3-azido methyl-3-methyloxetane-tetrahydrofuran energetic copolyether with alternating multi-block structure and synthesis method thereof

A methyl oxetane and azidomethyl technology, which is applied in the field of 3-azidomethyl-3-methyl oxetane-tetrahydrofuran copolymer and its synthesis, can solve the problem of carrying atoms in the main chain Low temperature, poor mechanical properties and process performance at low temperature, etc., to achieve the effect of controllable mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Add 1.5g of PAMMO (Mn=216, 6.94mmol), 5mL of THF, and 2.0g of KOH (35.65mmol) into the round-bottomed flask in sequence, and raise the temperature of the system to 65°C under constant temperature reflux. Then, 2.0 g (3.80 mmol) of tosylate-terminated polytetrahydrofuran and 5 mL of THF solution were slowly dropped into the above-mentioned reflux system, and the system continued to react at 65° C. for 72 h after the addition was completed. After the reaction was completed, THF was filtered and rotary evaporated, and the crude product was dissolved in dichloromethane, washed with saturated brine until neutral, then dried by adding anhydrous sodium sulfate, suction filtered, and rotary evaporated. Finally, petroleum ether with a boiling point of 60-90° C. and methanol were added in sequence to wash and rotary evaporate to obtain a yellow viscous liquid (1.02 g).

[0029] Structure Identification:

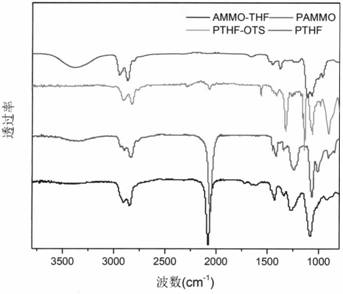

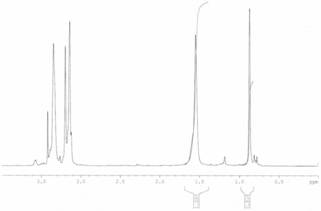

[0030] FT-IR infrared: After PTHF undergoes p-tosylation to obtain termina...

Embodiment 2

[0034] Add 1.0g PAMMO (Mn=225, 4.44mmol), 5mL THF, and 2.0g KOH (35.65mmol) into the round-bottomed flask in turn, and raise the temperature of the system to 65°C under constant temperature reflux. Then, 1.0 g (2.50 mmol) of tosylate-terminated 1,4-butanediol and 5 mL of THF solution were slowly dropped into the above-mentioned reflux system, and the system continued to react at 65° C. for 48 h after the addition was completed. After the reaction was completed, THF was filtered and rotary evaporated, and the crude product was dissolved in dichloromethane, washed with saturated brine until neutral, then dried by adding anhydrous sodium sulfate, suction filtered, and rotary evaporated. Finally, petroleum ether with a boiling point of 60-90° C. and methanol were added successively to wash and rotary evaporate to obtain a yellow viscous liquid (0.41 g).

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com