Preparation method of oriented nanofiber nerve conduit

A nerve conduit and nanofiber technology, used in pharmaceutical formulations, medical science, prostheses, etc., can solve the problems of easily causing inflammation in surrounding tissues, slow degradation rate, and acidic degradation products, achieving excellent biocompatibility, promoting The effect of repair and preparation method is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A method for preparing an oriented nanofiber nerve guide, comprising the following steps:

[0033] 1) The directional fiber nerve conduit was prepared by electrospinning technology. Take 0.3g of gelatin, mix it with polylactic acid at a mass ratio of 1:1, dissolve it in 10ml of hexafluoroisopropanol to make a spinning solution, then add 40ng of nerve growth factor NGF and 10mg of astragalus polysaccharide, stir magnetically for 0.5-2h and then sonicate Degas for 10 minutes; add the above spinning solution into a 10ml syringe, connect a 21G stainless steel nozzle, set the distance between the nozzle and the receiving plate to 15cm, use a voltage of 9-12kV, a negative voltage of 3KV, a flow rate of 1.0ml / h, and a receiving speed of 2400r / min as the condition for electrospinning. The prepared samples were vacuum dried for 24 hours to remove residual organic solvents.

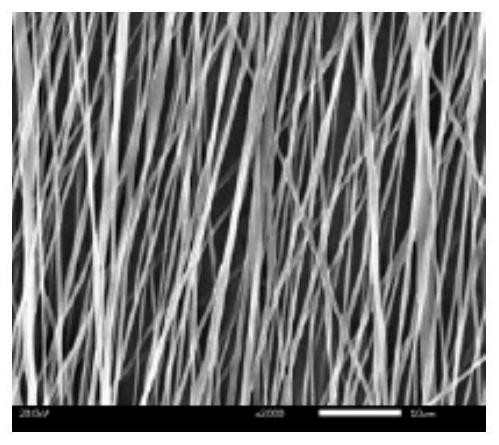

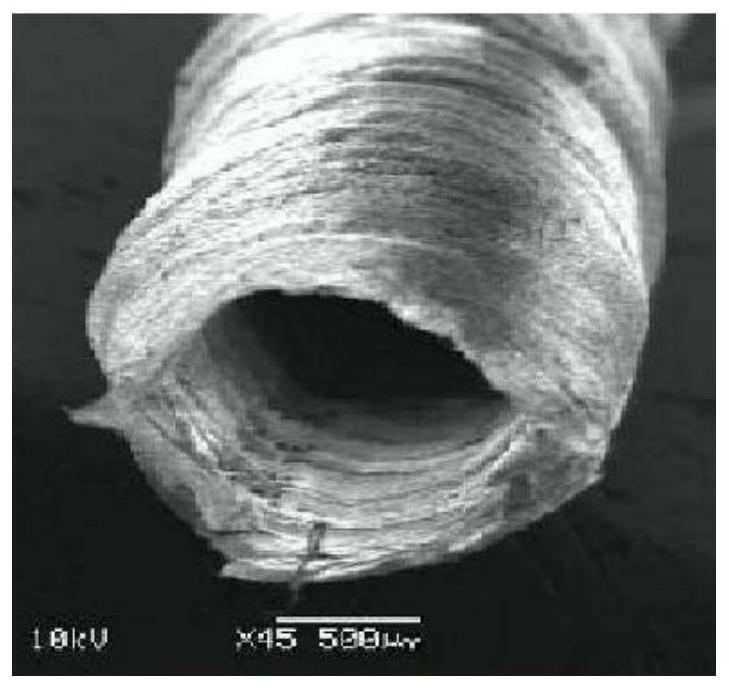

[0034] figure 1 This is the SEM picture of the prepared nerve guide, in which the fibers are oriented...

Embodiment 2

[0070] A method for preparing an oriented nanofiber nerve guide, comprising the following steps:

[0071] 1) The directional fiber nerve conduit was prepared by electrospinning technology.

[0072] Take 0.3g of polylactic acid, mix it with gelatin at a mass ratio of 2:1, dissolve it in 10ml of hexafluoroisopropanol to make a spinning solution, then add 30ng of nerve growth factor NGF and 15mg of astragalus polysaccharide, stir magnetically for 0.5-2h and then sonicate Degas for 10 minutes; add the above spinning solution into a 10ml syringe, connect a 21G stainless steel nozzle, set the distance between the nozzle and the receiving plate to 15cm, use a voltage of 9-12kV, a negative voltage of 3KV, a flow rate of 1.0ml / h, and a receiving speed of 2400r / min as the condition for electrospinning. The prepared samples were vacuum dried for 24 hours to remove residual organic solvents.

[0073] 2) Synthesis and cross-linking of nerve conduits

[0074] The length of the nerve gui...

Embodiment 3

[0076] A method for preparing an oriented nanofiber nerve guide, comprising the following steps:

[0077] 1) The directional fiber nerve conduit was prepared by electrospinning technology.

[0078] Mix 0.3g of polylactic acid and gelatin at a mass ratio of 4:1, dissolve in 10ml of hexafluoroisopropanol to make a spinning solution, then add 60ng of nerve growth factor NGF and 8mg of astragalus polysaccharide, stir magnetically for 0.5-2h, and then ultrasonically remove Gas for 10 minutes; add the above spinning solution into a 10ml syringe, connect a 21G stainless steel nozzle, set the distance between the nozzle and the receiving plate to 15cm, use a voltage of 9-12kV, a negative voltage of 3KV, a flow rate of 1.0ml / h, and a receiving speed of 2400r / h min as the condition for electrospinning. The prepared samples were vacuum dried for 24 hours to remove residual organic solvents.

[0079] 2) Synthesis and cross-linking of nerve conduits

[0080] The length of the directiona...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com