Biological glue type seed coating agent, preparation method and use thereof

A technology of biological glue and disintegrant, which is applied in the fields of botanical equipment and methods, biocides, animal repellents, etc., can solve the problem that the seed treatment technology has not made breakthrough progress.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Example 1: The biological glue seed coating agent includes 50 grams of polyacrylamide, 100 grams of sodium starch glycolate, 2000 grams of calcium-based bentonite, 3000 grams of talcum powder, 200 grams of Artemisia annua gum, and 100 grams of carboxymethylcellulose.

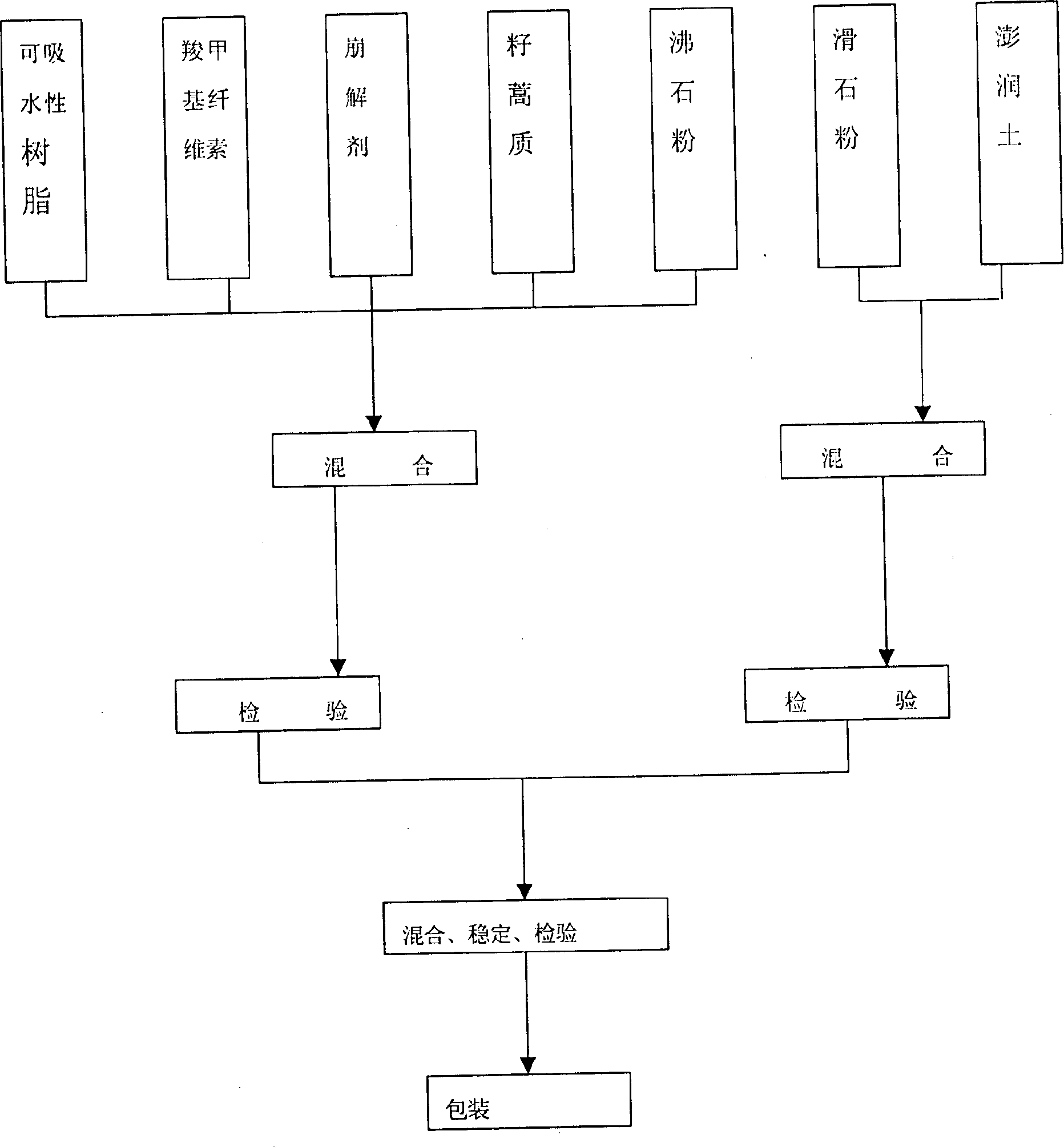

[0035] Its preparation method includes the following steps: its preparation process is carried out at normal temperature,

[0036] (1) Proportionally crush polyacrylamide, sodium carboxymethyl starch, seed artemisia gum and carboxymethyl cellulose with ultra-fine grinding equipment, filter and mix for more than 30 minutes, and check the fineness of the powder, which is required to reach 500 mesh above;

[0037] (2) Grinding, filtering and mixing the talcum powder and calcium-based bentonite with ultra-fine grinding equipment for more than 30 minutes in proportion, and checking the fineness of the powder, which is required to reach more than 500 mesh;

[0038] (3) Mix the two mixtures obtained in steps (1...

Embodiment 2

[0040] Embodiment 2: biological rubber seed coating agent includes polyacrylate 500 grams, sodium carboxymethyl cellulose 600 grams, sodium bentonite 5000 grams, talcum powder 7000 grams, seed artemisia gum 1500 grams, carboxymethyl cellulose 1000 grams , 800 grams of zeolite powder.

[0041] Its preparation method includes the following steps: its preparation process is carried out at normal temperature,

[0042] (1) Pulverize, filter and mix polyacrylate, sodium carboxymethyl cellulose, wormwood gum, carboxymethyl cellulose and zeolite powder with ultra-fine grinding equipment in proportion for more than 30 minutes, and check the fineness of the powder, It is required to reach more than 500 mesh;

[0043] (2) Grinding, filtering and mixing the talcum powder and calcium-based bentonite with ultra-fine grinding equipment for more than 30 minutes in proportion, and checking the fineness of the powder, which is required to reach more than 500 mesh;

[0044] (3) Mix the two mix...

Embodiment 3

[0046] Embodiment 3: biological glue seed coating agent includes polyvinyl alcohol 250 grams, sodium carboxymethyl cellulose and sodium carboxymethyl starch 350 grams, sodium-based bentonite and calcium-based bentonite 3500 grams, talcum powder 5000 grams, Artemisia sativa gum 850 grams, carboxymethyl cellulose 550 grams, zeolite powder 450 grams.

[0047] Its preparation method includes the following steps: its preparation process is carried out at normal temperature,

[0048] (1), polyvinyl alcohol, sodium carboxymethyl cellulose and sodium carboxymethyl starch, seed artemisia gum and

[0049] Carboxymethyl cellulose and zeolite powder are pulverized, filtered and mixed for more than 30 minutes with ultra-fine grinding equipment, and the fineness of the powder is inspected, which is required to reach more than 500 mesh;

[0050] (2) Grinding, filtering and mixing talc powder, calcium-based bentonite and sodium-based bentonite with ultra-fine grinding equipment in proportion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com