Sand blasting device for blade production

A sandblasting device and blade technology, which is applied to the used abrasive processing device, abrasive feeding device, abrasive jetting machine tool, etc. problems, to achieve the effect of improving kinetic energy, improving efficiency, and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

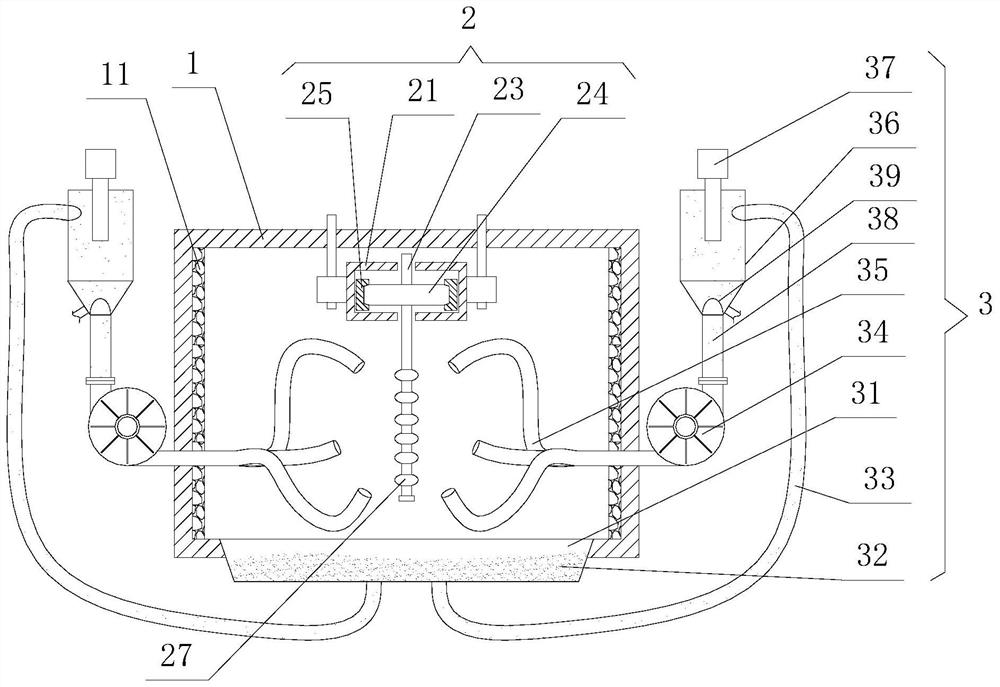

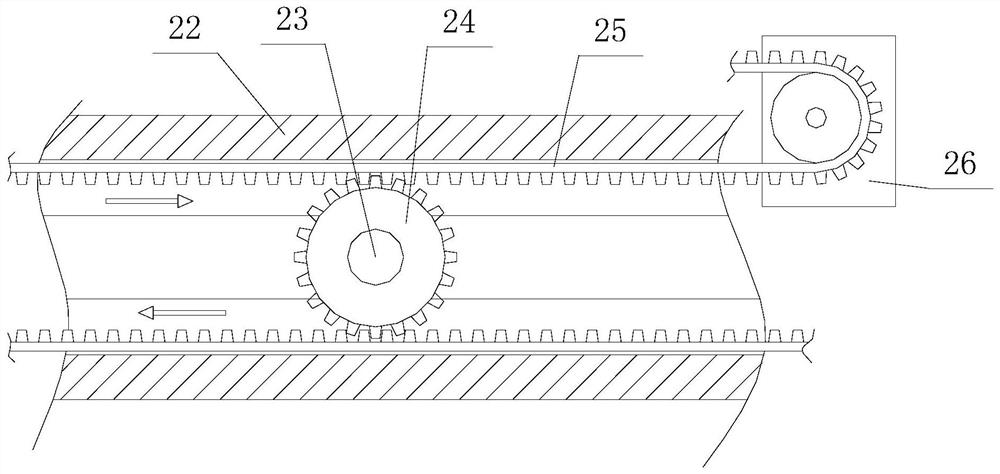

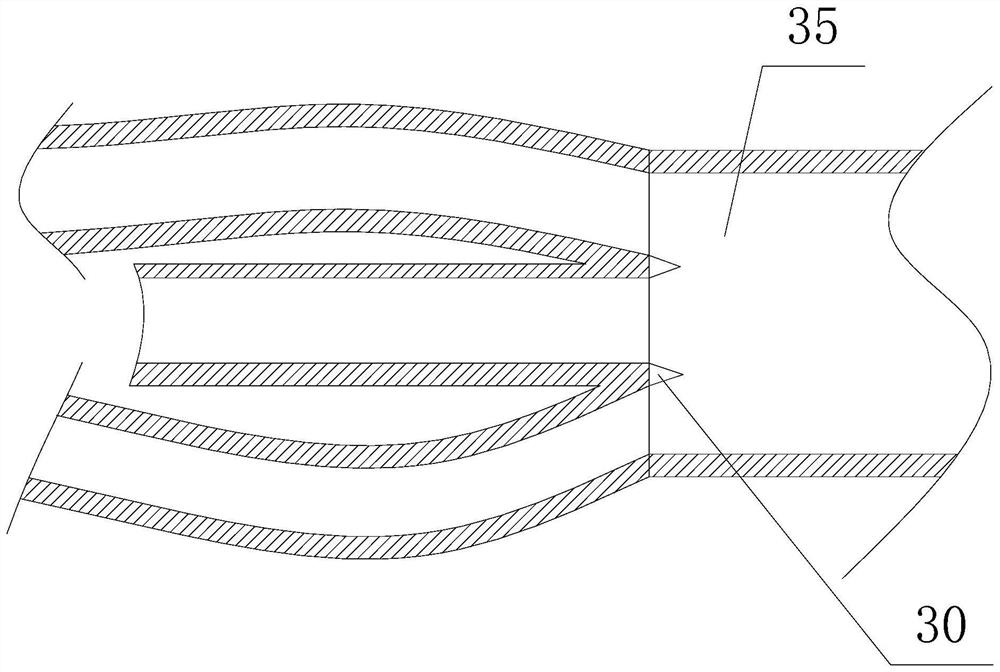

[0024] Such as Figure 1 ~ Figure 3 As shown, the sandblasting device for blade production provided in this embodiment includes a box body 1, a conveying mechanism 2, and a sandblasting mechanism 3. A sandblasting mechanism 3 is symmetrically installed on the top, and the inner wall of the box is provided with a detachable inner liner 11, and the conveying mechanism 2 includes a slide rail 21, a support rod 23, a gear 24, a timing belt 25 and a partition block 27, The slide rail 21 is horizontally installed on the upper part of the box body 1 along the length direction of the box body 1. The slide rail 21 is made by two C-shaped or U-shaped rails 22 openings that are relatively fastened, and there is a gap between the two rails 22. The gap for the passage of the support rod 23, the top of the support rod 23 is equipped with a gear 24 located in the track 22, and a synchronous belt 25 meshing with the gear 24 is installed in the two tracks 22, and the rotation direction of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com