Preparation method and application of temperature-resistant and salt-resistant six-arm star-shaped polyacrylamide

A polyacrylamide, temperature-resistant and salt-resistant technology, used in chemical instruments and methods, drilling compositions, etc., can solve the problems of unstable molecular chain structure, decreased viscosity and viscoelasticity, and easy entanglement of molecular chains. , to achieve good solubility, avoid curling, and high regional crosslink density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

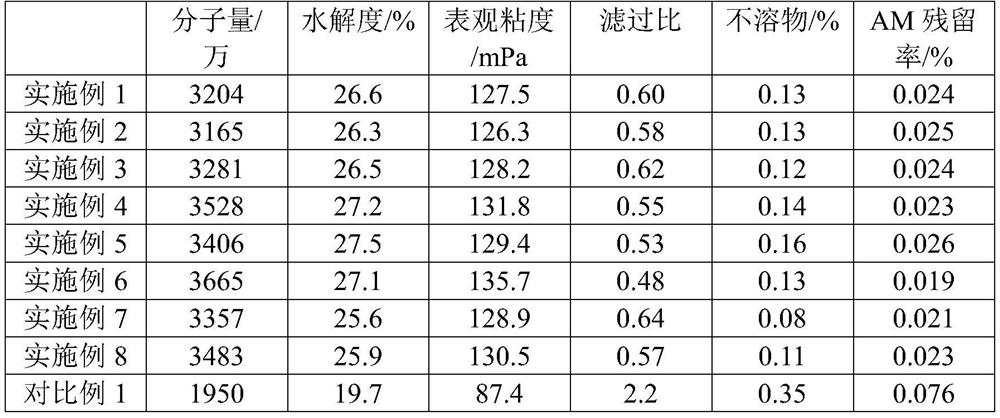

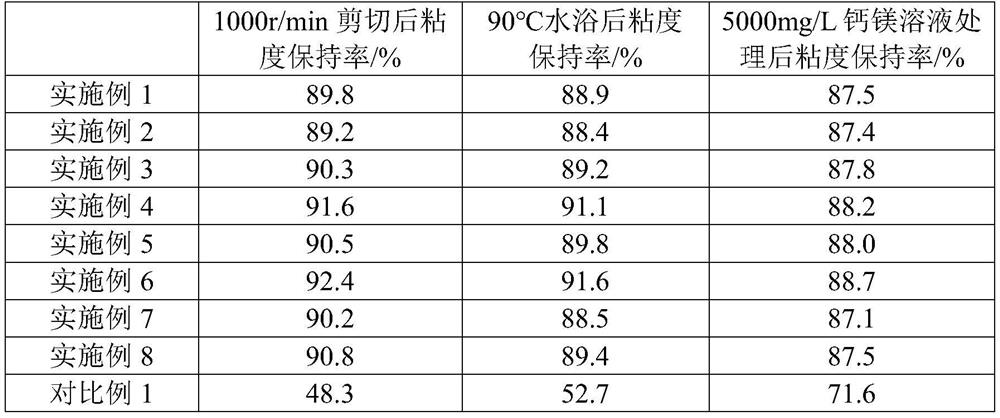

Examples

preparation example Construction

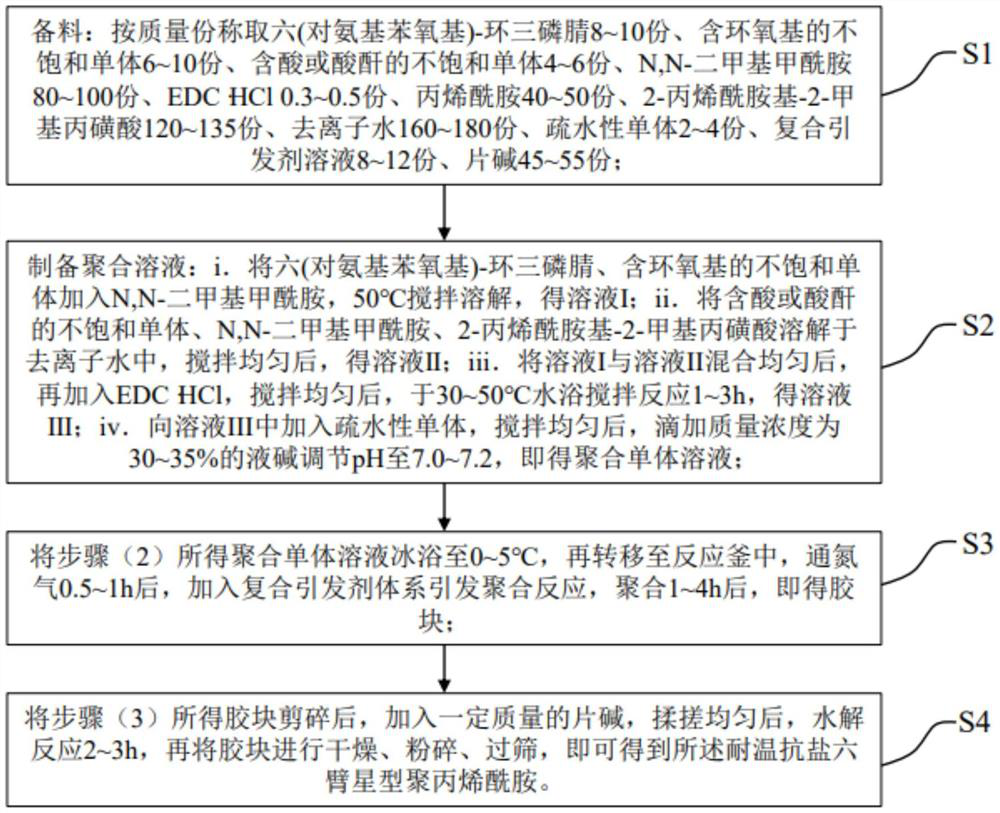

[0034] This example provides a method for preparing a temperature-resistant and salt-resistant six-arm star-shaped polyacrylamide. The six-arm star-shaped polyacrylamide uses hexa(p-aminophenoxy)-cyclotriphosphazene as a rigid structural core, and Ring-opening addition reaction with unsaturated monomers containing epoxy group, acylation reaction with unsaturated monomers containing acid or anhydride, and then with acrylamide, 2-acrylamido-2-methylpropanesulfonic acid , hydrophobic monomers are copolymerized, specifically comprising the following steps:

[0035] (1) Preparation of materials: Weigh 8 to 10 parts of hexa(p-aminophenoxy)-cyclotriphosphazene, 6 to 10 parts of unsaturated monomers containing epoxy groups, unsaturated mono 4-6 parts of N,N-dimethylformamide, 80-100 parts of N,N-dimethylformamide, 0.3-0.5 parts of EDC·HCl, 40-50 parts of acrylamide, 120 parts of 2-acrylamido-2-methylpropanesulfonic acid ~135 parts, 160~180 parts of deionized water, 2~4 parts of hydro...

Embodiment 1

[0047] (1) Material preparation: Weigh 8 g of hexa(p-aminophenoxy)-cyclotriphosphazene, 6 g of allyl glycidyl ether, 5 g of itaconic acid, 90 g of N,N-dimethylformamide, 0.5 g of EDC·HCl g, 45g of acrylamide, 130g of 2-acrylamido-2-methylpropanesulfonic acid, 165g of deionized water, 2.5g of hexadecyldimethylallyl ammonium chloride, 10g of compound initiator solution, caustic soda 50g; the composite is made up of the following components in mass percentage: (a) 0.1% potassium persulfate; (b) 0.1% sodium sulfite; (c) 0.15% azobisisobutyronitrile; (d) 0.1% N, N-dimethylaminoethyl methacrylate; (e) 0.1% ethylenediamine; (f) 0.4% isopropanol; (g) 0.5% urea; (h) deionized water to make up the remaining quantity;

[0048] (2) Preparation of polymerization solution:

[0049] i. Add hexa(p-aminophenoxy)-cyclotriphosphazene and allyl glycidyl ether into N,N-dimethylformamide, stir and dissolve at 50°C to obtain solution I;

[0050] ii. Dissolve itaconic acid, N,N-dimethylformamide, ...

Embodiment 2

[0056] Same as Example 1, except that 6g of allyl glycidyl ether is replaced by 6g of 4-vinylbenzyl glycidyl ether.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com