Preparation method of all-inorganic semiconductor quantum dot laser

An inorganic semiconductor, quantum dot technology, applied in semiconductor lasers, semiconductor laser structure details, lasers, etc., can solve problems such as bottleneck laser device stability, achieve high-performance spatially oriented laser emission, avoid further damage, and excellent solvent dispersion sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A kind of concrete steps of the preparation method of semiconductor quantum dots modified by inorganic ligands:

[0029] (1) Preparation of CdSe / CdS core-shell quantum dots: first, use CdO and oleic acid to prepare cadmium oleate as a Cd precursor, and add Se precursor to the prepared cadmium oleate to prepare CdSe nuclear quantum dots; then, the The above-mentioned purified CdSe quantum dots, 10 mL oleylamine and 30 g octadecane were added into a three-necked flask. Under the protection of argon, the reaction temperature was raised to 240 °C, and the Cd precursor and the S precursor were alternately injected using the continuous ion layer adsorption and reaction method. CdSe / CdS core-shell quantum dots with a shell thickness of 11 CdS monolayers were obtained by controlling the injection amount of the precursor, which were dispersed in toluene after centrifugal purification.

[0030] (2) Preparation of all-inorganic CdSe / CdS@ZnO quantum dots

[0031] Pretreatment of ...

PUM

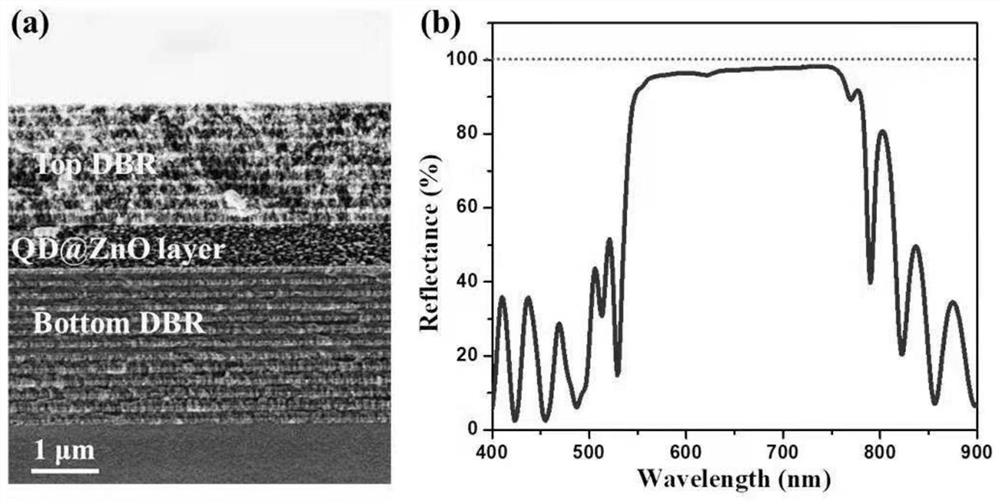

| Property | Measurement | Unit |

|---|---|---|

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com