A kind of coating of austenitic stainless steel electrode, electrode and preparation method and application

A technology of austenitic stainless steel and welding rod, which is used in welding equipment, manufacturing tools, welding media, etc., can solve the problems of poor mechanical properties of austenitic welding rods, difficult to meet welding requirements, etc., to improve corrosion resistance and slag removal. Performance, beautiful effect of welding seam forming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

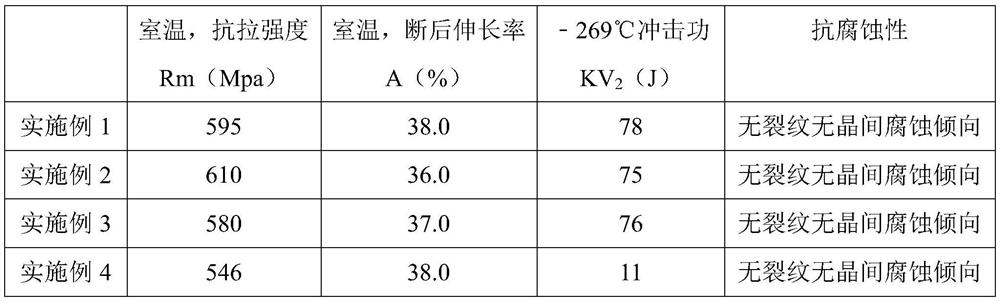

Examples

Embodiment 1

[0042] For an austenitic stainless steel electrode provided in this embodiment, the raw material composition of the coating of the electrode is: marble 7.0kg, barium carbonate 1.5kg, fluorite 4.0kg, fluoride 3.0kg, rutile 6.0kg, mica 0.1kg kg, electrolytic manganese 1.5kg, ferrotitanium 0.5kg, ferrosilicon 0.5kg, ferrochromium 3.0kg, metal nickel 5.0kg, ferromolybdenum 1.5kg, ferrochromium nitride 0.5kg and soda ash 0.2kg;

[0043] Among them, the chemical composition of the raw material of the coating of the electrode is calculated as a percentage by mass: CaCO2 in marble 3 The content is 98.20%, BaCO in barium carbonate 3 The content is 98.70%, CaF in fluorite 2 The content of F is 97.30%, the content of F in fluoride is 53.70%, the content of Na is 29.10%, and the content of TiO in rutile 2 The content is 95.50%, SiO in mica 2 The content is 48.10%, Al 2 O 3 The content of Mn in electrolytic manganese is 26.50%, the content of Mn in electrolytic manganese is 99.50%, th...

Embodiment 2

[0051] This example is different from Example 1 in that the weight of the raw material composition of the coating of the electrode is different, and the rest are the same as Example 1.

[0052] For an austenitic stainless steel electrode provided in Example 2, the coating materials of the electrode are by weight: marble 10.0kg, barium carbonate 0.1kg, fluorite 2.0kg, fluoride 5.0kg, rutile 4.0kg, mica 2.5kg kg, electrolytic manganese 1.0kg, ferrotitanium 1.5kg, ferrosilicon 0.5kg, ferrochromium 5.0kg, metal nickel 3.0kg, ferromolybdenum 0.1kg, ferrochromium nitride 1.0kg and soda ash 0.5kg;

Embodiment 3

[0054] This example is different from Example 1 in that the weight of the raw material composition of the coating of the electrode is different, and the rest are the same as Example 1.

[0055] For an austenitic stainless steel electrode provided in Example 3, the coating materials of the electrode are by weight: marble 8.5kg, barium carbonate 0.8kg, fluorite 3.0kg, fluoride 4.0kg, rutile 5.0kg, mica 1.4kg kg, electrolytic manganese 1.0kg, ferrotitanium 1.0kg, ferrosilicon 1.0kg, ferrochromium 4.0kg, metal nickel 4.0kg, ferromolybdenum 1.2kg, ferrochromium nitride 0.8kg and soda ash 0.4kg;

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com