A preparation method of bi-2223/agau superconducting tape with high current carrying and low thermal conductivity

A bi-2223, superconducting tape technology, applied in the use of superconducting elements, superconducting devices, superconducting/high-conducting conductors, etc. , low density of strip core wire, etc., to achieve the effect of low thermal conductivity, high current-carrying performance and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] This embodiment includes the following steps:

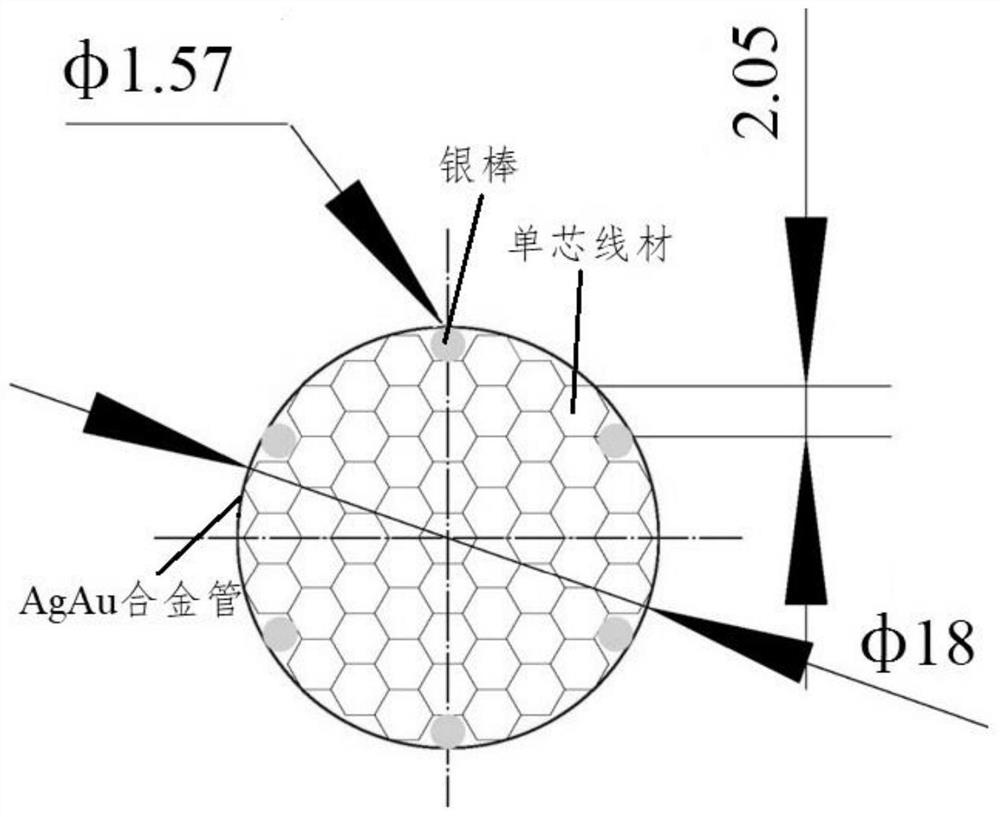

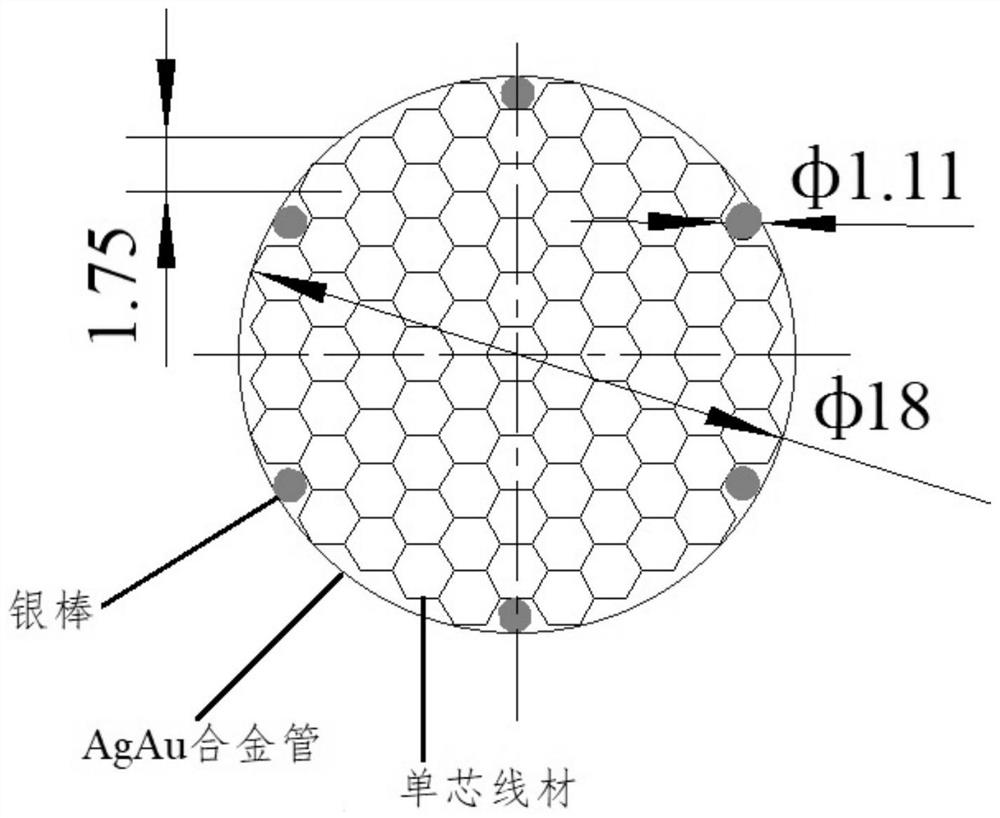

[0028]Step 1. In a glove box with an oxygen volume content of 7.5% and a balance gas of argon with a mass purity of 99.995%, a vibrating table is used to install a tube under the condition of a vibration frequency of 40 Hz, and the Bi-2223 precursor powder is passed through a metal funnel Fill the AgAu alloy tube with one end closed, and start the vibrating table to vibrate the AgAu alloy tube, so that the Bi-2223 precursor powder is filled into the AgAu alloy tube, and then the other end of the AgAu alloy tube is sealed to obtain the first tube. Composite; the Bi-2223 precursor powder contains Bi-2212 and CaCuO 2 , and Bi-2212 and CaCuO 2 The molar ratio of the AgAu alloy tube is 1:1, the outer diameter of the AgAu alloy tube is 12mm, the wall thickness is 1mm, and the mass content of the Au element in the AgAu alloy tube is 5%;

[0029] In step 2, the first tube-loading composite body obtained in step 1 is drawn with a...

Embodiment 2

[0034] This embodiment includes the following steps:

[0035] Step 1. In a glove box with an oxygen volume content of 7.5% and a balance gas of argon with a mass purity of 99.995%, a vibrating table is used to install a tube under the condition of a vibration frequency of 40 Hz, and the Bi-2223 precursor powder is passed through a metal funnel Fill the AgAu alloy tube with one end closed, and start the vibrating table to vibrate the AgAu alloy tube, so that the Bi-2223 precursor powder is filled into the AgAu alloy tube, and then the other end of the AgAu alloy tube is sealed to obtain the first tube. Composite; the Bi-2223 precursor powder contains Bi-2212 and CaCuO 2 , and Bi-2212 and CaCuO 2 The molar ratio of the AgAu alloy tube is 1:1, the outer diameter of the AgAu alloy tube is 12mm, the wall thickness is 1.1mm, and the mass content of the Au element in the AgAu alloy tube is 5%;

[0036] In step 2, the first tube-loading composite body obtained in step 1 is drawn wit...

Embodiment 3

[0041] This embodiment includes the following steps:

[0042] Step 1. In a glove box with an oxygen volume content of 7.5% and a balance gas of argon with a mass purity of 99.995%, a vibrating table is used to install a tube under the condition of a vibration frequency of 40 Hz, and the Bi-2223 precursor powder is passed through a metal funnel Fill the AgAu alloy tube with one end closed, and start the vibrating table to vibrate the AgAu alloy tube, so that the Bi-2223 precursor powder is filled into the AgAu alloy tube, and then the other end of the AgAu alloy tube is sealed to obtain the first tube. Composite; the Bi-2223 precursor powder contains Bi-2212 and CaCuO 2 , and Bi-2212 and CaCuO 2 The molar ratio of the AgAu alloy tube is 1:1, the outer diameter of the AgAu alloy tube is 12mm, the wall thickness is 1.5mm, and the mass content of the Au element in the AgAu alloy tube is 5%;

[0043] In step 2, the first tube-loading composite body obtained in step 1 is drawn wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com