Hydrogen sensor for leakage detection and preparation method of sensitive element of hydrogen sensor

A technology for leak detection and sensitive components, which is applied in the field of hydrogen sensors, can solve problems such as the inability to achieve sensitivity in hydrogen detection, the limited application of high-precision leak detection technology, and the impossibility of hydrogen leak detection methods, so as to improve the hydrogen sensitivity response performance and improve Hydrogen sensitive properties, the effect of reducing microstructure fracture of thin film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

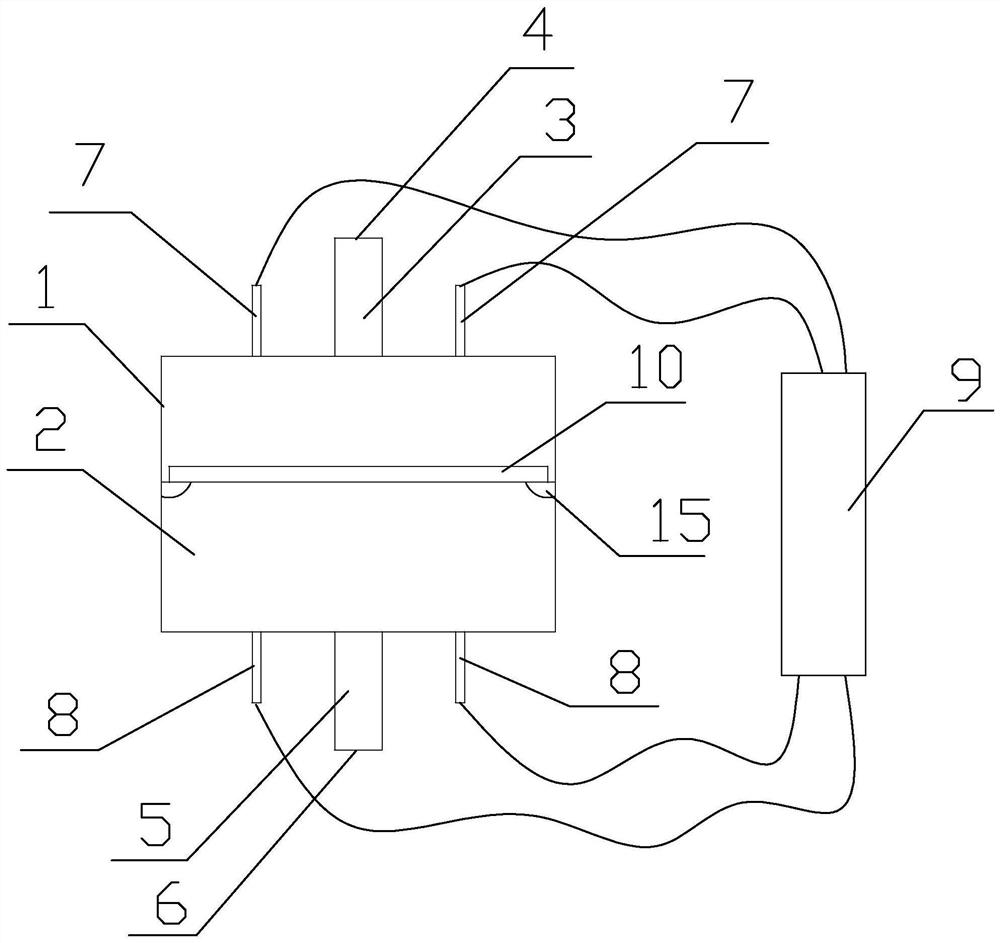

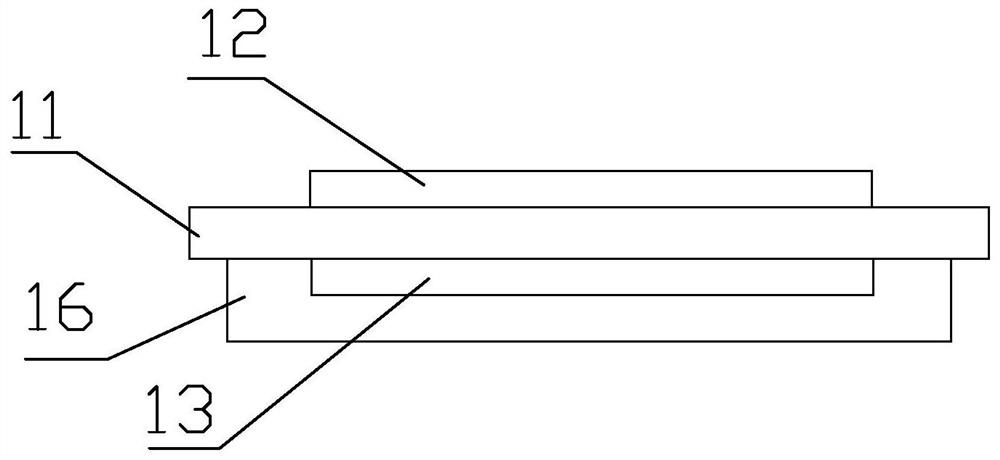

[0029] Embodiment: a kind of hydrogen sensor for leakage detection of the present embodiment, such as figure 1As shown, it includes a cylindrical casing 1, which encloses an air chamber 2, the diameter of the air chamber is less than 20mm, and the height of the air chamber is less than 10mm. The shell is made of stainless steel, with low adsorption rate and high temperature resistance. An air inlet pipe 3 communicating with the air chamber is installed at the center of the housing top to form an air inlet 4, and two measuring probes 7 are also installed on the housing top, and the two measuring probes are located on both sides of the air inlet pipe. An air outlet pipe 5 communicating with the air chamber is installed at the center of the housing bottom to form an air outlet 6, and two heating probes 8 are installed at the bottom of the housing, and the two heating probes are located on both sides of the air outlet pipe. The measuring probe and the heating probe are respective...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com