Self-supporting MgTiO3 nanofiber chemical warfare agent degradable material and preparation method thereof

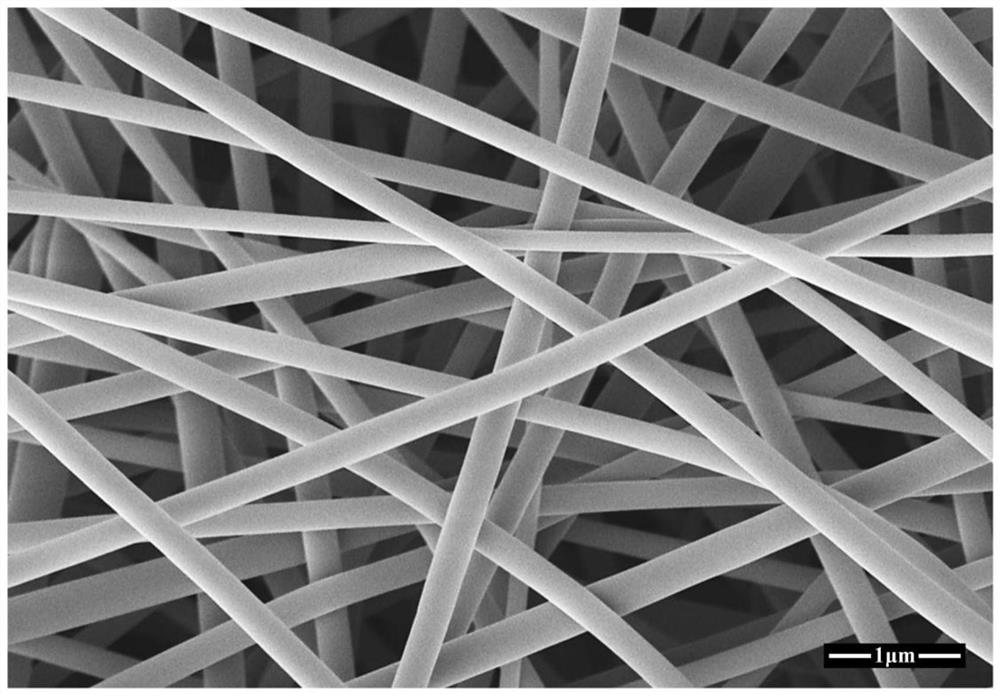

A technology of nanofibers and chemical warfare agents, which is applied in the fields of fiber chemical characteristics, heating/cooling fabrics, textiles and papermaking, etc. It can solve the problems of low content of inorganic components in precursor solutions, difficulty in obtaining self-supporting nanofibers, poor fiber continuity, etc. problem, to achieve the effect of good continuity, uniform diameter, and high-efficiency degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A self-supporting MgTiO 3 The preparation method of nanofiber chemical warfare agent degradation material, the steps are as follows:

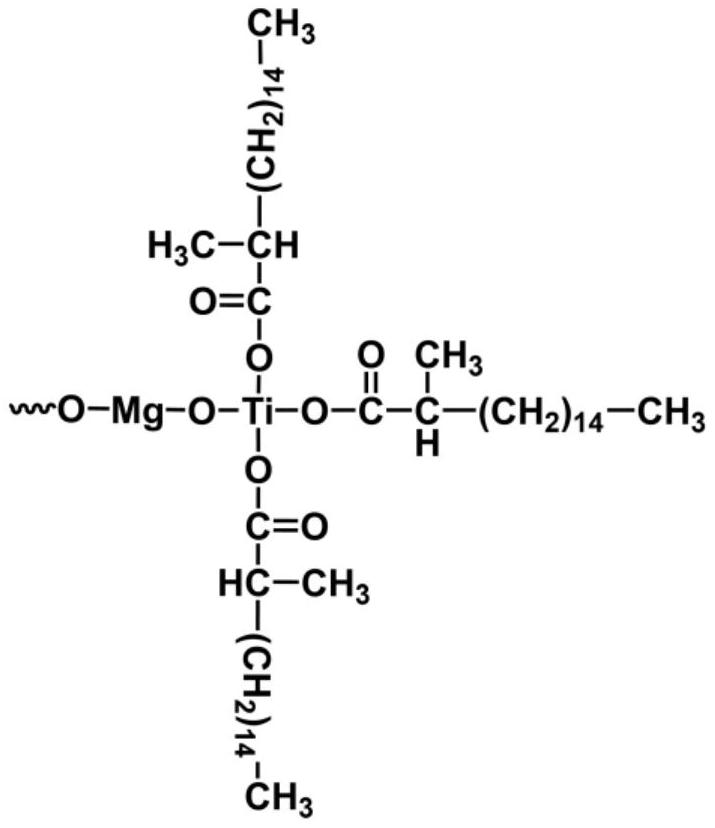

[0032] (1) Dissolve the magnesium salt anhydrous magnesium chloride and the grain inhibitor tin tetrachloride in the solvent N,N-dimethylformamide in turn, stir for 30 minutes, and then add the titanate coupling agent triisostearyl titanium The acid ester was stirred for 60 min to obtain a precursor solution. Wherein, the molar ratio of magnesium salt, titanate coupling agent and grain inhibitor in the solution is 1:1:0.08, the ratio of the total mass of magnesium salt and titanate coupling agent to solvent is 10g:35mL, the precursor The body solution has a long-chain molecular chain structure, and its structural formula is as follows:

[0033]

[0034] (2) The above precursor solution was prepared into a precursor fiber film by electrospinning technology. The process parameters of electrospinning were: ambient temperature 23°C, rel...

Embodiment 2

[0039] A self-supporting MgTiO 3 The preparation method of the nanofiber chemical warfare agent degradation material, the specific steps are:

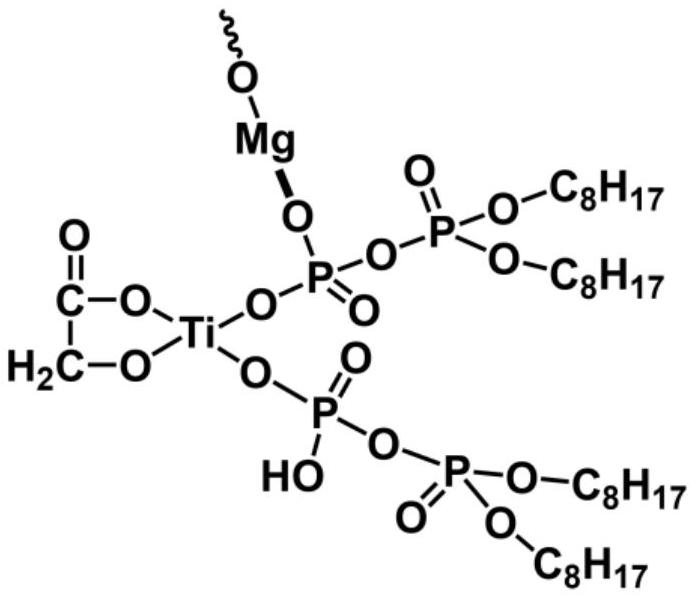

[0040] (1) Dissolve the magnesium salt anhydrous magnesium chloride and the grain inhibitor tin tetrachloride in the solvent N,N-dimethylformamide in turn, stir for 40 minutes, and then add titanate coupling agent oxyacetic acid chelated titanium The ester was stirred for 80 min to obtain a precursor solution. Wherein, the molar ratio of magnesium salt, titanate coupling agent and grain inhibitor in the solution is 1:1:0.09, the ratio of the total mass of magnesium salt and titanate coupling agent to solvent is 10g:46mL, the precursor The titanate coupling agent and magnesium ions in the bulk solution form a multi-component ring complex, and its structural formula is as follows;

[0041]

[0042] (2) The above precursor solution was prepared into a precursor fiber film by electrospinning technology. The process parameters of elect...

Embodiment 3

[0046] A self-supporting MgTiO 3 The preparation method of the nanofiber chemical warfare agent degradation material, the specific steps are:

[0047] (1) Dissolve the magnesium salt magnesium sulfate monohydrate and the grain inhibitor zirconium acetate in sequence in the solvent glycerol, stir for 45 minutes, and then add the titanate coupling agent isopropyl tris(dioctyl pyrophosphate acyloxy Base) titanate was stirred for 85min to obtain a precursor solution. Wherein, the molar ratio of magnesium salt, titanate coupling agent and grain inhibitor in the solution is 1:1:0.15, and the ratio of the total mass of magnesium salt and titanate coupling agent to solvent is 10g:45mL;

[0048] (2) The above precursor solution was prepared into a precursor fiber film by electrospinning technology. The process parameters of electrospinning were: ambient temperature 25°C, relative humidity 46%, perfusion speed 2mL / h, voltage 49kV, receiving device and The distance between the spinnere...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| softness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com