Preparation method of composite carrier

A technology of composite carrier and silica gel, which is applied in the field of preparation of composite carrier, can solve the problems of low content of magnesium chloride adsorbed on silica gel, low catalytic activity, complicated manufacturing method, etc., and achieve good fluidity, improved catalytic activity, and low manufacturing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

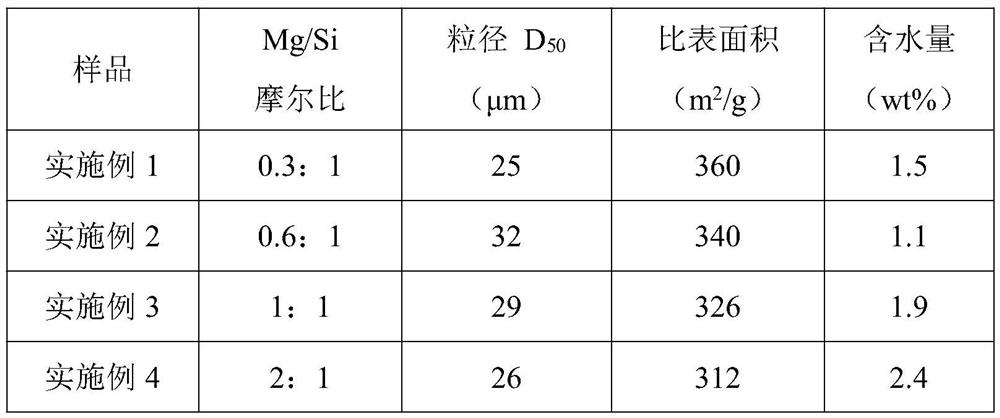

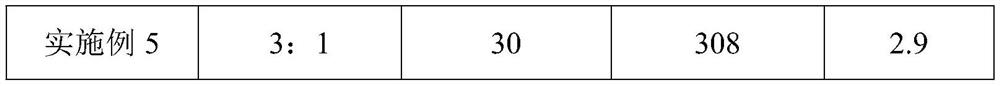

Examples

Embodiment 1

[0031] The method of preparing a silica gel composite carrier having a magnesium chloride content in this example is as follows:

[0032] 5.5 kg of sodium silicate was placed in the reactor, and 50 kg of deionized water was added, and the concentration of 0.0% sulfuric acid was added to the side, and after 2 hours, the aqueous sulfuric acid aqueous solution was adjusted to 2 ~ 3, aging reaction for 2 hours, was washed multiple times with deionized water, filtered until the sodium ion content in the reaction system was ≤0.1% by weight, and the plate frame filter was filtered to prepare a silica gel cake.

[0033] The silica gel cake was placed in a pulverket, and 2.7 kg of sixwater chloride powder and deionized water gamping were added. The slurry solid content was controlled at 15%, and the prepared slurry was used to apply a fine grinding pump to circulate 4 times, after measuring pump The centrifugal spray dryer is introduced for spray drying to obtain a water-containing composi...

Embodiment 2

[0036] The method of preparing a silica gel composite carrier having a magnesium chloride content in this example is as follows:

[0037] 5.5 kg of sodium silicate was placed in the reactor, and 50 kg of deionized water was added, and the concentration of 0.0% sulfuric acid was added to the side, and after 2 hours, the aqueous sulfuric acid aqueous solution was adjusted to 2 ~ 3, aging reaction for 2 hours, was washed multiple times with deionized water, filtered until the sodium ion content in the reaction system was ≤0.1% by weight, and the plate frame filter was filtered to prepare a silica gel cake.

[0038]The silica gel cake was put into beating kettle, 5.3kg of magnesium chloride hexahydrate powder and deionized water pulping, the slurry solids content is controlled to 15%, after application of the slurry prepared fine grinding polishing pump cycle 4 times, by a metering pump introducing a centrifugal spray drier was spray dried to obtain a composite aqueous carrier.

[003...

Embodiment 3

[0041] The method of preparing a silica gel composite carrier having a magnesium chloride content in this example is as follows:

[0042] 5.5 kg of sodium silicate was placed in the reactor, and 50 kg of deionized water was added, and the concentration of 0.0% sulfuric acid was added to the side, and after 2 hours, the aqueous sulfuric acid aqueous solution was adjusted to 2 ~ 3, aging reaction for 2 hours, was washed multiple times with deionized water, filtered until the sodium ion content in the reaction system was ≤0.1% by weight, and the plate frame filter was filtered to prepare a silica gel cake.

[0043] The silica gel cake was put into beating kettle, 9kg magnesium chloride hexahydrate powder and deionized water pulping, the slurry solids content is controlled to 15%, after application of the slurry prepared fine grinding polishing pump cycle 4 times, introduced by a metering pump a centrifugal spray drier was spray dried to obtain a composite aqueous carrier.

[0044] Ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com