Production process of post-foaming cleansing gel

A face cleansing and gel technology, which is applied in the field of skin care products, can solve the problems of high irritation, insufficient user experience, and easy skin damage, and achieve the effect of reducing irritation, rich foam, and improving cleaning ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0070] Embodiment 1: Post-foaming cleansing gel, the components included and the parts by weight thereof are shown in Table 1, prepared through the following steps:

[0071] S1, mix pure water, hydroxyethyl cellulose, and D-sorbitol with each other, and stir for 20-30 minutes to form an aqueous phase mixture;

[0072] S2, pump the aqueous phase mixture obtained in step S1 into a synthesis pot, add triethanolamine, mix well, raise the temperature to 80-85°C and keep the temperature, then add palmitic acid, laureth-23, stearic acid , saponified for 60-70min to form a saponified mixture;

[0073] S3, subjecting the saponified mixture obtained in step S2 to vacuum defoaming treatment, cooling down to 40-45°C, adding alkyl polyglycosides and Aloe barbadensis leaf juice, and mixing evenly to form a semi-finished product;

[0074] S4, inspecting the semi-finished product obtained in step S3, raising the temperature of the qualified semi-finished product to 61° C. to form a hot semi-...

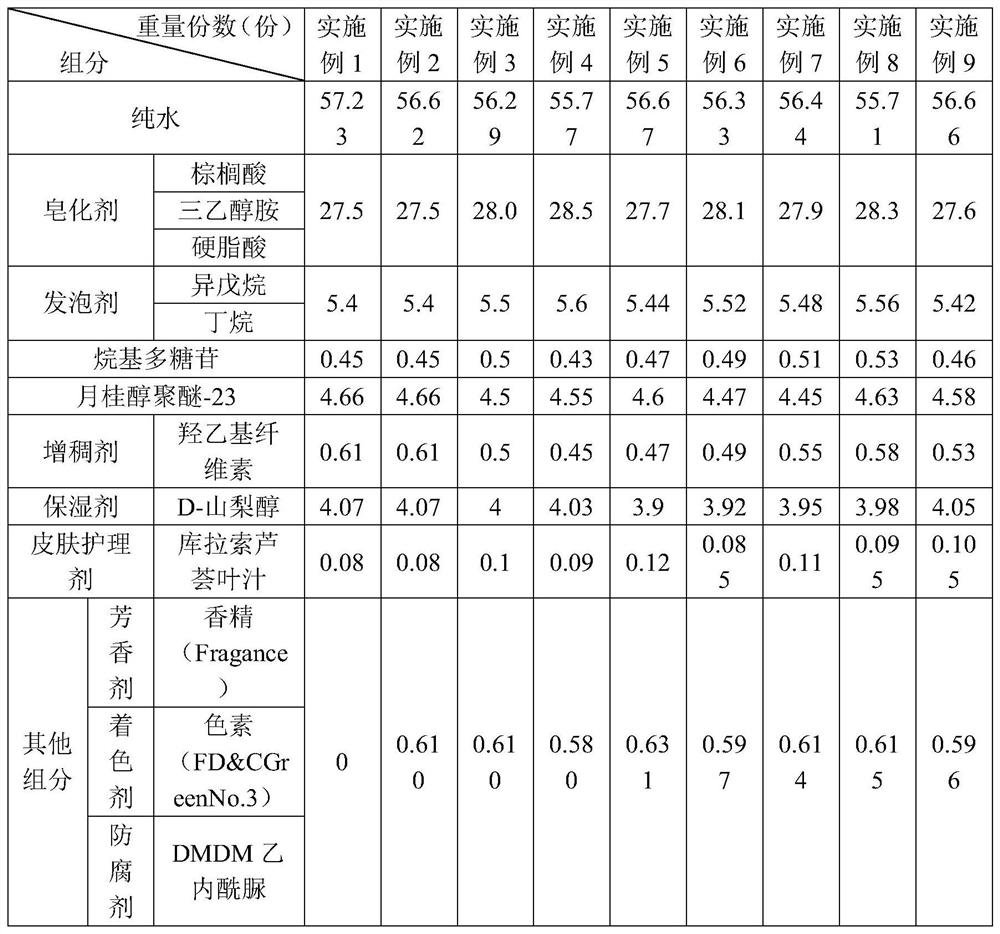

Embodiment 2-9

[0077] Embodiment 2-9: Post-foaming cleansing gel, the difference from Example 1 is that the included components and parts by weight are as shown in Table 1, and contain other components, wherein the ratio of parts by weight is 30: Fragrance, colorant, and preservative at a ratio of 1:30, where the fragrance is essence, the colorant is pigment, and the preservative is DMDM hydantoin.

[0078] Components and parts by weight thereof in Table 1 Embodiment 1-9

[0079]

Embodiment 10

[0080] Embodiment 10: post-foaming cleansing gel, the difference from embodiment 2 is that the ratio of parts by weight of saponifier to foaming agent is 5.10:1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com