Landfill leachate treatment process

A landfill leachate and treatment process technology, which is applied in the field of leachate concentrate evaporation device, can solve the problems of high energy consumption, equipment corrosion, scaling, etc., and achieve the advantages of prolonging the cleaning cycle, solving corrosion problems, and slowing down the scaling rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

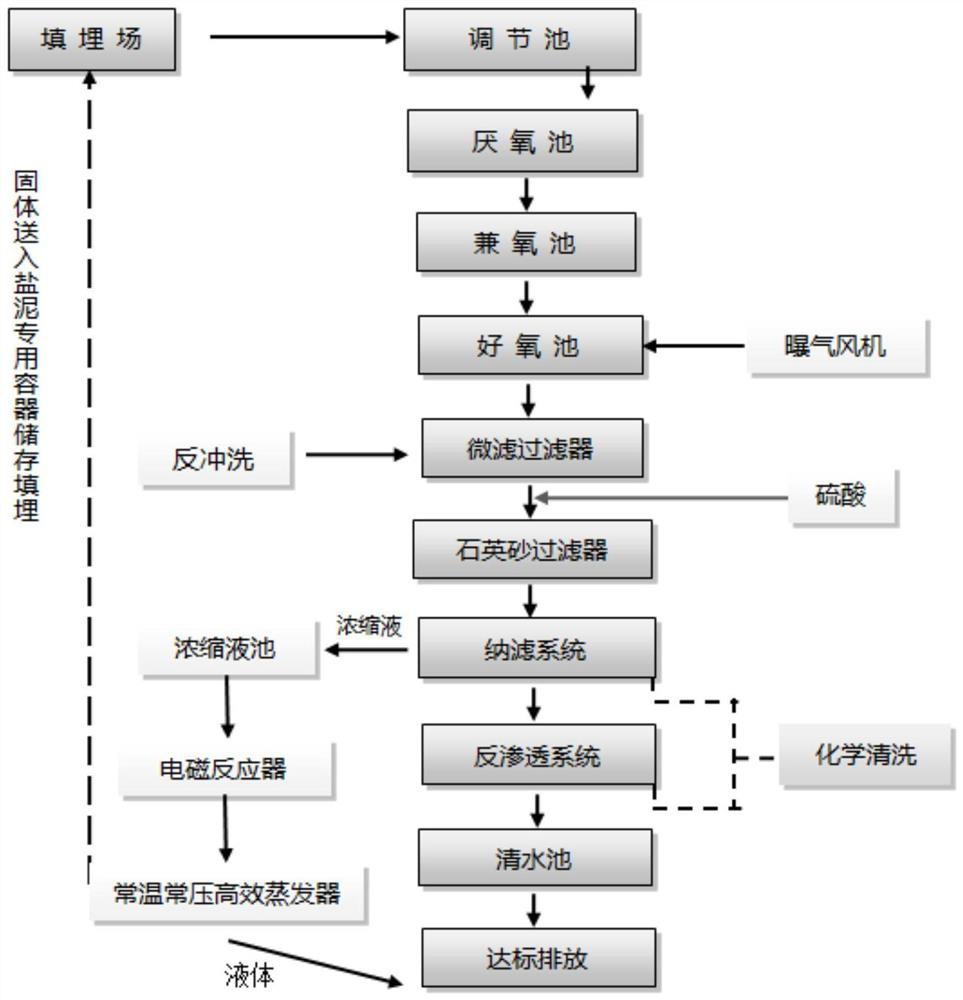

[0027] Embodiment 1, a kind of treatment process of landfill leachate figure 1 As shown, in step 1, the landfill leachate is sent to the biochemical treatment system, first passes through the adjustment tank, settles and separates the landfill leachate, and at the same time performs water quality homogenization and water volume adjustment; after that, the regulated The landfill leachate adjusted by the tank is put into the anaerobic tank and evenly mixed with the anaerobic granular sludge. Most of the organic matter is converted into biogas here, and the unremoved organic matter in the landfill leachate is further degraded by the anaerobic granular sludge. Decompose the macromolecular refractory organic matter into easily degradable organic matter, so that the landfill leachate can be better purified; put the landfill leachate after anaerobic treatment into the facultative tank, the so-called facultative refers to the difference between anaerobic and good A state between oxyge...

Embodiment 2

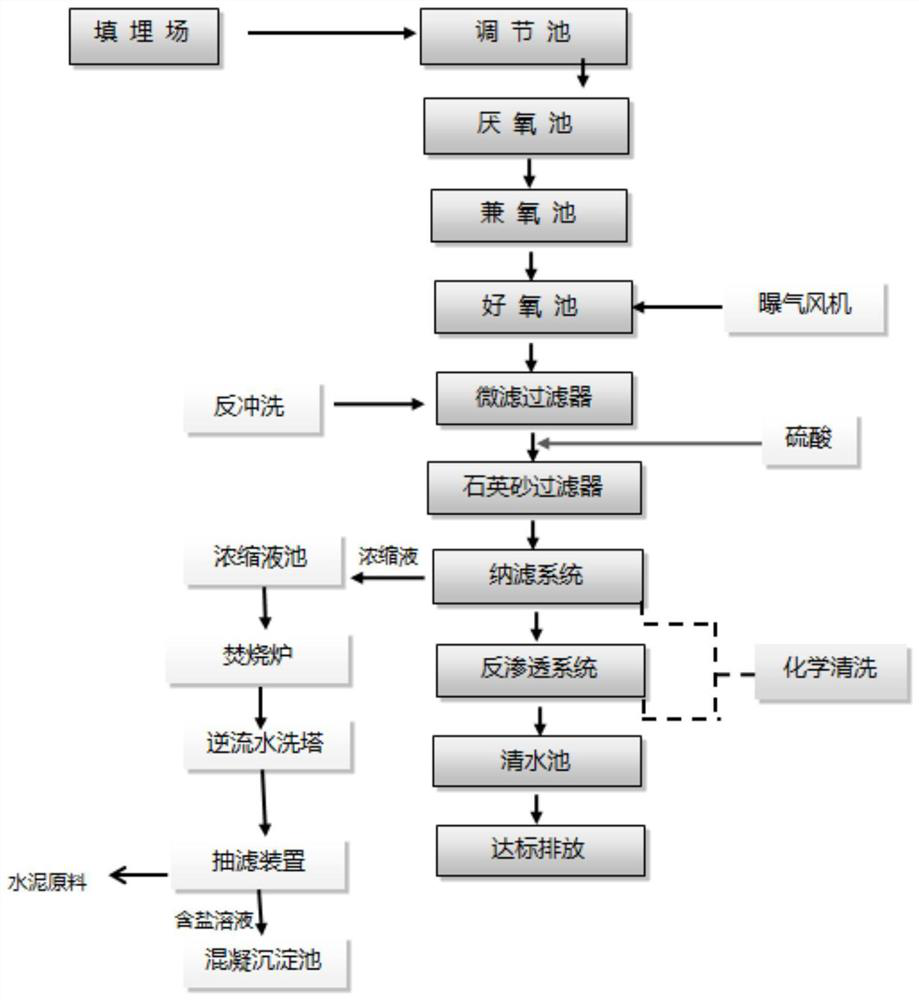

[0031] Embodiment 2, a kind of treatment process of landfill leachate such as figure 2 As shown, in step 1, the landfill leachate is sent to the biochemical treatment system, first passes through the adjustment tank, settles and separates the landfill leachate, and at the same time performs water quality homogenization and water volume adjustment; after that, the regulated The landfill leachate adjusted by the tank is put into the anaerobic tank and evenly mixed with the anaerobic granular sludge. Most of the organic matter is converted into biogas here, and the unremoved organic matter in the landfill leachate is further degraded by the anaerobic granular sludge. Decompose the macromolecular refractory organic matter into easily degradable organic matter, so that the landfill leachate can be better purified; put the landfill leachate after anaerobic treatment into the facultative tank, the so-called facultative refers to the difference between anaerobic and good A state betw...

Embodiment 3

[0035] The difference between Example 3 and Example 2 is that the washing water is slightly alkaline water, and the ratios of washing water to fly ash are 4:1, 3:1 and 3:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com