High-strength lightweight composite mortar board

A composite mortar, high-strength technology, applied in building components, ceramic molding machines, insulation, etc., can solve problems such as wrinkles, unevenness, and low molding quality of composite mortar boards, shorten service life, avoid excessive stress concentration, and achieve Effect of Resistance Continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

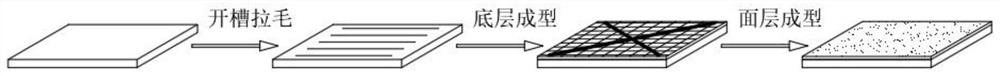

[0045] see figure 1 , a kind of high-strength lightweight composite mortar board, its preparation method comprises the following steps:

[0046] S1. Groove and roughen the surface of the insulation board, and then apply mortar to the grooved surface of the insulation board to form the bottom layer;

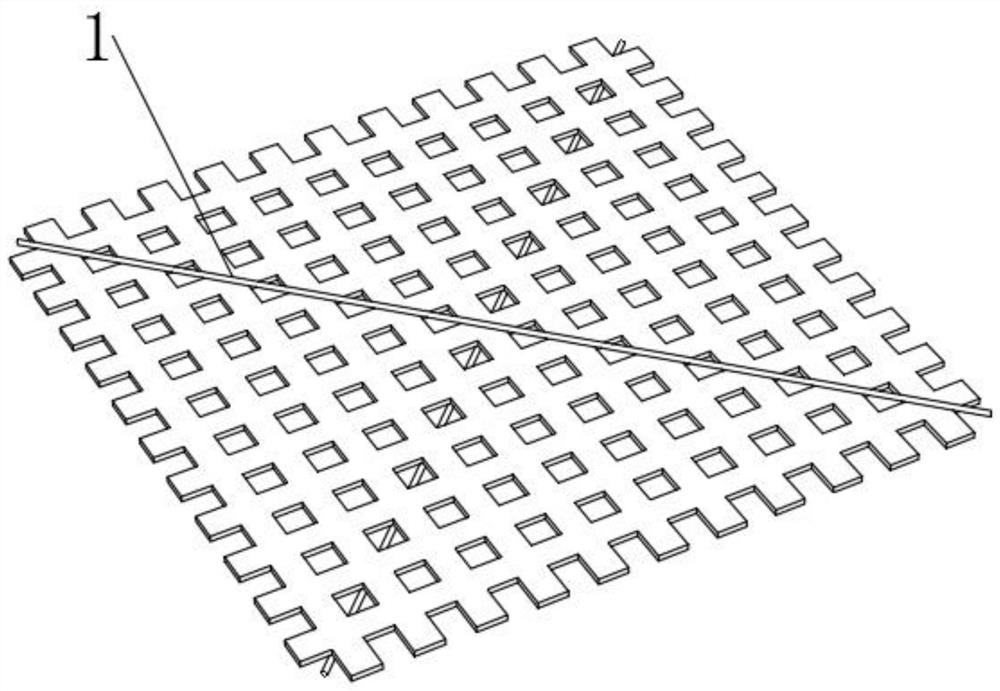

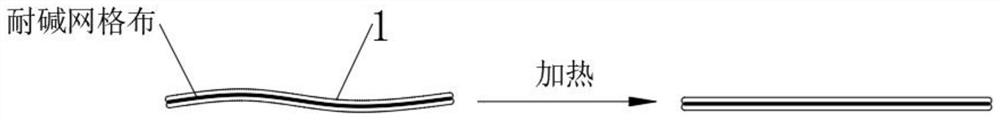

[0047] S2. Lay an alkali-resistant grid cloth on the bottom layer of the mortar, and a pair of tensile bars 1 are distributed obliquely and symmetrically on the alkali-resistant grid cloth;

[0048] S3, heating the stretching strip 1 to force its inflatable bulge to stretch, so as to independently level the alkali-resistant grid cloth;

[0049] S4. Coat the mortar again on the alkali-resistant grid cloth, and then sequentially maintain, wash the edge, trim it, and finally store it in the warehouse.

[0050] see figure 2 , the stretching strips 1 are distributed diagonally on the alkali-resistant mesh cloth, and a pair of stretching strips 1 are respectively located on the uppe...

Embodiment 2

[0056] see Figure 6-8 , compared with Example 1, the inner heat conduction wire 12 is replaced by a plurality of inner drum airbags 14a and a plurality of hot-melt particles 15, and ammonium bicarbonate powder is filled in the inner drum airbags 14a, and the inner drum airbags 14a are evenly distributed in the hollow The inner side of the bag strip 11 is fixedly connected with its inner wall, and the hot-melt particles 15 are evenly distributed between the inner drum air bags 14a. When heated, the ammonium bicarbonate in the inner drum air bag 14a decomposes rapidly to generate gas to force it to expand to both sides, and at the same time heat melt The particles 15 are heated and melted into a flowable state, and are concentrated between a pair of adjacent inner drum air cells 14a under the extrusion action of the inner drum air cells 14a. While realizing the stretching of the hollow cell strip 11, the adjacent inner drum cells Blocks with certain hardness are formed between ...

Embodiment 3

[0060] see Figure 9-10 , compared with embodiment 1, the inner heat conduction wire 12 is replaced by a plurality of internal control airbags 14b, the internal control airbags 14b are evenly distributed inside the hollow bag bar 11 and fixedly connected to its inner wall, and the internal control airbags 14b include an inner drum airbag 14a and a pair of air leakage Compared with Example 2, the hot-melt particles 15 are discarded and the air leakage point is introduced. The air leakage point is symmetrically inlaid at the upper and lower ends of the inner drum airbag 14a, and the air leakage point extends to the outside of the hollow bag strip 11. Ammonium bicarbonate The powder is filled in the inner drum airbag 14a, and the inner drum airbag 14a is first heated to generate gas for self-expansion, and squeezes the air in the hollow bag strip 11 to fill, and finally realizes the bulge stretching of the hollow bag strip 11, and under certain conditions The air leakage phenomen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com