Preparation method of polyvinyl alcohol resin high in alcoholysis degree

A technology of polyvinyl alcohol resin and high degree of alcoholysis, which is applied in the field of production of polyvinyl alcohol resin, can solve problems such as toxicity, products not meeting the requirements of medical grade, and affecting the physical, chemical and mechanical properties of polymer emulsions. The effect of increasing production and increasing conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

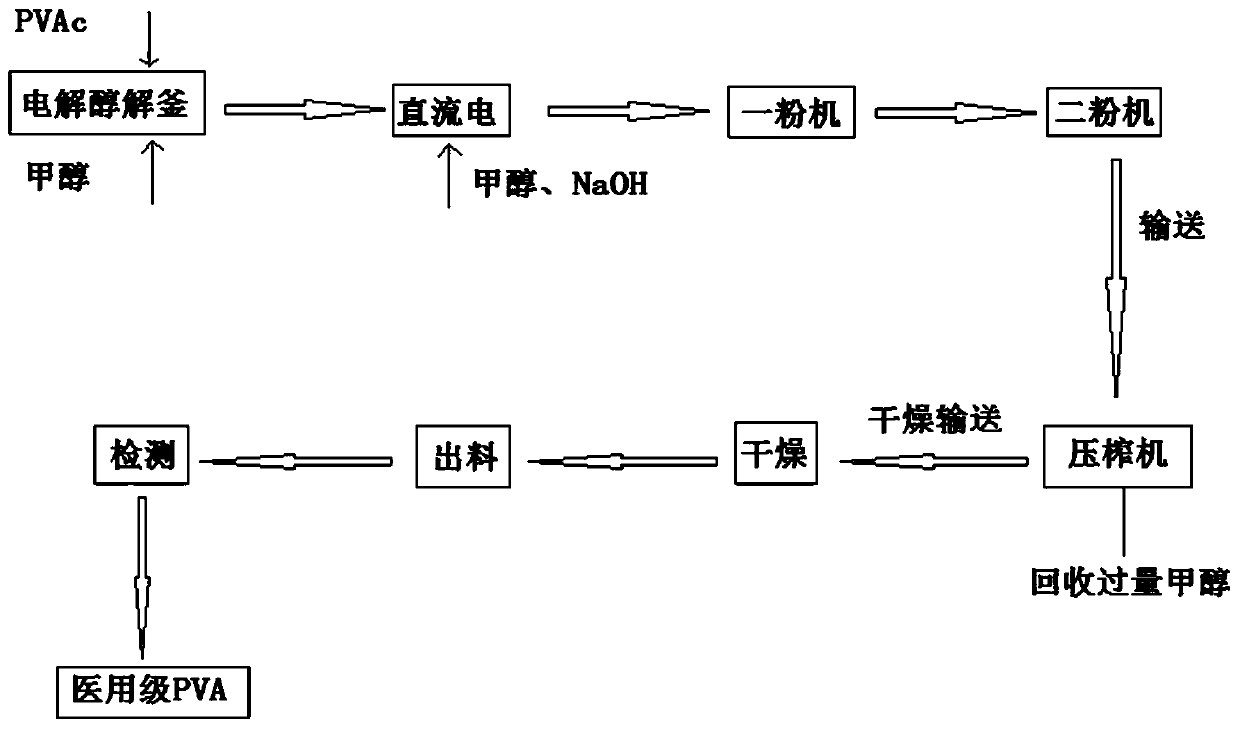

[0030] Such as figure 1 Shown, a kind of preparation method of high degree of alcoholysis polyvinyl alcohol resin comprises the steps:

[0031] The first step: preparation of PVAc / methanol solution.

[0032] Add methanol solution into the electrolytic alcoholysis kettle, slowly add PVAc particles under stirring, heat to 55°C to fully dissolve, and obtain PVAc-methanol solution; the weight ratio of PVAc / methanol solution is 20-22 / 78-80 , as a preference, the weight ratio of PVAc / methanol solution is 22 / 78.

[0033] The second step: the preparation of alkali-methanol solution,

[0034] The base was dissolved in methanol solution. The type of base is not limited, as long as it can provide hydroxide ions, it can be used in the present invention. The base is NaOH, and the weight ratio of NaOH-methanol solution to PVAc is 12%.

[0035] The third step: put polymethylsiloxane into the electrolytic alcoholysis ax with PVAc / methanol solution, and then pass in direct current under th...

Embodiment 1

[0054] first step:

[0055] Add 60 kg of methanol solution into the electrolytic alcoholysis kettle, slowly add 240 kg of PVAc particles under stirring, and heat to 55°C to fully dissolve the PVAc particles to obtain a PVAc-methanol solution; the ratio of PVAc / methanol solution is 20 / 80 .

[0056] Step two:

[0057] Another container was used to weigh 28.8 kg of NaOH solid and dissolve it in 160 kg of methanol solution.

[0058] The third step: put 2.16 kilograms of polymethylsiloxane into the electrolytic reactor of the first step, and then put the product obtained in the second step into the electrolytic reactor at 200 rpm. Under the condition of keeping the temperature at 45-48°C, direct current is supplied, and the direct current voltage is 20 volts. The positive and negative poles are located on both sides of the electrolytic alcoholysis kettle. Stir for 33 minutes at a speed of 200 revolutions per minute.

[0059] Step 4: Stop stirring, heat to the range of 58-65°C, ...

Embodiment 2

[0062] first step:

[0063] Add 66 kg of methanol solution into the electrolytic alcoholysis kettle, slowly add 234 kg of PVAc particles under stirring, and heat to 55°C to fully dissolve the PVAc particles to obtain a PVAc-methanol solution; the ratio of PVAc / methanol solution is 22 / 78 .

[0064] Step two:

[0065] Another container was used to weigh 28.08 kg of NaOH solid and dissolve it in 153 kg of methanol solution.

[0066] The third step: put 2.106 kg of polymethylsiloxane into the first step electrolytic reaction kettle, and then put the product obtained in the second step into the electrolytic reaction kettle at 200 rpm. Under the condition of keeping the temperature at 45-48°C, direct current is supplied, and the direct current voltage is 20 volts. The positive and negative poles are located on both sides of the electrolytic alcoholysis kettle. Stir for 33 minutes at a speed of 200 revolutions per minute.

[0067] Step 4: Stop stirring, heat to the range of 58-65...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volatile matter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com