Preparation and application of sodium alginate-based aerogel

A technology of sodium alginate and aerogel, which is applied in the field of biomass-based functional material preparation, can solve the problems of low toxicity of methylenebisacrylamide, inability to be used in the field of food processing, inability to carry out heavy metal adsorption, etc. Convenience, easy mass production and popularization, easy to control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

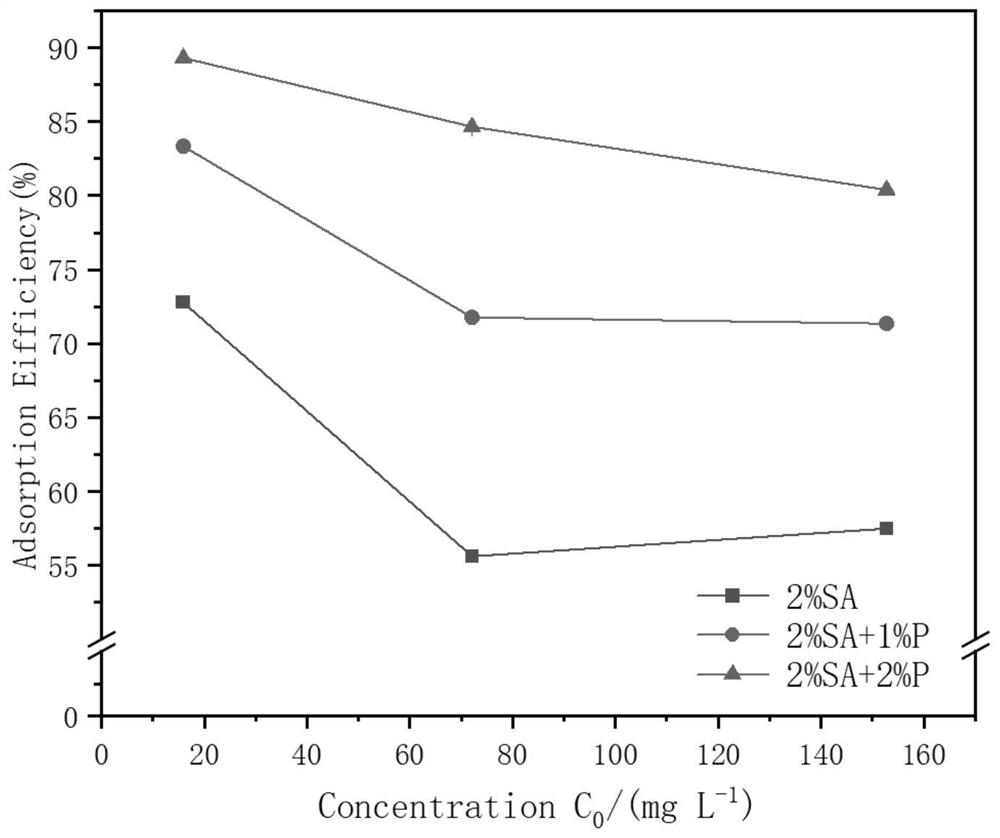

[0040] Determination of the removal rate of sodium alginate-based aerogels with different pectin contents This example tests the effect of sodium alginate-based aerogels with different pectin contents on the removal rate of Cd(II) ions in aqueous solution:

[0041] Prepare the following three solutions respectively:

[0042] 2% (w / v) sodium alginate in water.

[0043] 2% (w / v) sodium alginate + 1% (w / v) pectin in water.

[0044] 2% (w / v) sodium alginate + 2% (w / v) pectin in water.

[0045] The specific steps are as follows: weigh sodium alginate and pectin powder, mix them evenly, add them into deionized water to prepare a solution, stir them with a DC mixer equipped with paddle-type stirring paddles until uniform, and stand in a water bath at 25°C for 18 hours.

[0046] In this example,

[0047] The specific parameters of sodium alginate are: G / M<1, 815mPa·s, 80mesh.

[0048] The specific parameters of pectin are: degree of esterification 8.4%, gel strength 135.6, galacto...

Embodiment 2

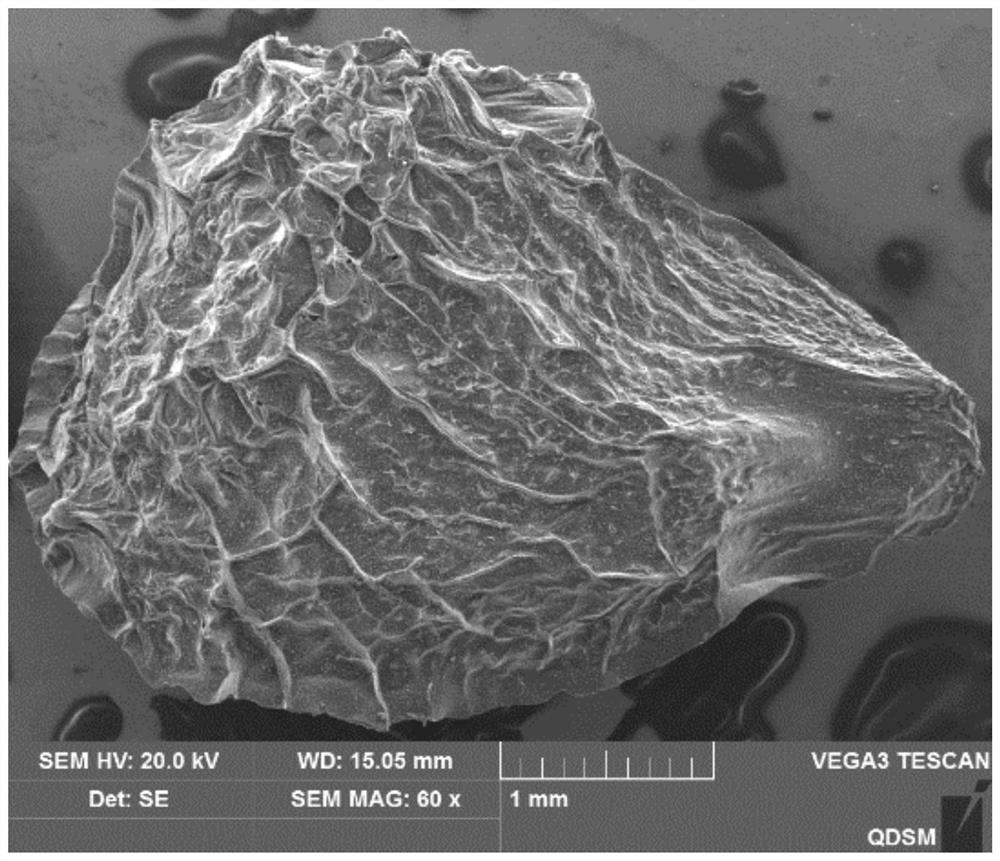

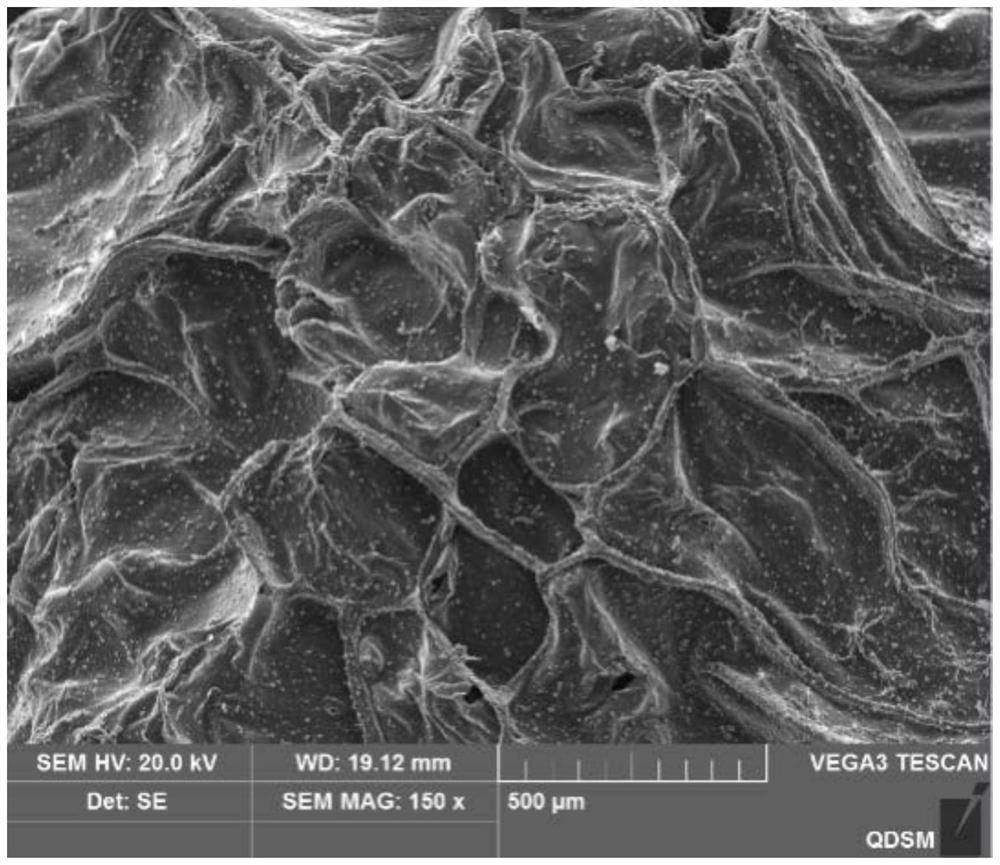

[0061] This example provides a sodium alginate-based airgel and its performance measurement.

[0062] The specific parameters of sodium alginate used are: G / M<1, 815mPa·s, 80mesh.

[0063] The specific parameters of pectin are: degree of esterification 8.4%, gel strength 135.6, galactose carboxylic acid 69.1%.

[0064] According to the method of the above-mentioned Example 1, configure 2% (w / v) sodium alginate+3% (w / v) pectin aqueous solution;

[0065] Stir with a DC mixer equipped with a paddle-type stirring paddle until uniform, and stand in a water bath at 25°C for 16h. A calcium lactate solution with a mass concentration of 1% (w / v) was prepared with deionized water.

[0066] Use a peristaltic pump to drip 2% (w / v) sodium alginate + 3% (w / v) pectin aqueous solution into the calcium lactate solution at an even speed, soak until the hydrogel beads are completely solidified, and separate the hydrogel beads. After rinsing the ball with deionized water, air-dry the water sta...

Embodiment 3

[0080] In order to improve the efficiency of cross-linking sodium alginate-pectin blending and cross-linking, in the preparation process of this embodiment, electric field treatment is added, and the sodium alginate-pectin aqueous solution prepared in step (1) and the calcium salt prepared in step (2) The aqueous solution is placed in an electrostatic electric field, the electric field voltage is 1.0-2.5KV, and the treatment time is 1-8h; after the electric field treatment is completed, proceed to step (3) gel granulation. After electric field treatment, the cross-linking of sodium alginate-pectin is more stable, the granulation effect is better, and the pelleting rate is higher. At present, at the laboratory stage, 3g of pectin and 2g of sodium alginate can prepare at least 3.92g of airgel material, and the dehydration rate during the preparation of airgel is as high as 95-98%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of esterification | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com