Low-cobalt high-strength hard alloy and preparation method thereof

A cemented carbide and high-strength technology, which is applied in the field of low-cobalt and high-strength cemented carbide and its preparation, can solve the problems of reducing work efficiency, construction project progress, wear resistance, etc. Good breaking strength and abrasion resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] On the other hand, a method for preparing low-cobalt high-strength cemented carbide specifically comprises the following steps:

[0043] Ingredients: put the composite hard phase and binder phase in the above parts by weight into the ball mill cylinder;

[0044] Ball milling: Add hexane or alcohol, paraffin, stearic acid into the ball mill cylinder, cover the ball mill cylinder, start the ball mill, and ball mill for 24-60 hours;

[0045] Preparation of mixed pellets: discharge slurry through filtration, carry out spray drying and granulation of slurry through spray tower to obtain the required mixed pellets for pressing;

[0046] Compression: Press the mixed pellets through a mold and a press to obtain the required semi-finished carbide blank;

[0047] Sintering: put the semi-finished cemented carbide blank into a pressure sintering furnace for high temperature sintering;

[0048] Complete the preparation:

[0049] In some possible implementations, during the pressi...

Embodiment 1

[0053] In this example, the specific proportion of high-strength cemented carbide is: 94 parts of high-temperature reduction and high-temperature carbonized tungsten carbide with a Fibonacci particle size of 3.10 μm to 3.60 μm, 6 parts of cobalt powder, and a total of 100 parts; 2 parts of paraffin, 0.05 part of stearic acid, 400 ml / kg of hexane or alcohol.

[0054] The concrete steps of preparation method are as follows:

[0055] Step 1: Ingredients;

[0056] Weigh tungsten carbide A and cobalt powder with a Fibonacci particle size of 3.10 μm to 3.60 μm and put them into the ball mill cylinder according to the weight ratio, wherein the total carbon of tungsten carbide is adjusted with tungsten powder or carbon black, and the ratio of ingredients to balls is 4 :1.

[0057] Step two: ball milling;

[0058] Add 400 ml / kg of hexane or alcohol, 2 parts of paraffin, and 0.05 part of stearic acid into the ball mill cylinder of the above ingredients. After covering the ball mill c...

Embodiment 2

[0066] Embodiment 2-implementation 4 uses the same raw materials as in embodiment 1, and controls different sintering temperatures and relative cobalt-cobalt magnetic percentages to achieve preparation;

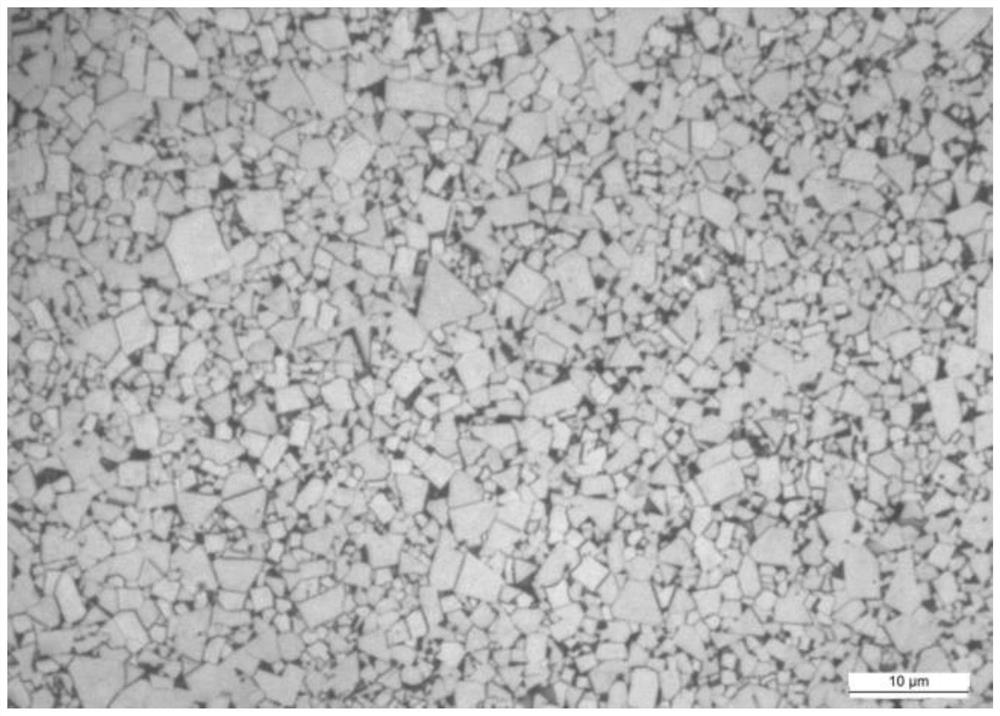

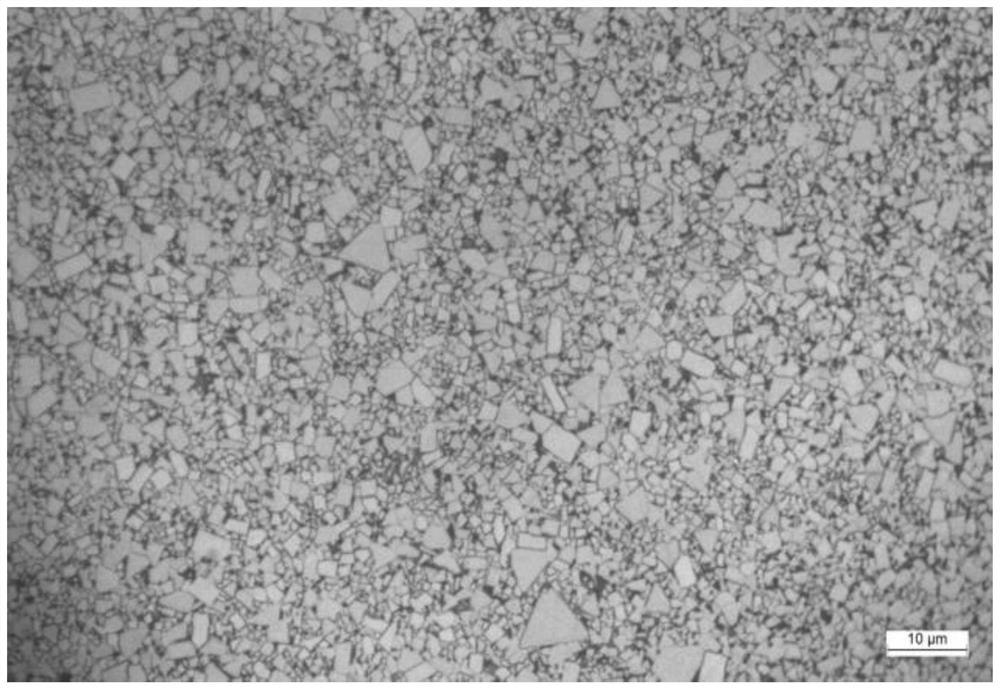

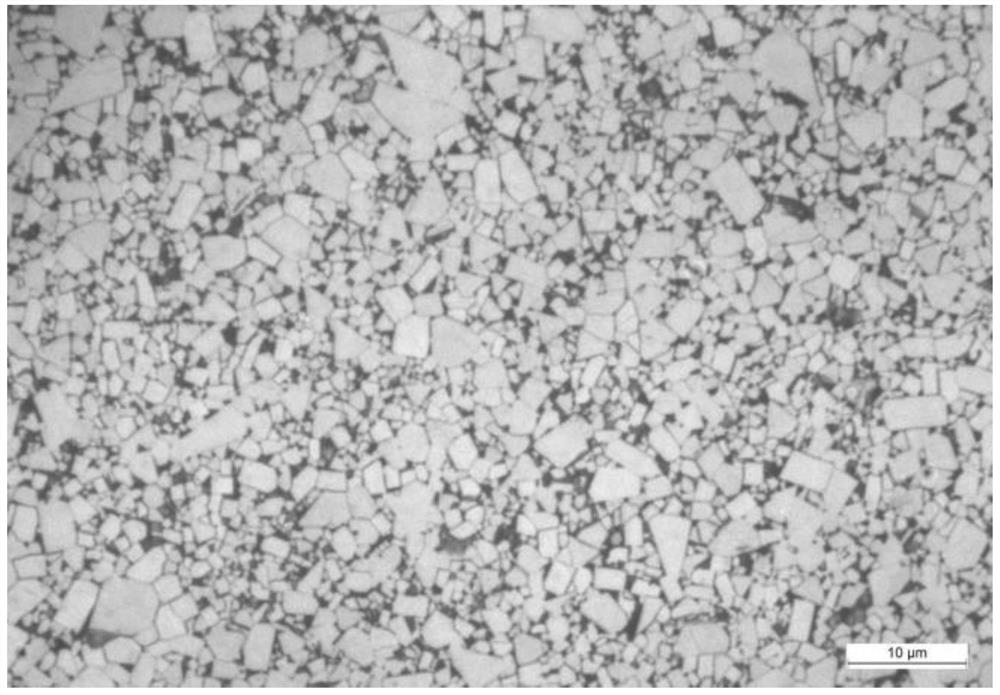

[0067] The difference between embodiment 2-implementation 4 and embodiment 1 is that the sintering temperature and the relative cobalt-cobalt magnetic percentage are different. After the preparation is completed, the green body is sent for inspection. Figure 1-Figure 4 It is the metallographic picture of embodiment 1-embodiment 4 successively, and its physical properties are as such

[0068] Table 1 shows:

[0069]

[0070] Table 1

[0071] As can be seen from the data in Table 1, in Example 1-Example 4, the same tungsten carbide has the same cobalt content, and the mixture made by ball milling has different sintering temperatures and the influence of cobalt magnetism on alloy performance. In the case of non-decarburization, the tungsten in the alloy plays a role of sol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com