A kind of potassium aluminosilicate nanogel precursor additive and its application in low calcium system geopolymer

A technology of nano-gel and potassium aluminosilicate, applied in cement production, etc., can solve problems such as hindering the promotion of the construction field, uneven hydration process, and affecting workability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

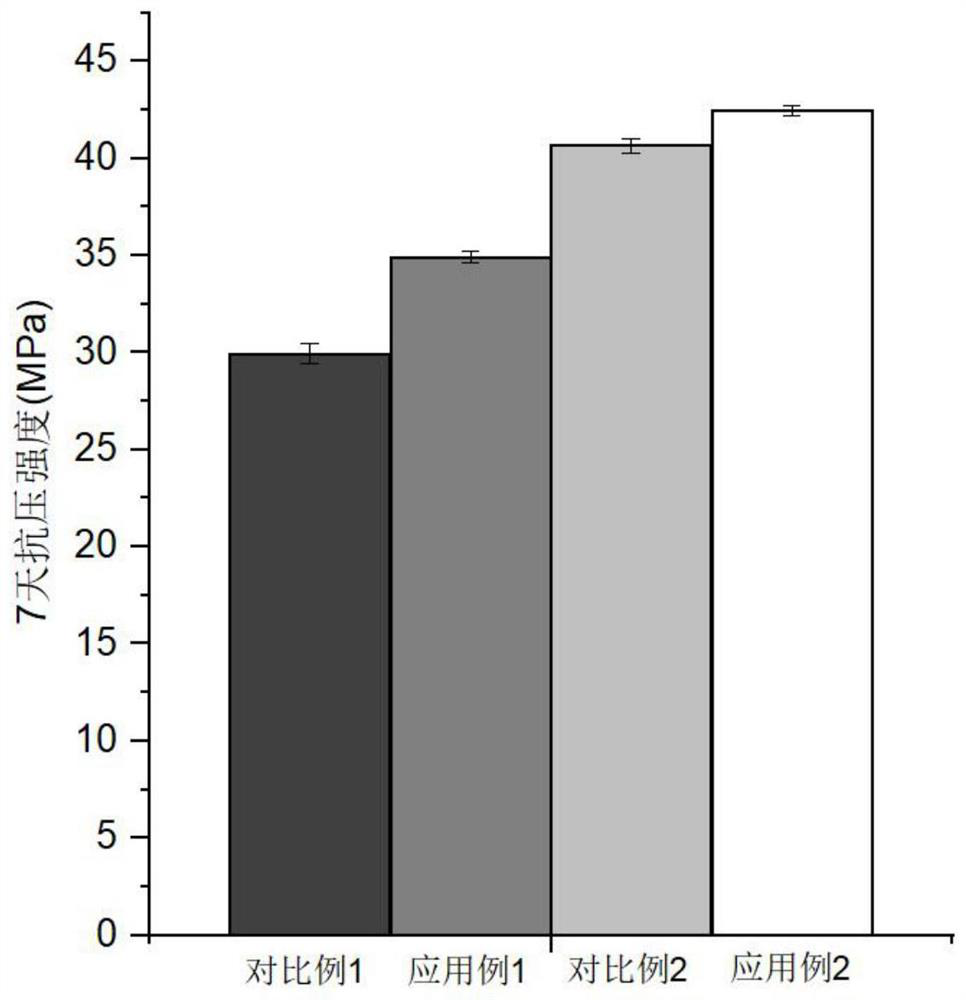

Examples

preparation example Construction

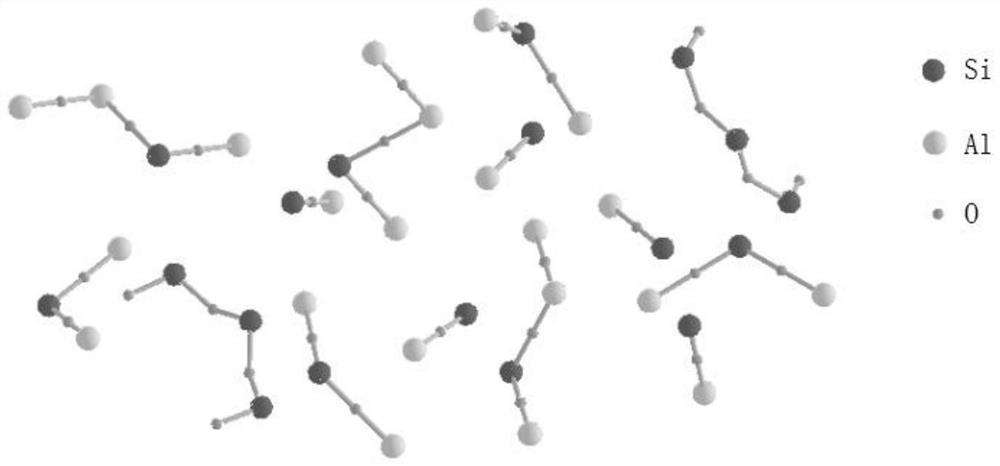

[0019] In the present invention, the preparation method of the potassium aluminosilicate nanogel precursor additive preferably includes the following steps:

[0020] The potassium hydroxide, nano-silica, nano-alumina and water are mixed to carry out a hydrothermal synthesis reaction to obtain the potassium aluminosilicate nano-gel precursor admixture.

[0021] In the present invention, unless otherwise specified, all raw material components are commercially available commodities well known to those skilled in the art.

[0022] In the present invention, the mass ratio of the potassium hydroxide, nano-silica, nano-alumina and water is preferably (4-15): (1.5-4): (0.75-2): (30-100), more Preferably (5-12): (2-3.5): (0.8-1.5): (40-80), most preferably (8-10): (2.5-3): (1-1.2): (50- 80). In the present invention, the water is preferably deionized water.

[0023] In the present invention, the temperature of the mixing is preferably 70-100°C, more preferably 75-95°C, and most pref...

Embodiment 1

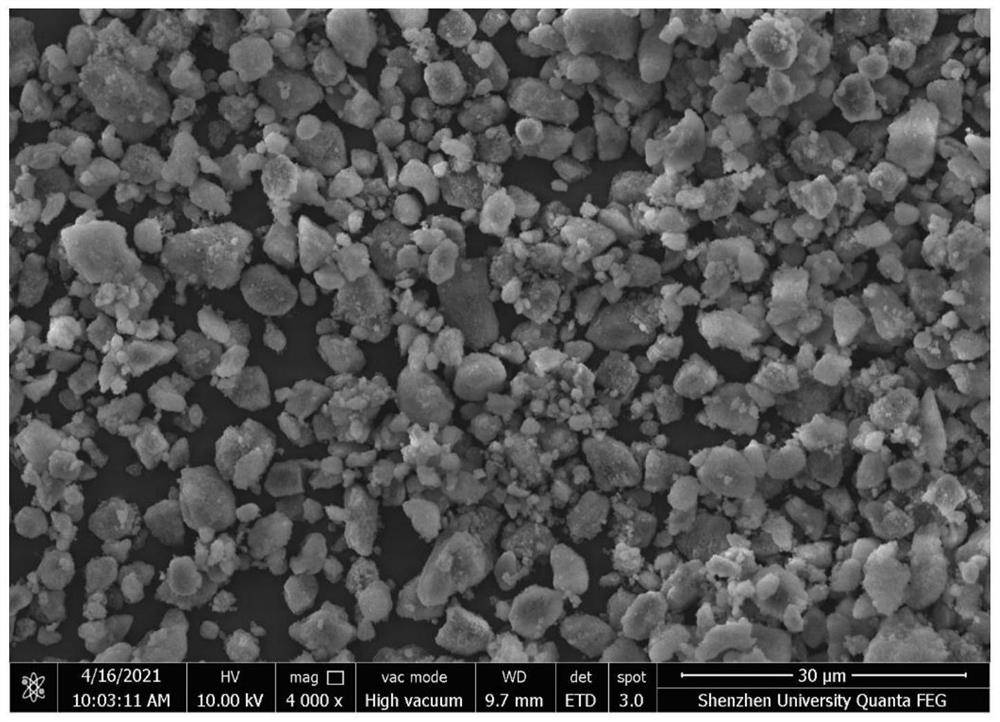

[0031] Add 300 parts of deionized water and 30 parts by mass of KOH to the Teflon reaction tank, put the Teflon tank into a water bath with a stirring speed of 200r / min and 95°C, and add it after the temperature rises to 95°C. 16 parts by mass of nano-SiO with a particle size of 50 to 100 nm 2Stir for 2min, add 14 parts by mass of nano-Al with a particle size of 50-100nm 2 O 3 After stirring for 2 minutes, take out the polytetrafluoroethylene tank and seal it with plastic wrap and adhesive tape, then continue to stir in the water bath for 1 hour, turn off the stirring knob, and let it stand at 95 °C for a constant temperature hydrothermal synthesis reaction for 4 hours. Centrifuge at a speed of 4000 r / min for 4 min, pour off the liquid components, add deionized water, stir and mix, continue to centrifuge at a speed of 4000 r / min for 4 min, and repeat centrifugal washing 3 times to obtain potassium aluminosilicate nanogel precursor. agent;

[0032] In the potassium aluminosi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com