Tensile machine for testing ductility of plastic rod

A ductility and tension machine technology, applied in the field of performance testing devices, can solve problems such as integrity damage, damage, and breakage, and achieve the effect of improving accuracy, ensuring integrity, and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

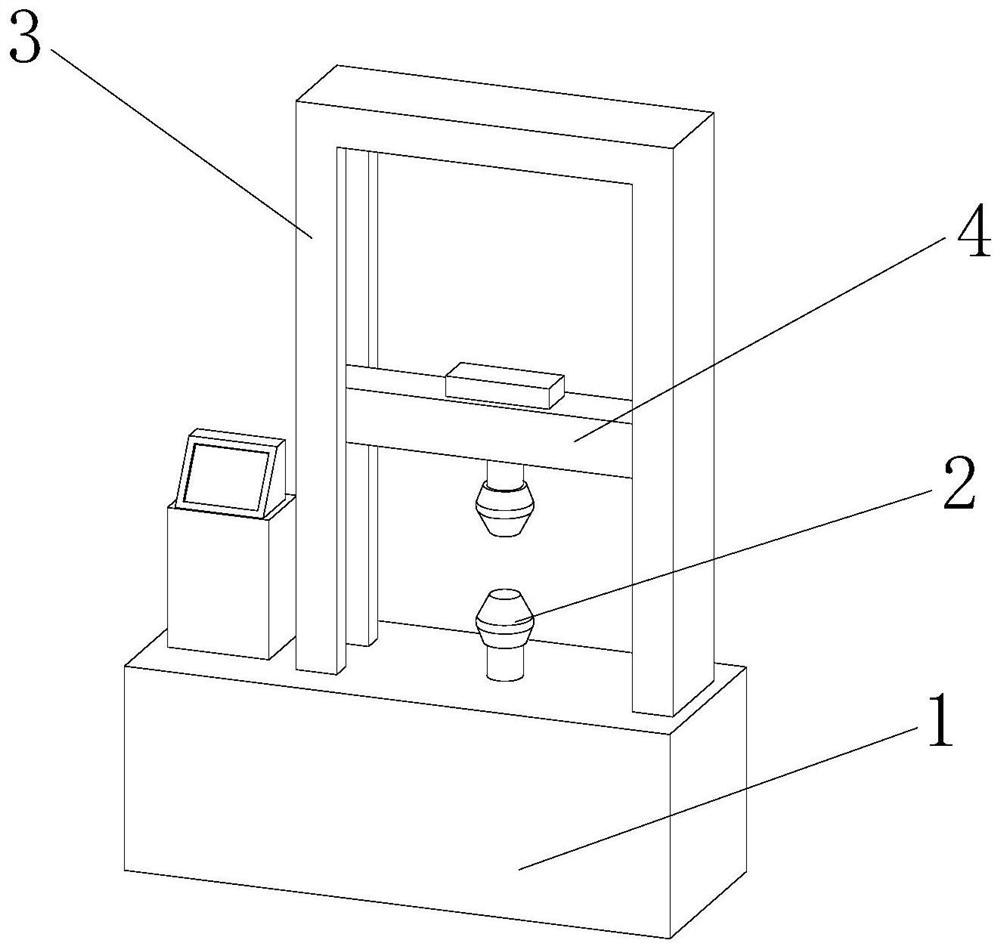

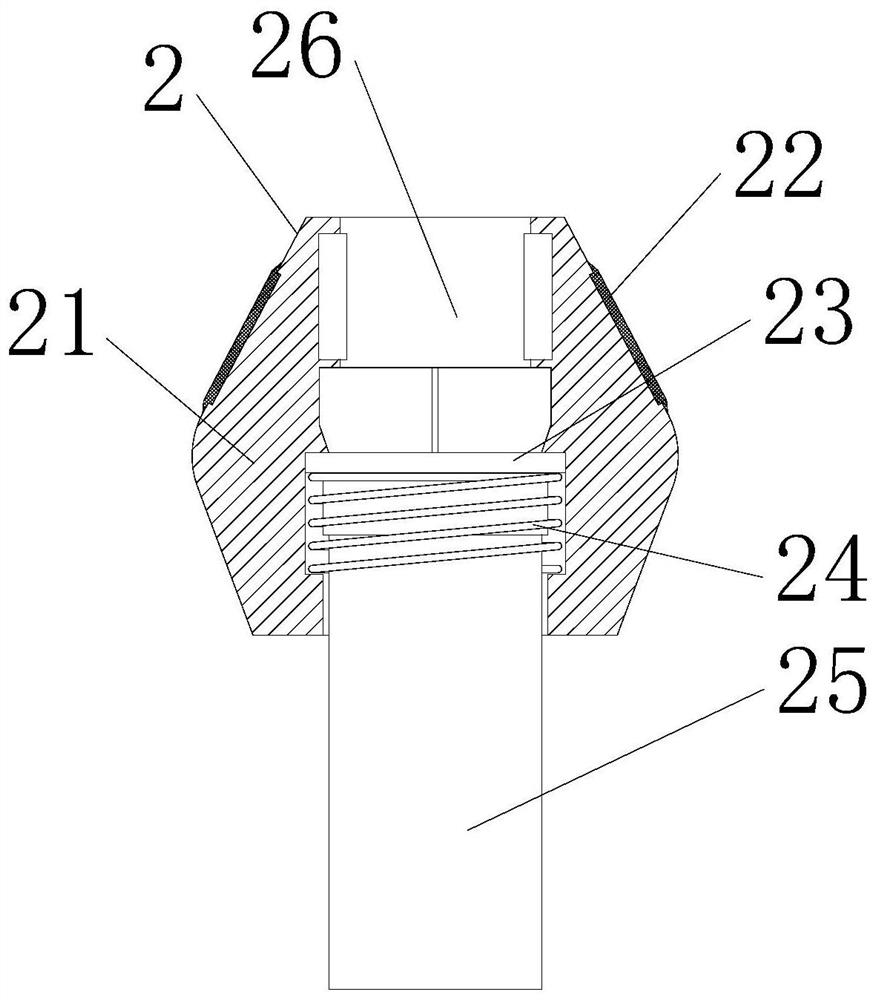

[0027]Such asFigure 1 - Figure 2 As shown, the present invention provides a tensile machine for a plastic rod ductility test, including a power control mechanism 1, a top fixed mounting finite mechanism 3 of the power control mechanism 1, and a stretch mechanism 4 is provided inside the limit mechanism 3, The stretch mechanism 4 is actively mounted inside the groove on both sides of the limit mechanism 3, and there is a clamping mechanism 2 between the stretch mechanism 4 and the power control mechanism 1, and the number of clamping mechanisms 2 is provided with two and mutual symmetry distribution. The bottom surface of the clamping mechanism 2 is fixedly welded, and the bottom surface of the other holding mechanism 2 is fixed to the bottom surface of the stretching mechanism 4, and the axis of the two clamping mechanisms 2 remains consistent, clamping The mechanism 2 includes a clamping body 21, and the outer wall of the holding body 21 is fixedly connected to a non-slip pad 22, a...

Embodiment 2

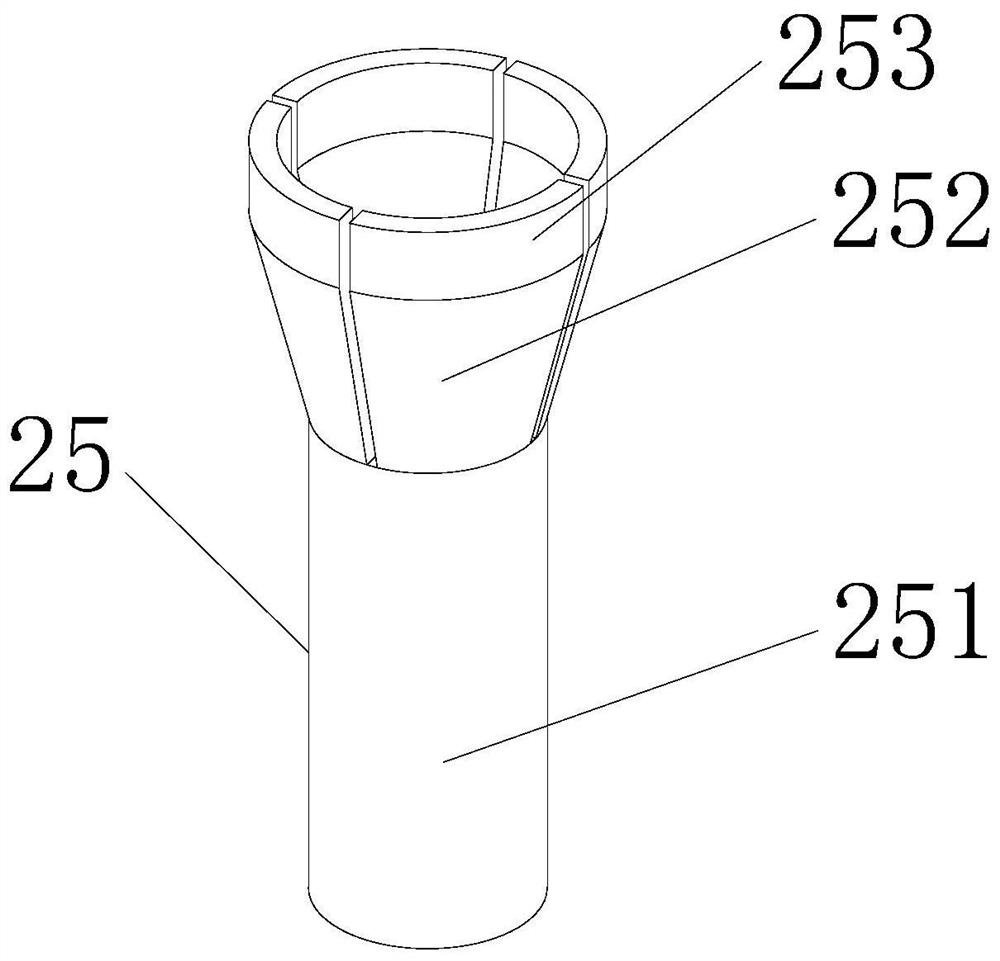

[0030]Such asFigure 3-5 As shown, in the basis of the first embodiment, the present invention provides a technical solution: the connection device 25 includes a support post 251, and the top portion of the support post 251 is fixedly connected to the clamping plate 252, and the number of clamping plate 252 is provided with four. And the equal distance is distributed, the top of the clamping plate 252 is fixedly coupled with the contact plate 253, and the support post 251 includes a cylinder 511, and the inner portion of the cylinder 511 is provided with a sound chamber 513, and the interior of the sound chamber 513 is provided with a vibration block 512, vibration. One end of the block 512 is fixedly coupled to the inner wall of the cylinder 511, and the inside of the vibration block 512 is provided with a knocking ball 121, a connecting rod 122, an active lumen 123, and one end of the connecting rod 122 and the inner wall of the vibration block 512. The other end of 122 is fixed to...

Embodiment 3

[0032]Such asFigure 6 As shown, in the basis of Example 1, Example 2, the present invention provides a technical solution: preferably, the contact plate 253 includes a plate body 531, and the plate body 531 is provided with an adsorption plate 532, and the adsorption plate 532 On one side, the active rod 533 is fixed, and the movable rod 533 is fixed to one side of the adsorption plate 532 fixedly connected to the pressure plate 535, and the inside of the plate body 531 is provided with a compression shrapnel 534, by using the adsorption plate 532, the compression shrapnel 534, the pressure plate 535 combined When the contact plate 253 is fixed to the outer wall of the plastic rod, the adsorption plate 532 is applied to the adsorbent plate 532, so that the adsorption plate 532 is extruded to the outer wall of the plastic rod, the inside of it. The air discharges forms a vacuum, and the outer atmospheric pressure is attached to the outer wall of the plastic rod, so that it is more st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com