Slag fluxing agent for molten steel and production method of slag fluxing agent

A production method and technology of thinning slag agent, which is applied in the field of molten steel thinning slag agent, can solve problems such as unsatisfactory thinning slag effect and affecting the quality of finished steel products, so as to improve the slag removal effect, strong slag gathering ability, and meet the needs of use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] A molten steel thin slag agent, which is composed of the following components in proportion by weight: 30 parts of potassium feldspar, 50 parts of low-sodium feldspar, and 20 parts of fused silica sand;

[0019] K in the potassium feldspar 2 O content 2 O content 3-5%, SiO 2 The content of > 65%; K in low sodium feldspar 2 O content 2 O content 2 The content of > 65%; SiO in fused silica sand 2 content > 99%;

[0020] The production method of molten steel thin slag agent, the steps are as follows:

[0021] 1) Process potassium feldspar and albite into fine powder with a particle size of 1-0mm, and process fused silica sand into fine powder with a particle size of 1.5-0mm;

[0022] 2) Stir and mix the above powder according to the proportion, and pack the finished product into bags.

Embodiment 2

[0024] A molten steel thin slag agent, which is composed of the following components in proportion by weight: 40 parts of potassium feldspar, 45 parts of low-sodium feldspar, and 15 parts of fused silica sand;

[0025] K in the potassium feldspar 2 O content 2 O content 3-5%, SiO 2 The content of > 65%; K in low sodium feldspar 2 O content 2 O content 2 The content of > 65%; SiO in fused silica sand 2 content > 99%;

[0026] The production method of molten steel thin slag agent, the steps are as follows:

[0027] 1) Process potassium feldspar and albite into fine powder with a particle size of 1-0mm, and process fused silica sand into fine powder with a particle size of 1.5-0mm;

[0028] 2) Stir and mix the above powder according to the proportion, and pack the finished product into bags.

Embodiment 3

[0030] A molten steel thin slag agent, which is composed of the following components in proportion by weight: 50 parts of potassium feldspar, 40 parts of low-sodium feldspar, and 10 parts of fused silica sand;

[0031] K in the potassium feldspar 2 O content 2 O content 3-5%, SiO 2 The content of > 65%; K in low sodium feldspar 2 O content 2 O content 2 The content of > 65%; SiO in fused silica sand 2 content > 99%;

[0032] The production method of molten steel thin slag agent, the steps are as follows:

[0033] 1) Process potassium feldspar and albite into fine powder with a particle size of 1-0mm, and process fused silica sand into fine powder with a particle size of 1.5-0mm;

[0034] 2) Stir and mix the above powder according to the proportion, and pack the finished product into bags.

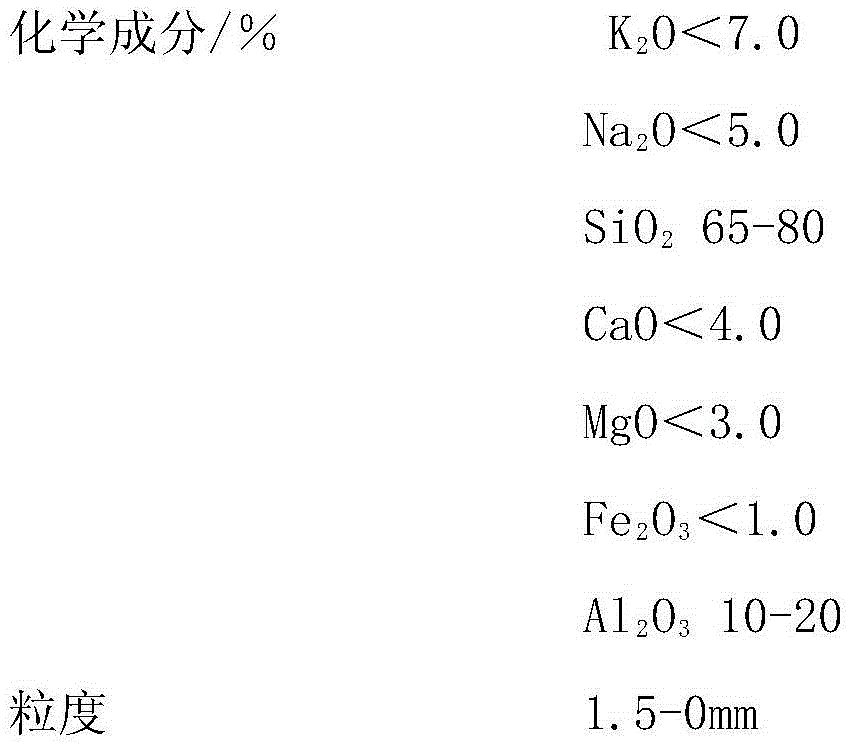

[0035] The physical and chemical indicators of the molten steel thin slag agent finished product of above-mentioned embodiment 1-3 are:

[0036]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com