Growth method of beta-Ga2O3 film

A growth method, -ga2o3 technology, applied in the field of semiconductor thin film growth, can solve the problems of high surface roughness and multiple dislocations in thin films, and achieve the effect of reducing surface roughness, realizing transition, and enhancing two-dimensional growth.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

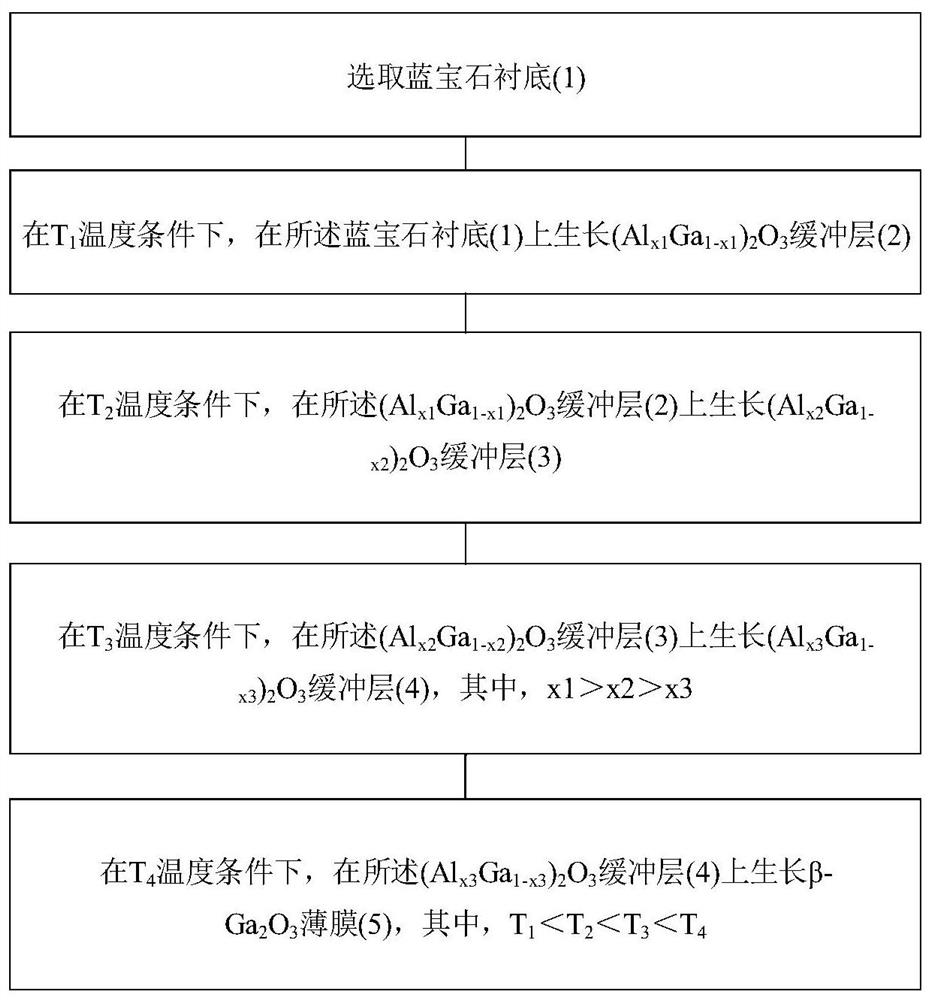

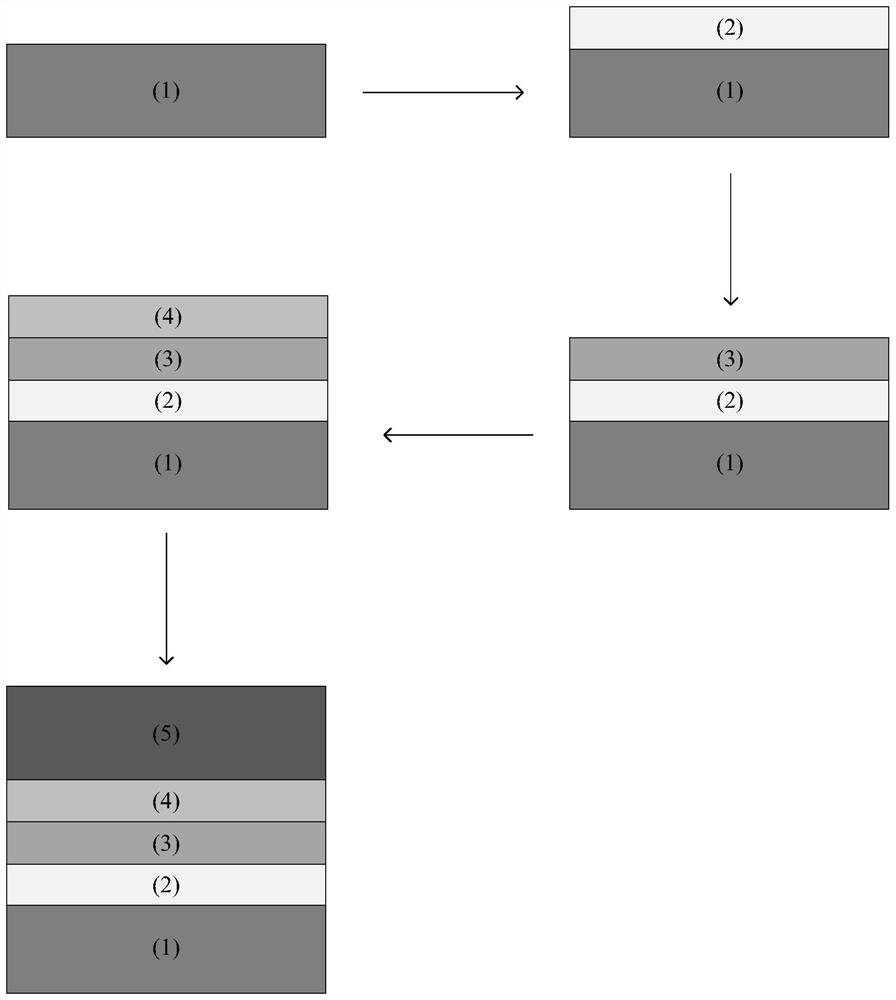

[0036] See figure 1 , figure 2 , figure 1 One β-Ga provided by the embodiment of the present invention 2 O 3 A flow chart of the growth method of the film, figure 2 One β-Ga provided by the embodiment of the present invention 2 O 3 A process diagram of the preparation of the growth method of the film. The present invention provides a β-Ga 2 O 3 The growth method of the film, the growth method includes the following steps:

[0037] Step 1, select the sapphire substrate 1.

[0038] Specifically, the sapphire substrate is placed in an HF acid solution for soaking, then the sapphire substrate is soaked with alcohol and acetone, then rinse the sapphire substrate after the flowing deionized water, and finally blows with high purity nitrogen. The sapphire substrate after drying.

[0039] Preferably, the HF acid solution consists of a solution having a HF acid content of 30%.

[0040] Preferably, the sapphire substrate 1 includes a chemically mechanical polished C-Plane sapphire substrate...

Embodiment 2

[0068] The present embodiment provides a production of 3 min (Al) based on the above embodiment 1-x GA x ) 2 O 3 Buffer β-Ga 2 O 3 Growth method of film.

[0069] Step 1, the sapphire substrate was submerged in a solution of the HF acid content of 30%, and then washed with alcohol and acetone, then rinsed with a flow of deionized water, and finally was blown with high purity nitrogen.

[0070] Step 2, epitaxial growth 3 min (Al 0.8 GA 0.2 ) 2 O 3 buffer layer.

[0071] Specifically, the cleaning sapphire substrate is placed in a low pressure MOCVD reaction chamber, high purity O 2 For the O source, the temperature of the reaction chamber is 500 ° C in TEGA and TEAL, respectively, and the growth pressure is 40 torr, TEGA flow is 40 sccm, and TEAL flow is 40sccm, O 2 The flow rate is 2100 sccm, and the growth of 3 min is extends on sapphire substrate (Al 0.8 GA 0.2 ) 2 O 3 buffer layer.

[0072] Step 3 and improve the growth temperature.

[0073] Specifically, maintaining other grow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com