Method for preparing porous ceramic by in-situ curing molding of water-based slurry containing aluminum ash

A technology of in-situ solidification and porous ceramics, which is applied in the direction of ceramic products, ceramic material production, clay products, etc., can solve the problems of high cost, inconspicuous pore-forming effect, low addition of aluminum nitride, etc., to achieve low cost and realize The effect of resource disposal and low volume density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

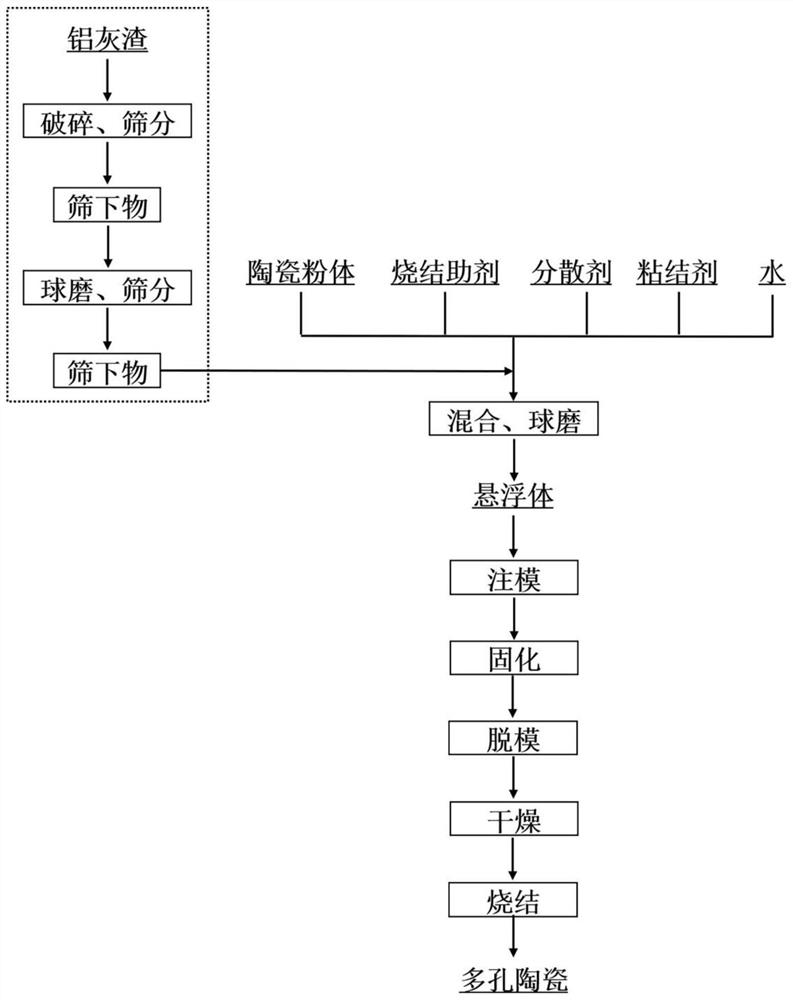

Method used

Image

Examples

Embodiment 1

[0052] 1) The aluminum ash slag was crushed by an extrusion crushing device for 10 minutes, and the crushed material was sieved through a 30-mesh sieve, and the weight of the undersize accounted for 90% of the total weight of the crushed material.

[0053] 2) The crushed and sieved materials were dry-milled in a ball mill for 72 hours, and the aluminum ash slag after ball milling was sieved through a 300-mesh sieve to remove difficult-to-grind materials, and the weight of the undersize accounted for 98% of the total weight of the ball-milled materials.

[0054] The raw material solid is secondary aluminum ash slag with a mass content of 100%, and dispersant ammonium citrate accounting for 0.05% of the total mass of the raw material solid, binder polyvinyl alcohol accounting for 0.01% of the total mass of the raw material solid, and 0.01% of the total mass of the raw material solid are added. 1% sintering aid SiO 2 Afterwards, it was mixed with water and ball milled for 10 minu...

Embodiment 2

[0058] 1) The aluminum ash slag was crushed by extrusion crushing device for 100 minutes, and the crushed material was sieved through a sieve with an aperture of 30 mesh, and the weight of the undersize accounted for 98% of the total weight of the crushed material.

[0059] 2) The crushed and sieved materials were wet-milled with alcohol in a ball mill for 36 hours, and the milled aluminum ash slag was sieved through a 300-mesh sieve to remove difficult-to-grind materials, and the weight of the undersize accounted for 99% of the total weight of the ball-milled materials.

[0060] The raw material solid is a mixture of aluminum slag and alumina ceramic powder, wherein the mass content of aluminum slag is 15%, and the balance is alumina; and dispersant ammonium polyacrylate, accounting for 1% of the total mass of raw material solid, is added. The binder sodium carboxymethyl cellulose of 8% of the total solid mass of the raw material, and the sintering aid CaO accounting for 0.01%...

Embodiment 3

[0064] 1) The aluminum ash slag was crushed for 60 minutes by an extrusion crushing device, and the crushed material was screened through a 30-mesh sieve, and the weight of the under-sieve accounted for 95% of the total weight of the crushed material.

[0065] 2) The crushed and sieved materials were wet-milled in a ball mill with alcohol for 30 minutes, and the aluminum ash slag after ball milling was sieved through a 300-mesh sieve to remove difficult-to-grind materials, and the weight of the undersize accounted for 98% of the total weight of the ball-milled materials.

[0066] The raw material solid is a mixture of aluminum ash slag and quartz ceramic powder, wherein the mass content of aluminum ash slag is 50%, and the balance is quartz powder; adding 0.5% of the dispersant tetramethylammonium hydroxide, Binder silica sol accounting for 10% of the total mass of raw material solids, sintering aid H accounting for 10% of the total mass of raw material solids 3 BO 3 Afterwar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com