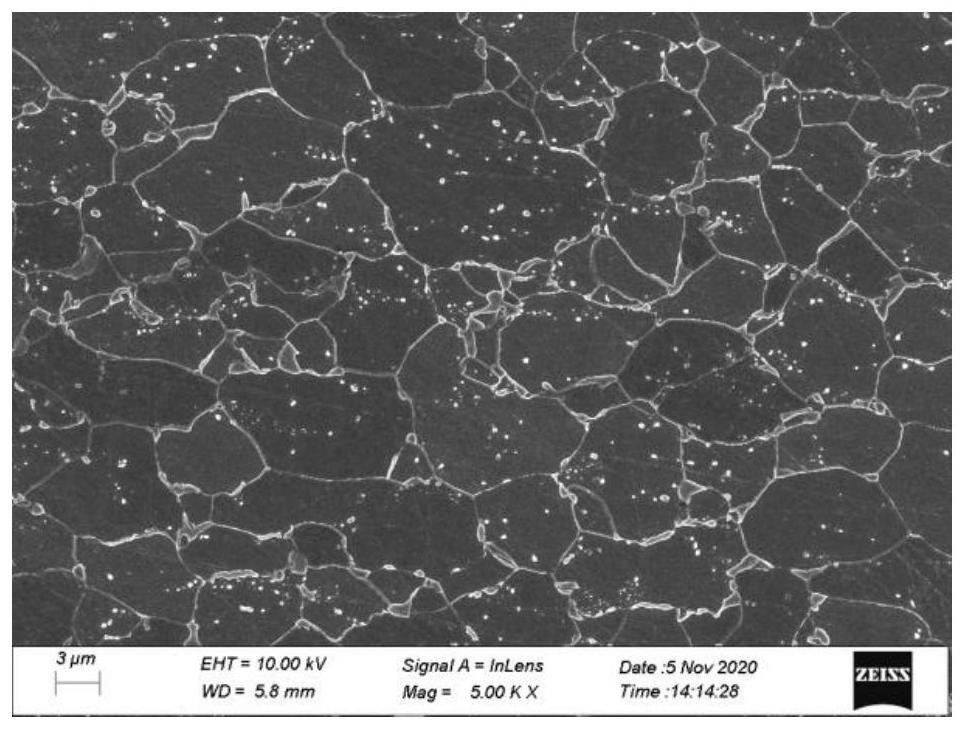

450 MPa-grade hot-dip galvanized dual-phase steel and production method thereof

A production method, 450mpa technology, applied in hot dip plating process, coating, metal material coating process and other directions, can solve the problems of poor forming effect, increase process cost, increase alloy cost, etc., achieve good market competitiveness, The effect of reducing production process costs and good surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Embodiment 1: This embodiment provides two groups of low-cost 450MPa hot-dip galvanized dual-phase steels, the chemical composition of which is shown in Table 1:

[0038] Table 1 Example 1 Cold-rolled dual-phase steel chemical composition (wt.%)

[0039] serial number C Si mn P S N als 1 0.055 0.42 1.70 0.010 0.002 0.0024 0.045 2 0.060 0.44 1.75 0.012 0.001 0.0036 0.042

[0040] The preparation method of the above-mentioned low-cost 450MPa grade hot-dip galvanized dual-phase steel, the specific process is as follows:

[0041] A, smelting process: through smelting process, prepare the duplex steel slab of chemical composition as shown in Table 1;

[0042] B. Hot rolling process: the slab is heated, dephosphorized, hot rolled and laminar cooled to obtain a hot rolled coil. The specific hot rolling process parameters are as shown in Table 2:

[0043] Table 2 Example 1 Cold-rolled dual-phase steel hot-rolled main process param...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com