Preparation method of carbon polymer-based polyhedral oligomeric silsesquioxane hybrid hydrophobic membrane

A technology of polymer and hydrophobic film, which is applied in the field of preparation of carbon polymer-based cage polysilsesquioxane hybrid hydrophobic film, which can solve the problem of high heat generation of electronic components, complicated spraying and film forming process, and the problem of hydrophobic film Low hardness and other problems, to achieve the effect of good hardness, surface gloss and decoration, high conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

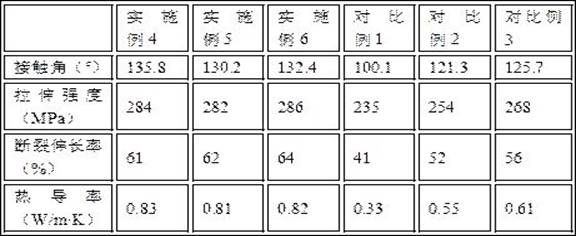

Examples

Embodiment 1

[0028] Preparation of modified graphene oxide:

[0029] Step S1, disperse nano-boron nitride in 5mol / L NaOH solution, then transfer to a reaction kettle and react at 120°C for 20h, so that the surface of boron nitride is hydroxylated, and wash with deionized water to make the pH reach neutral , and finally dried in an oven at 80°C for 4 hours to obtain hydroxylated boron nitride particles;

[0030] Step S2, dissolve KH-550 in deionized water, add octylphenyl polyoxyethylene ether, heat up to 50°C and stir for 30 minutes, add hydroxylated boron nitride particles and graphene oxide to it, heat up to 90°C for reaction 10h, filter, wash the filter cake 3 times with deionized water, dry and grind to obtain modified graphene oxide, wherein the mass ratio of deionized water, hydroxylated boron nitride particles, and graphene oxide is 20:5: 2. The amount of KH-550 is 10% of the total mass of hydroxylated boron nitride particles and graphene oxide, and the amount of octylphenyl polyox...

Embodiment 2

[0032] Preparation of modified graphene oxide:

[0033] Step S1, disperse nano-boron nitride in 5mol / L NaOH solution, then transfer to the reaction kettle and react at 120°C for 22h, so that the surface of boron nitride is hydroxylated, and wash with deionized water to make the pH reach neutral , and finally dried in an oven at 80°C for 4 hours to obtain hydroxylated boron nitride particles;

[0034] Step S2, dissolve KH-550 in deionized water, add octylphenyl polyoxyethylene ether, heat up to 50°C and stir for 40 minutes, add hydroxylated boron nitride particles and graphene oxide to it, heat up to 90°C for reaction 11h, filter, wash the filter cake 3 times with deionized water, dry and grind to obtain modified graphene oxide, wherein the mass ratio of deionized water, hydroxylated boron nitride particles, and graphene oxide is 25:5: 2. The amount of KH-550 is 12% of the total mass of hydroxylated boron nitride particles and graphene oxide, and the amount of octylphenyl poly...

Embodiment 3

[0036] Preparation of modified graphene oxide:

[0037] Step S1, disperse nano-boron nitride in 5mol / L NaOH solution, then transfer to the reaction kettle and react at 120°C for 24h, so that the surface of boron nitride is hydroxylated, and wash with deionized water to make the pH reach neutral , and finally dried in an oven at 80°C for 5 hours to obtain hydroxylated boron nitride particles;

[0038] Step S2, dissolve KH-550 in deionized water, add octylphenyl polyoxyethylene ether, heat up to 50°C and stir for 50 minutes, add hydroxylated boron nitride particles and graphene oxide to it, heat up to 90°C for reaction 12h, filter, the filter cake is washed 4 times with deionized water, dried and ground to obtain modified graphene oxide, wherein the mass ratio of deionized water, hydroxylated boron nitride particles, and graphene oxide is 30:5: 2. The amount of KH-550 is 15% of the total mass of hydroxylated boron nitride particles and graphene oxide, and the amount of octylphe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com