Optical soliton optical gyroscope system

An optical gyroscope and optical soliton technology, applied in the field of optics, can solve problems affecting gyroscope performance indicators, thermal non-reciprocity noise, uneven temperature field distribution, etc., to improve output accuracy, low bit error rate, and reduce related optical noise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

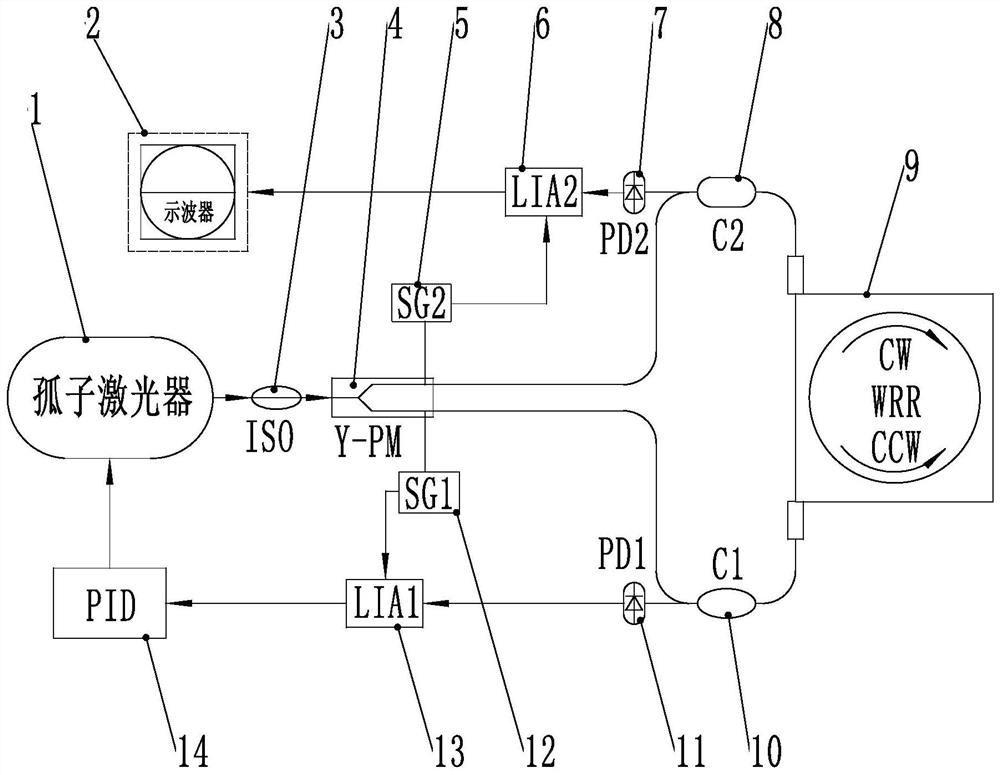

[0021] A kind of optical soliton optical gyro system of the present invention is further described below in conjunction with accompanying drawing and specific embodiment:

[0022] figure 1 It is a schematic diagram of a connection wire frame of an optical soliton optical gyroscope system of the present invention. In the figure, the optical soliton optical gyro system includes a soliton laser 1, and the soliton laser 1 is connected with an optical isolator 3, and the optical isolator 3 is connected with a modulation beam splitter 4, and the modulation beam splitter 4 is connected in parallel with a first optical The circulator 10 and the second optical circulator 8, the two optical circulators 8 and 10 are merged and connected to the waveguide resonator 9, the first optical circulator 10 is also connected with the first photodetector 11, and the second optical circulator 8 is also connected with the second photodetector 7, and the first photodetector 11 is connected with the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com