PET material injection molding device and using method thereof

A technology of injection molding and injection molding tubes, which is applied in the field of PET material injection molding devices, can solve the problems of quality reduction and injection molding efficiency reduction, and achieve the effect of increasing temperature, reducing the absolute magnetic effect, and comprehensive contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

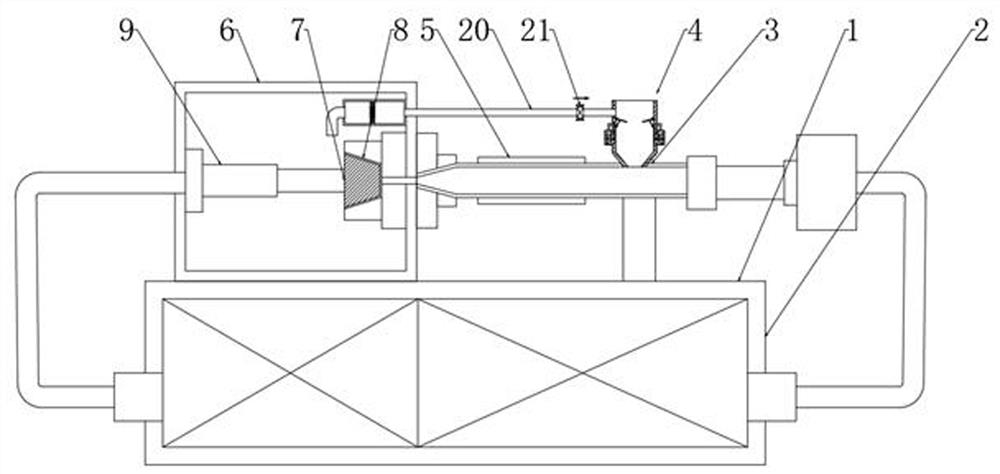

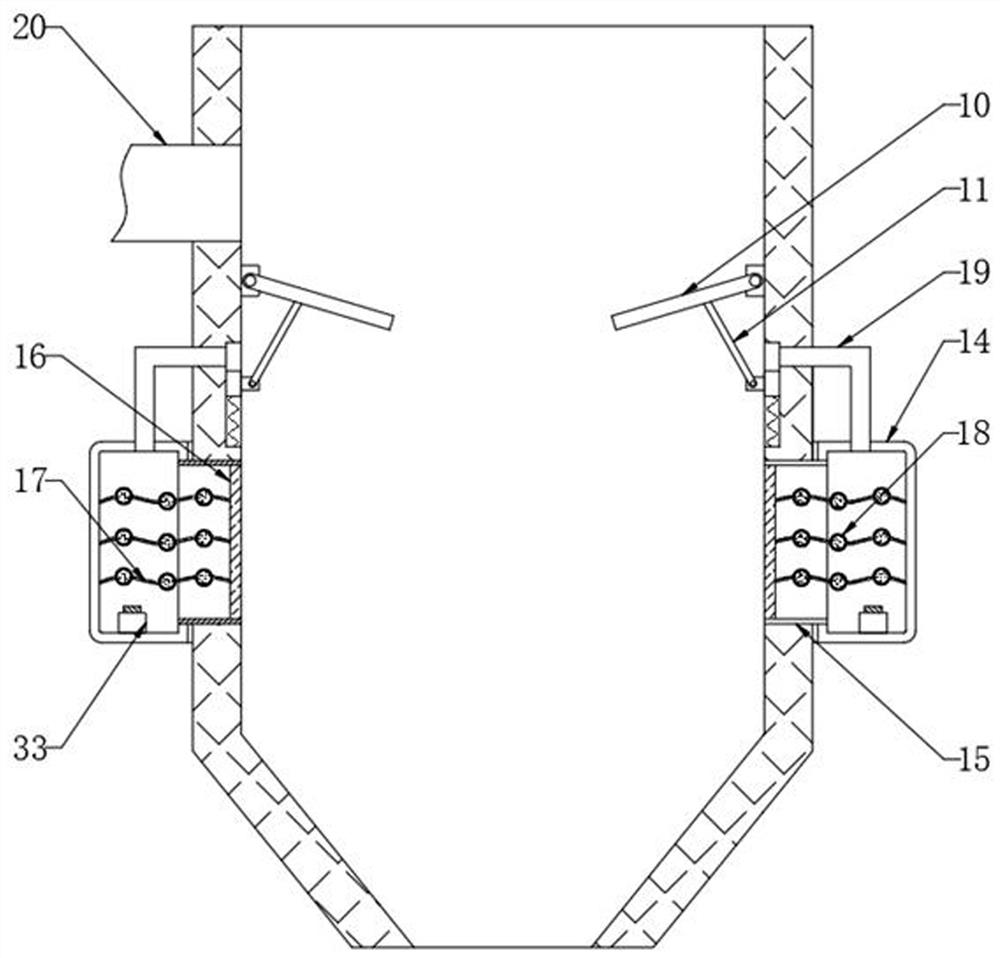

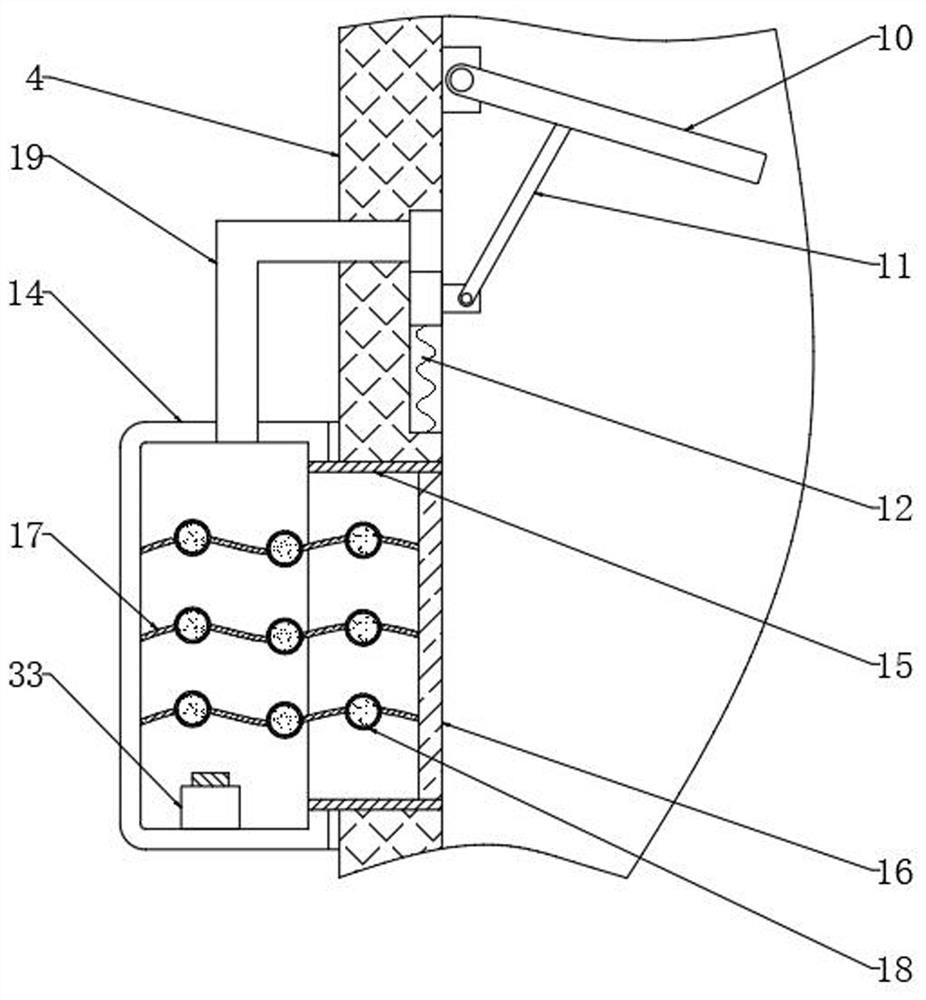

[0036] see figure 1 , a PET material injection molding device, including a working platform 1, an injection mechanism 2 is installed between the inner side walls of the working platform 1, an injection tube 3 is fixedly connected to the upper end of the working platform 1, and the output end of the injection mechanism 2 is connected to the injection tube 3 The right end of the injection pipe 3 is fixedly connected, the upper end of the injection pipe 3 is fixedly connected with the feeding hopper body 4, the feeding hopper body 4 communicates with the inside of the injection pipe 3, the outer end of the injection pipe 3 is equipped with a heating mechanism 5, and the upper end of the working platform 1 is fixedly connected There is an injection molding frame 6, the inner side wall of the injection molding frame 6 is fixedly connected with a fixed mold 8, and a material guide hole is dug in the injection molding frame 6, and the left end of the injection molding tube 3 runs thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com