Vinylidene-fluoride-based polymer composition obtained using non-fluorinated surfactant and production method therefor

A surfactant and vinylidene fluoride technology, applied in battery pack parts, structural parts, electrical components, etc., can solve problems such as restricting the use of fluorinated surfactants, achieve good polymerization stability, and is not easy to foam , the effect of high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

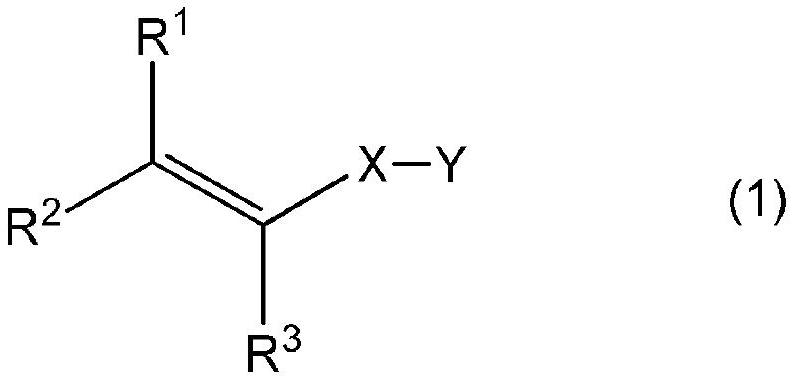

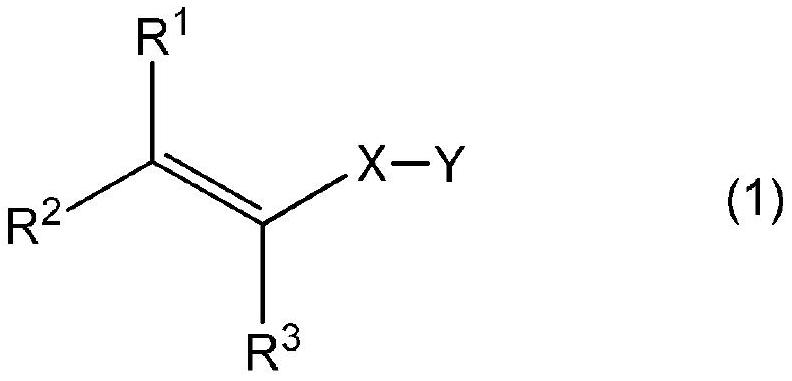

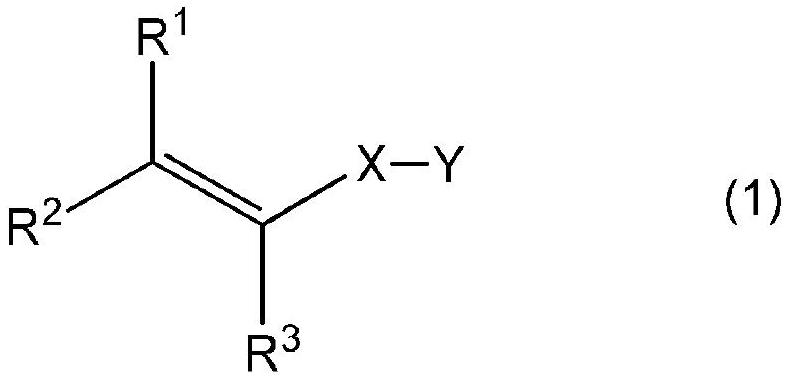

Method used

Image

Examples

Embodiment 1

[0155] 380 parts by mass of ion-exchanged water were put into the autoclave, and nitrogen bubbling was performed for 30 minutes to deaerate. Next, 0.25 parts by mass of disodium hydrogen phosphate and EMULGEN (trade name; manufactured by Kao Corporation. The same applies hereinafter) LS-1100.0019 parts by mass were charged, pressurized to 6.5 MPa, and replaced with nitrogen three times. Then, 0.2 mass parts of ethyl acetate, 28 mass parts of vinylidene fluoride (VDF), and 7 mass parts of hexafluoropropylene (HFP) were added to the said autoclave. While stirring, the temperature was raised to 80°C. Then, a 5% by mass aqueous solution of ammonium persulfate was added so that the amount of ammonium persulfate became 0.1 parts by mass, and polymerization was initiated. The pressure inside the kettle at this time was set at 2.5 to 5 MPa. After the start of the reaction, when the pressure in the tank dropped to 2.5 MPa, 65 parts by mass of VDF was continuously added so that the pr...

Embodiment 2

[0157] Except having changed the quantity of EMULGEN LS-110 into 0.003 mass part from 0.0019 mass part, it superposed|polymerized similarly to Example 1, and obtained the latex. The solid content concentration of the obtained latex was 19.2 mass %.

Embodiment 3

[0159] Except having changed the quantity of MMM into 0 mass part from 0.06 mass part, it superposed|polymerized similarly to Example 2, and obtained the latex. The solid content concentration of the obtained latex was 20.0 mass %.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com