Hydroxyapatite ceramic as well as preparation method and application thereof

A technology of hydroxyapatite and ceramics, applied in medical science, tissue regeneration, prosthesis, etc., can solve the problems of low compressive strength of materials, irregular micro-pore and hundred-micron pore structure, etc., and achieve high porosity and liquid Absorbency, simple process, low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

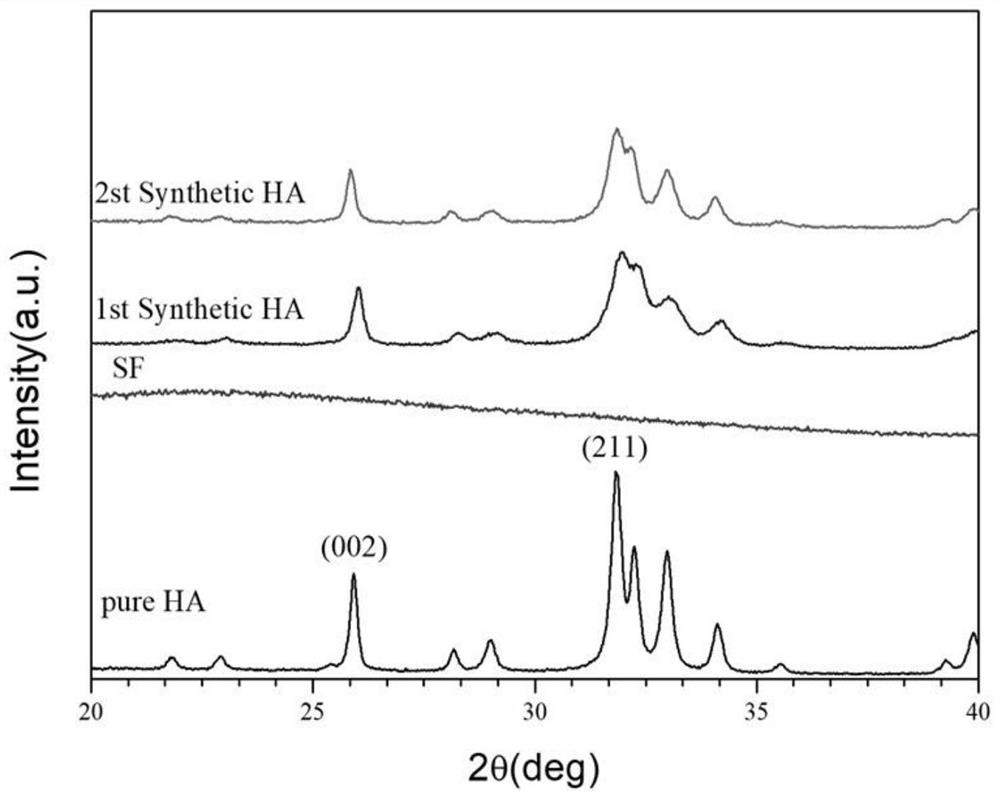

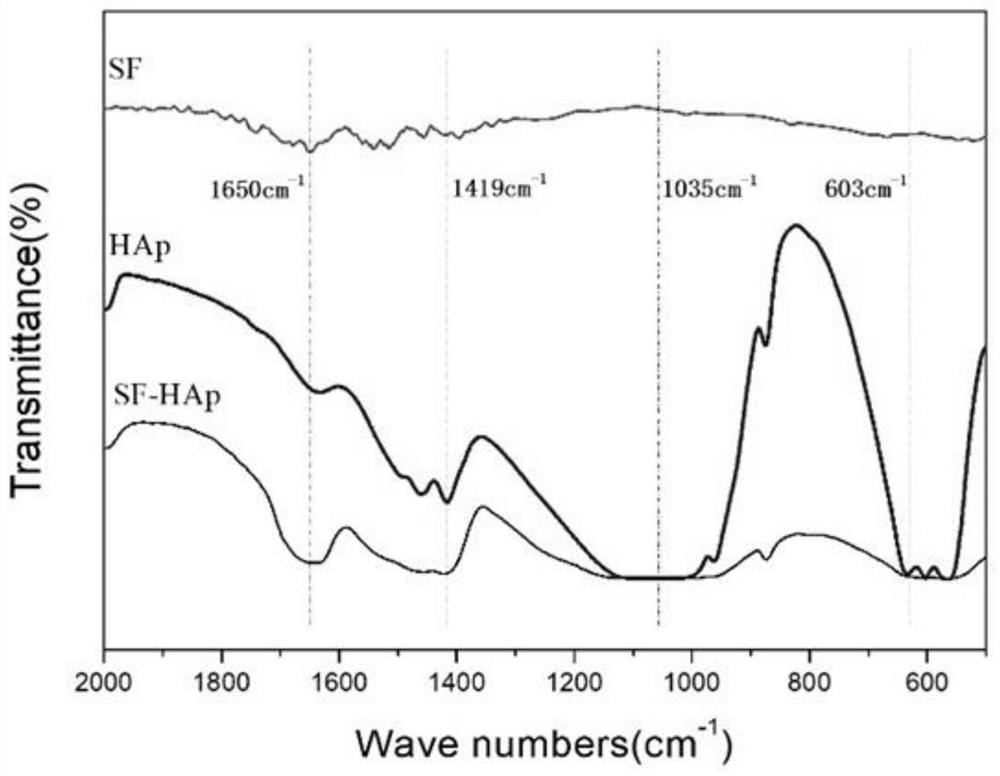

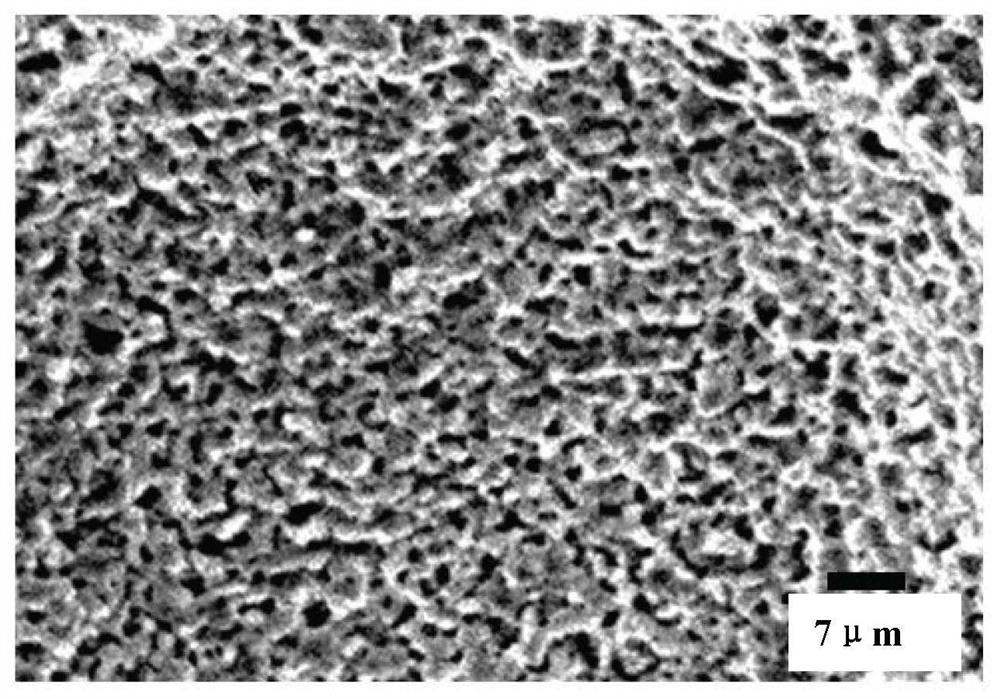

Method used

Image

Examples

Embodiment 1

[0034] The present embodiment Ca / P feed ratio is 1.67.

[0035] (1) Dissolve 27.84mL concentrated phosphoric acid in 1L pure water, dissolve 30g silk fibroin in 330mL water, and stir vigorously while mixing the two to obtain a silk fibroin-phosphate solution; dissolve 49.95g calcium hydroxide in 4L water to obtain a calcium hydroxide suspension.

[0036] (2) Divide the silk fibroin-phosphoric acid solution into 8 equal volumes, add it to the calcium hydroxide suspension in 8 times, and adjust the pH to 10-11 after each addition, and react at 70°C for 30 minutes; finally Add silk fibroin-phosphoric acid solution once to react for 1h.

[0037] (3) Remove the supernatant after incubating the reacted solution overnight, and centrifuge at a speed of 5000r / min to obtain a solid substance; the solid substance is washed 3 times with pure water, and the supernatant is removed; finally, it is dried in an oven at 40°C Dry the solid material until it is completely irregular in size.

...

Embodiment 2

[0044] According to the preparation method of Example 1, under the condition that other parameters of Example 1 remain unchanged, the static pressure is changed, and the influence of the static pressure on the compressive strength, elastic modulus, and liquid absorption of the final product is studied. The results are shown in Table 1:

[0045] The final product properties obtained under the different static pressure conditions of table 1

[0046] Ca / P feed ratio static pressure Compressive strength Elastic Modulus liquid absorbency 1.67 1MPa 0.8MPa 11.43MPa 81.20% 1.67 3 MPa 1.2 MPa 17.14MPa 75.32% 1.67 5MPa 2.0MPa 25.1MPa 75.13% 1.67 10MPa 2.5MPa 35.71 MPa 70.11% 1.67 20MPa 17.7MPa 252.86MPa 65.11%

[0047] The results show that as the static pressure increases, the compressive strength and elastic modulus of the final product increase, and the liquid absorbency decreases. When the static pressure i...

Embodiment 3

[0049] In this embodiment, the Ca / P feed ratio is controlled to be 1.50, that is, the control step (1) is: dissolve 6.96mL of concentrated phosphoric acid in 0.25L of pure water, dissolve 7.5g of silk fibroin in 82.5mL of water, and mix the two together. Stir vigorously to obtain a silk fibroin-phosphate solution; dissolve 11.318g of calcium hydroxide in 1L of water to obtain a calcium hydroxide suspension. All the other steps and parameters are the same as in Example 1. Change the static pressure to study the effect of static pressure on the compressive strength, elastic modulus and liquid absorption of the final product. The results are shown in Table 2:

[0050] The final product properties obtained under the different static pressure conditions of table 2

[0051] Ca / P feed ratio static pressure Compressive strength Elastic Modulus liquid absorbency 1.50 5MPa 2.6MPa 37.14 MPa 60.32% 1.50 10MPa 7.2MPa 102.86 MPa 65.22% 1.50 20...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com