Double-pipe-rack slip form trolley and double-pipe-rack construction method

A mold trolley, trolley technology, applied in artificial islands, water conservancy projects, infrastructure engineering and other directions, can solve the problems of poor waterproof performance, high construction cost, poor molding quality, etc., to avoid material cutting, improve stability, Ease of construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

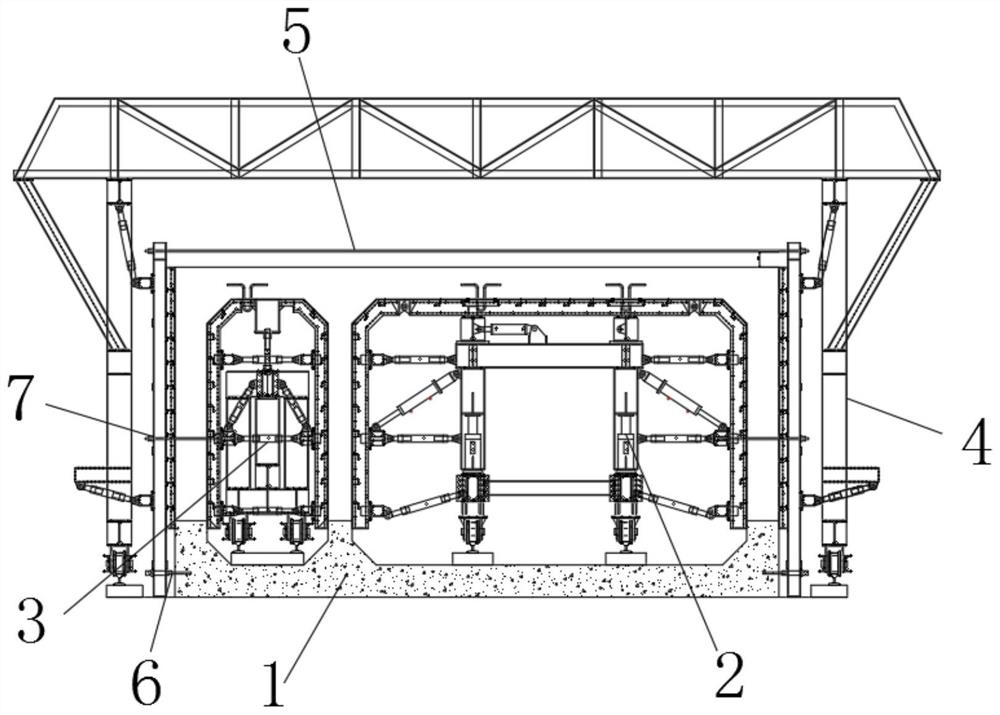

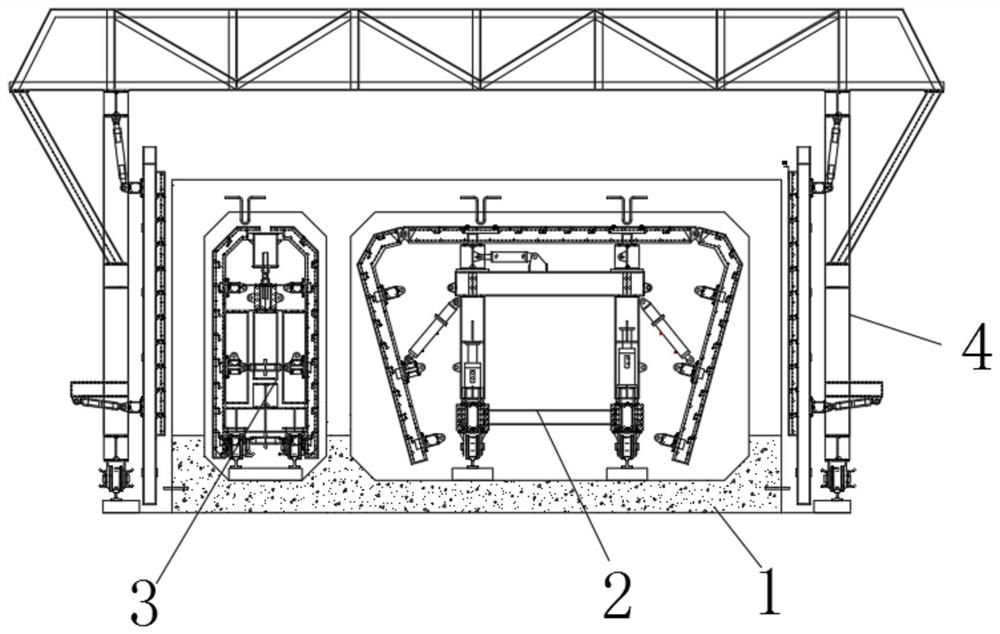

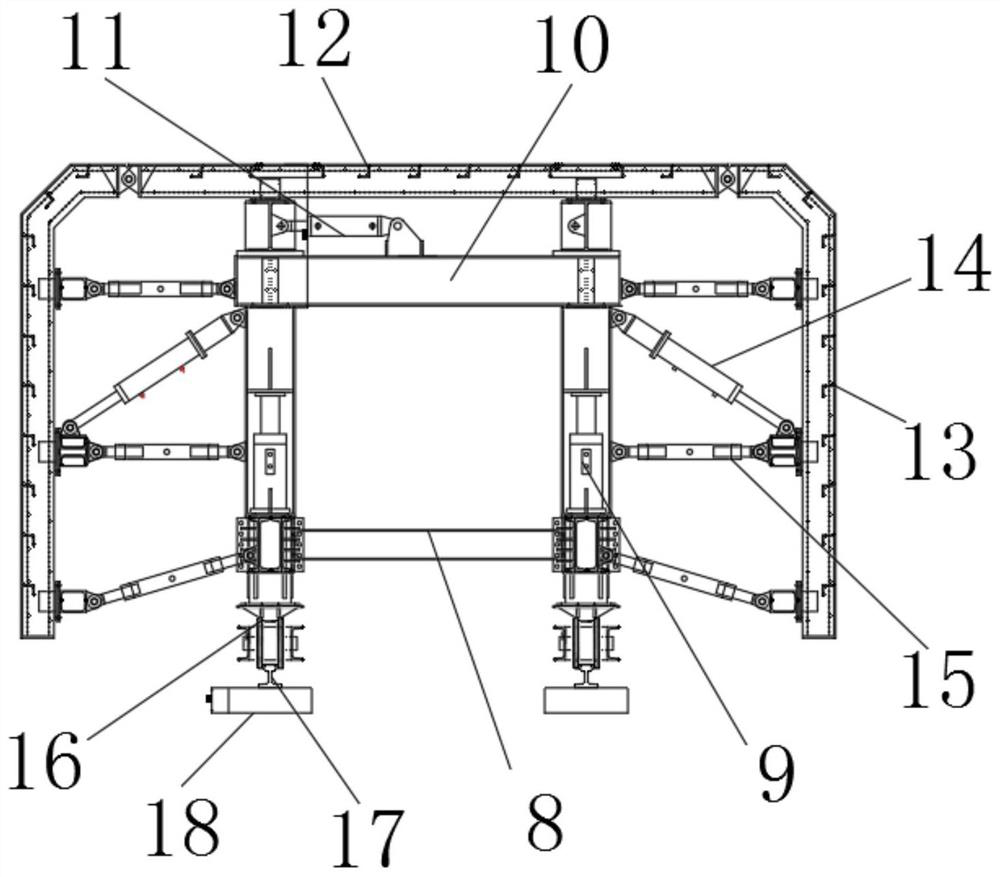

[0061] Example: Reference Figure 1-8 A sliding form trolley with double-pipe gallery shown includes a bottom plate 1, an inner mold trolley 2 is installed on the top of the bottom plate 1, and a gas cabin trolley 3 installed on the bottom plate 1 is arranged on one side of the inner mold trolley 2 , the outer mold trolley 4 is arranged on both sides of the bottom plate 1, the inner mold trolley 2 and the gas cabin trolley 3 are arranged inside the outer mold trolley 4, the outer mold trolley 4 is connected to the bottom plate 1 through a plurality of bottom tie rods 6, The outer mold trolley 4 is connected to the inner mold trolley 2 and the gas cabin trolley 3 through a plurality of tie rods 7 respectively, and a top tie rod 5 is installed in the outer mold trolley 4 .

[0062] With the above structure, the setting of the gas cabin trolley 3, the outer mold trolley 4 and the outer mold trolley 4 can enclose the pouring cavity of M structure, so that the pipe gallery can be p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com