Waterproof structure of roof parapet wall and construction method of waterproof structure

A technology for waterproof structures and parapets, which is applied to roofs, roof coverings, and roofs using flexible materials, etc., can solve the problems of reduced waterproof performance of parapet waterproof structures, and achieve convenient and simple structure, easy recycling, and enhanced adhesion degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

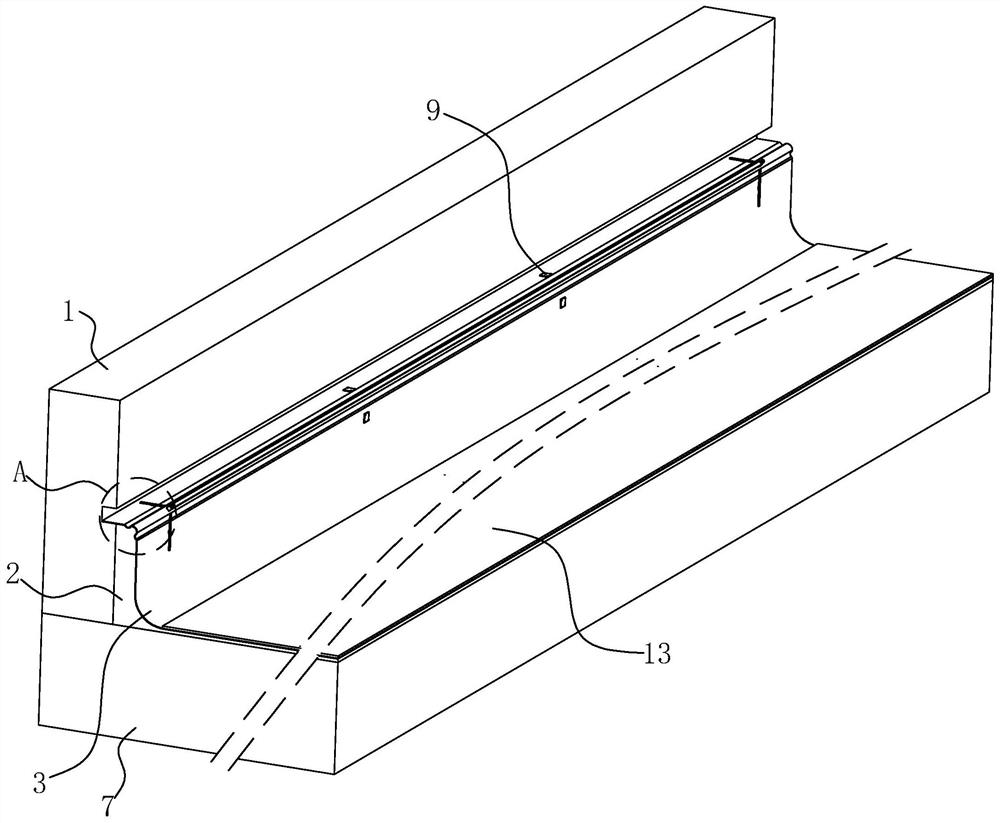

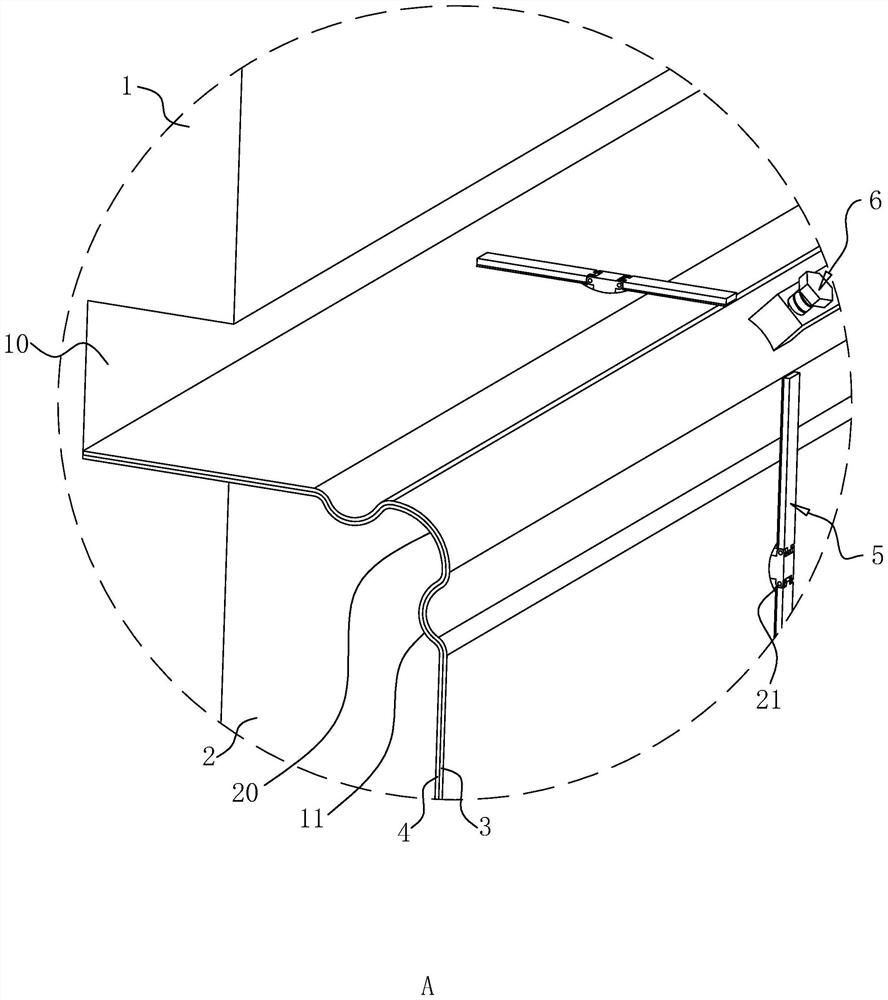

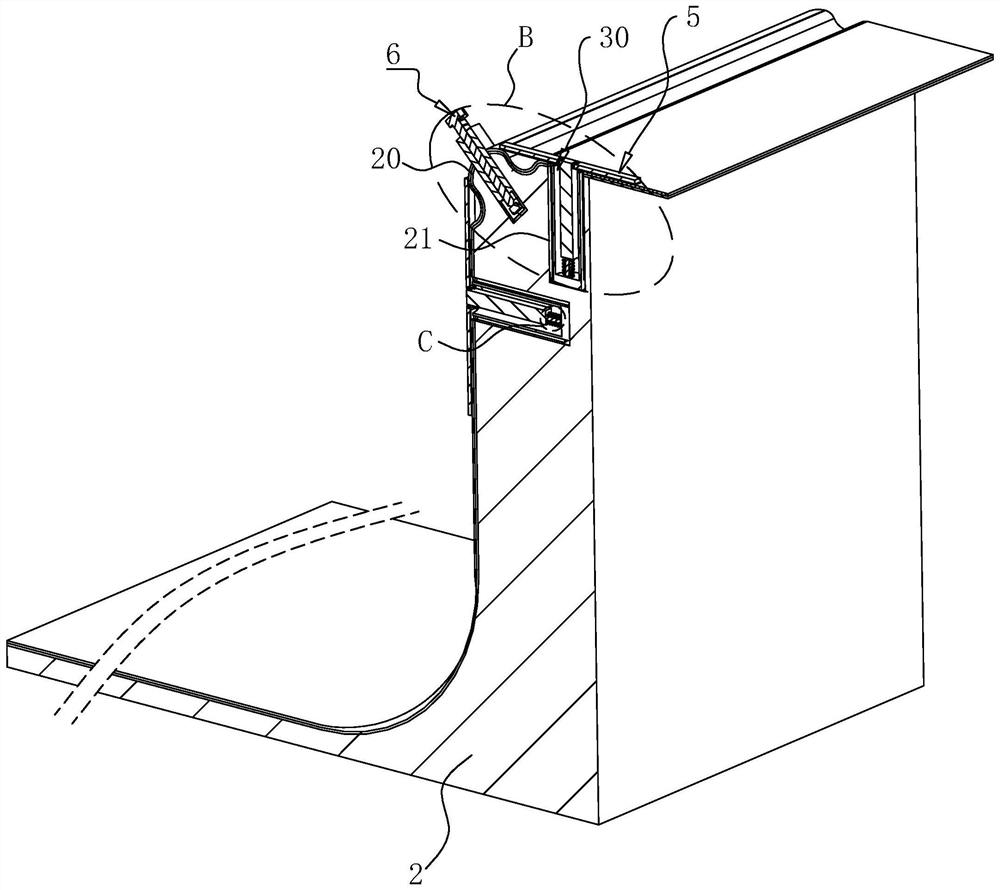

[0048] The following is attached Figure 1-9 The application is described in further detail.

[0049] The embodiment of the application discloses a waterproof structure of a roof parapet. refer to figure 1 and figure 2 The waterproof structure of the roof parapet includes a parapet body 1, a mortar leveling layer 2 coated on the roof 7 used to match the parapet body 1, an adhesive layer 4 coated on the mortar leveling layer 2, and a paving The waterproof coiled material 3 attached to the adhesive layer 4, the mortar leveling layer 2 is poured at the corner of the roof 7 and the parapet body 1, and the mortar leveling layer 2 extends to the side wall of the parapet body 1, and the mortar leveling layer 2. An inwardly recessed arc corner is provided at the vertical joint between the parapet body 1 and the roof 7, so as to reduce the degree of bending of the waterproof membrane 3 when it is pasted to the arc corner.

[0050] refer to figure 1 and figure 2 The parapet body...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com