Colored waterborne polyurethane and preparation method thereof

A water-based polyurethane and color technology, used in textiles and papermaking, can solve the problems of difficult reaction control, limited practical application, difficult control of synthesis process, etc., to solve the problem of low dye reactivity and poor color fastness, improve reaction efficiency and Utilization efficiency, the effect of solving the color fastness problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

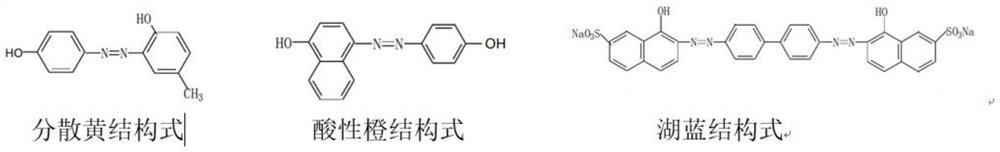

[0038] A colored water-based polyurethane and its preparation method, comprising the following components, step 1: preparation of colored polyester polyol, prepared from the following raw materials in parts by weight: 20-100 parts of dibasic acid, 30 parts of small molecule chain extender -110 parts, 5-20 parts of dyes containing active hydroxyl groups, 0.1-0.5 parts of tetrabutyl titanate, wherein the molar ratio of hydroxyl and carboxyl groups is 1.1-1.3:1; Step 2: The preparation of colored water-based polyurethane consists of the following parts by weight Prepared from raw materials: 50-200 parts of diisocyanate, 150-350 parts of conventional diol, 50-120 parts of colored polyester diol, 1-20 parts of small molecule chain extender, 10-20 parts of hydrophilic chain extender 45 parts, 400-1200 parts of deionized water.

[0039] A kind of colored water-based polyurethane and its preparation method as described above, the said dibasic acid is any one of adipic acid, sebacic ac...

Embodiment 1

[0049] Step 1: Preparation of colored polyester polyol, (1) Weigh 100 parts of adipic acid, 51 parts of ethylene glycol, 10 parts of disperse yellow dye, and 0.4 part of tetrabutyl titanate into a four-necked flask During the process, the temperature was raised to 80°C, and the materials were stirred evenly by means of ultrasonic dispersion and stirring; (2) gradually raised to 240°C for 4 hours of reaction; (3) reduced to -0.09Mpa to distill out water and residual monomers, and detect The water content is less than 0.05%, the acid value is less than 1 mgKOH / g, and the hydroxyl value is 52-58 mgKOH / g, and the colored polyester polyol is obtained.

[0050] Step 2: Preparation of colored water-based polyurethane (1) 300 parts of polytetrahydrofuran ether diol (number average molecular weight is 2000), 100 parts of colored polyester polyol of step 1, and 25 parts of dimethylol propionic acid in a vacuum at 120°C Dehydrate for 1 hour, lower the temperature to 50°C, add 23 parts of...

Embodiment 2

[0052] Step 1: Preparation of colored polyester polyol, (1) 60 parts of adipic acid, 50 parts of sebacic acid, 71 parts of 1,4-butanediol, 13 parts of acid orange dye containing active hydroxyl groups, Weigh 0.3 part of tetrabutyl titanate into a four-necked flask, heat up to 80°C, and stir the material evenly by means of ultrasonic dispersion and stirring; (2) Gradually raise the temperature to 240°C for 4 hours; (3) reduce Water and residual monomers are distilled out under pressure, and the water content is less than 0.05%, the acid value is less than 1 mgKOH / g, and the hydroxyl value is 52-58 mgKOH / g, and the colored polyester polyol is obtained.

[0053] Step 2: the preparation of colored water-based polyurethane (1) with 205 parts of polytetrahydrofuran diols (number-average molecular weight is 1000), 100 parts of polypropylene glycol (number-average molecular weight is 2000), 80 parts of colored polyester polyols of step 1 and 30 parts 1 part of dimethylolpropionic acid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com