Preparation method of multilayer functional ceramic component

A technology of functional ceramics and components, which is applied in the preparation of multilayer functional ceramic components and in the field of multilayer functional ceramic components, can solve the problems of metal guide post fracture failure, thermal expansion coefficient difference, interlayer cracking and penetration, etc., to reduce the metal circuit Structural fracture, reducing the probability of warping and deformation, and improving the effect of thermal expansion matching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A method for preparing a multilayer functional ceramic part of the present embodiment comprises the following steps:

[0041] S1. Prepare ceramic slurry, tape-cast the ceramic slurry to obtain a ceramic green sheet;

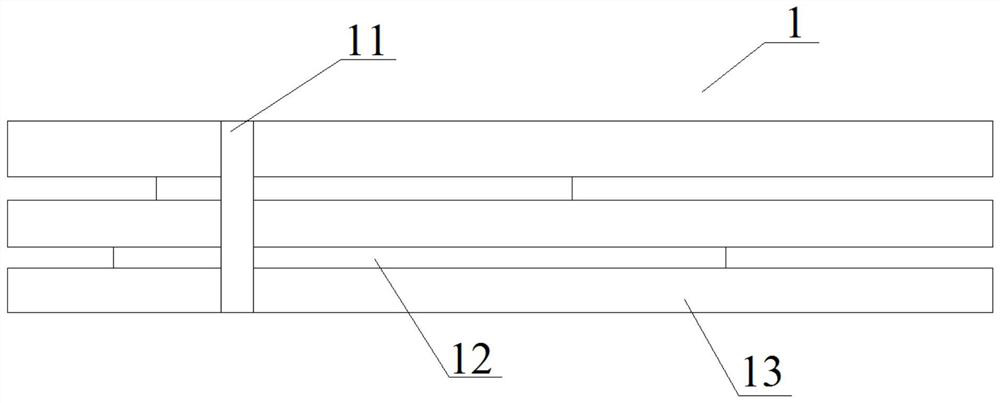

[0042] S2. After cutting the ceramic green sheet, punching holes at predetermined positions to obtain a plurality of ceramic sheets with through holes;

[0043] S3, preparing a gel injection molding slurry comprising an organic additive capable of initiating gelation;

[0044] S4, stacking a plurality of ceramic sheets with through holes;

[0045] S5. Arrange the metal circuit structure in the interlayers and through holes of the laminated ceramic sheets or in the through holes of the laminated ceramic sheets, and inject the gel injection molding slurry that matches the metal circuit structure. After the gel is cured, the obtained Multilayer functional ceramic component body;

[0046] S6. Laminating the green body of the multilayer functional ceramic co...

Embodiment 2

[0051] A method for preparing a multilayer functional ceramic part of the present embodiment comprises the following steps:

[0052] S1. Prepare ceramic slurry, tape-cast the ceramic slurry to obtain a ceramic green sheet;

[0053] S2. After cutting the ceramic green sheet, punching holes at predetermined positions to obtain a plurality of ceramic sheets with through holes;

[0054] S3, preparing a gel injection molding ceramic slurry comprising an organic additive that can cause gelation;

[0055] S4, stacking a plurality of ceramic sheets with through holes;

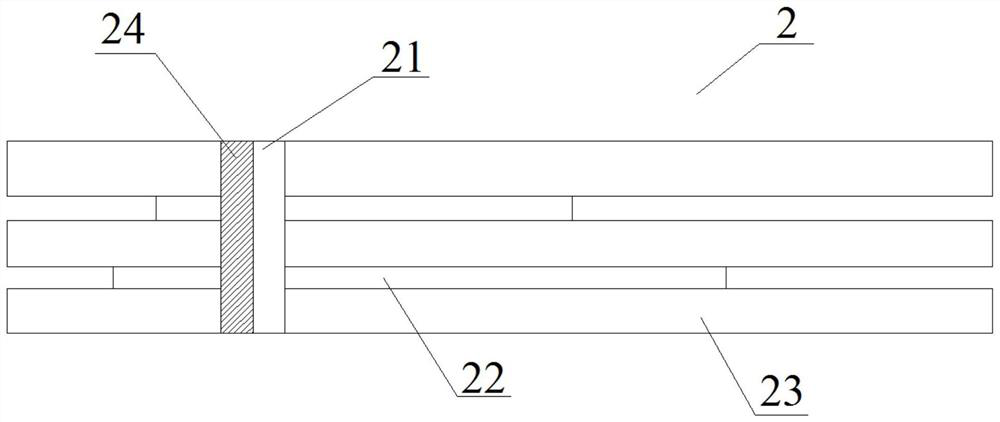

[0056]S5. Arranging a metal circuit structure in the interlayers and through holes of the laminated ceramic sheets, and injecting a gel injection molding ceramic slurry that matches the metal circuit structure, and obtaining a multilayer functional ceramic component green body after the gel is solidified; , the metal circuit structure includes a metal guide post arranged in a through hole and a metal circuit arranged...

Embodiment 3

[0071] A method for preparing a multilayer functional ceramic part of the present embodiment comprises the following steps:

[0072] S1. Prepare ceramic slurry, tape-cast the ceramic slurry to obtain a ceramic green sheet;

[0073] S2. After cutting the ceramic green sheet, punching holes at predetermined positions to obtain a plurality of ceramic sheets with through holes;

[0074] S3, preparing a gel injection molding ceramic slurry comprising an organic additive that can cause gelation;

[0075] S4, stacking a plurality of ceramic sheets with through holes;

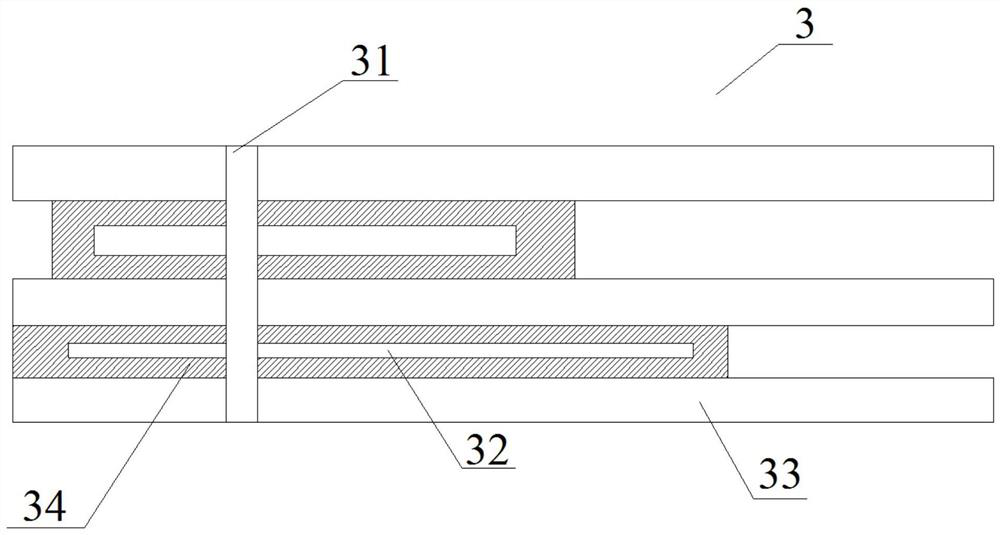

[0076] S5. Arranging a metal circuit structure in the interlayers and through holes of the laminated ceramic sheets, and injecting a gel injection molding ceramic slurry that matches the metal circuit structure, and obtaining a multilayer functional ceramic component green body after the gel is solidified; , the metal circuit structure includes metal guide posts arranged in through holes and metal circuits arranged b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com