Soapstock acidification wastewater treatment process

A wastewater treatment and soapstock technology, applied in water/sewage treatment, water treatment parameter control, water/sewage multi-stage treatment, etc., to achieve the effects of saving industrial water supply, reliable and continuous operation, and realizing the utilization of waste resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

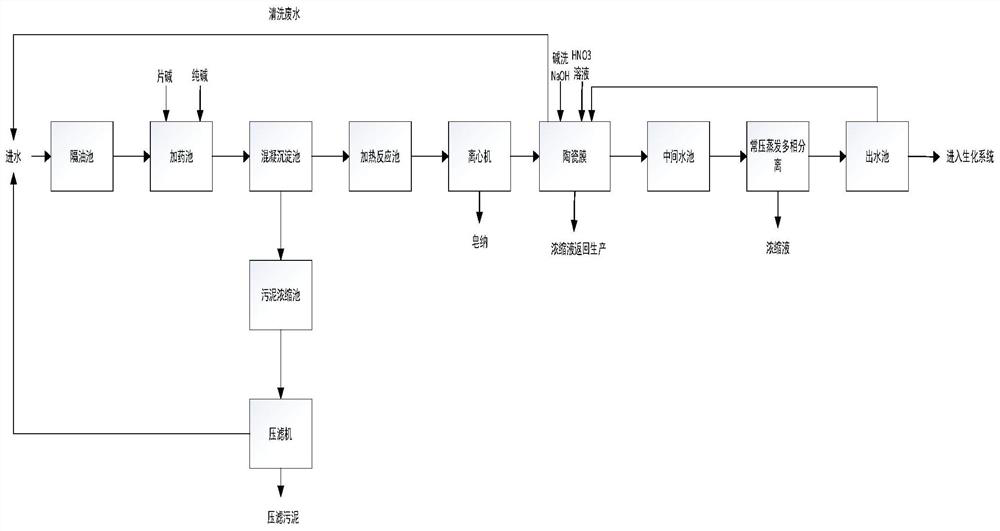

Method used

Image

Examples

Embodiment 1

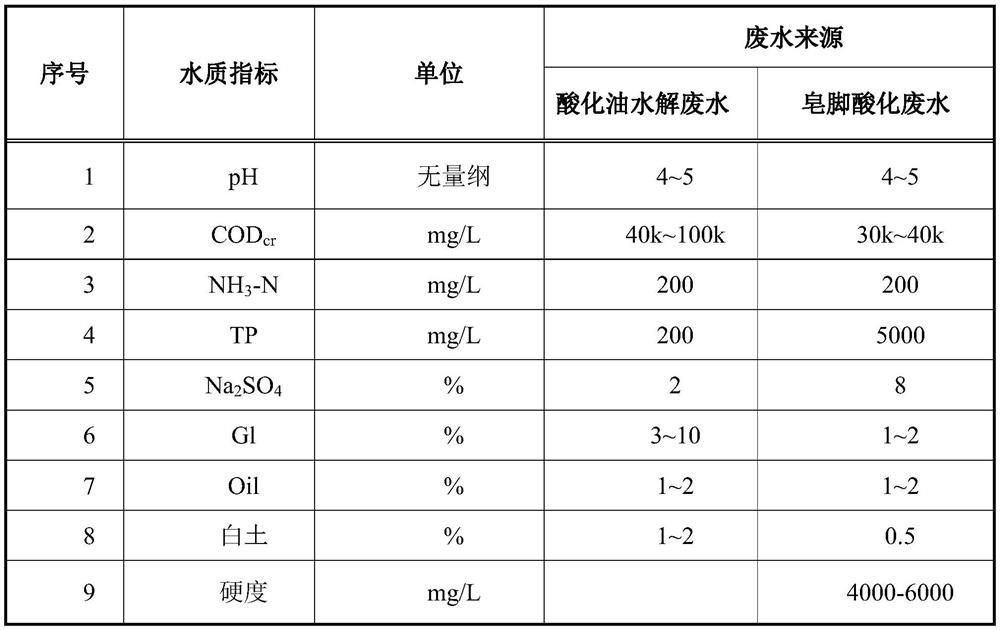

[0061] An oil company in Dalian is located in Songmu Island Chemical Industry Park. The company is a large-scale private enterprise mainly engaged in the production, processing and research and development of soybean oil chemical products. It is currently one of the professional acidified oil processing enterprises in China. Raw materials are processed and produced by advanced "fatty acid continuous vacuum distillation technology" to produce oleic acid, stearic acid and other chemical products, extending the industrial chain of oils and fats and realizing the recycling of waste resources. This process produces a large amount of acidified wastewater . The wastewater quality is shown in Table 1 as follows:

[0062] Waste Water Quality Index

[0063]

[0064] Table 1

[0065] 1. Dosing to remove hard flocculation and sedimentation process

[0066] The soapstock acidification wastewater enters the isolation tank. After the oil separation tank is degreased, the soapstock acid...

Embodiment 2

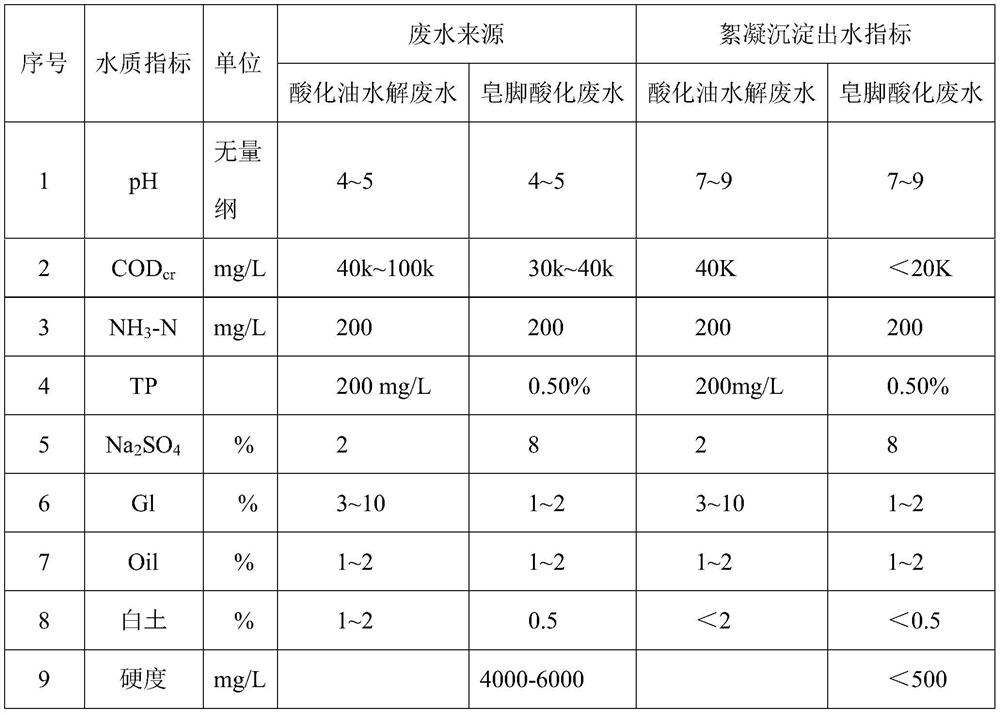

[0092] A company in Hebei that processes acidified oil produces a large amount of saponoid acidified wastewater in the production process, with a production volume of 30t / d.

[0093] 1. Adding medicine to remove hard flocculation and sedimentation process:

[0094] The soapstock acidification wastewater first enters the grease trap, after degreasing in the grease trap, it is pumped into the dosing pool by the pump, and the pH is adjusted to weak alkaline (7-8) by adding caustic soda, and then enters the coagulation by adding soda ash to remove the hardness Sedimentation tank for sedimentation, there will be a lot of impurities in the wastewater: hardness such as Ca 2+ , Mg 2+ , suspended solids, neutral oil, fatty acid, etc. enter the sedimentation; the sedimentation part is discharged into the sludge concentration tank, and the press filter sludge is obtained after press filtration through a filter press, which is handed over to a unit with hazardous waste disposal qualifica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com