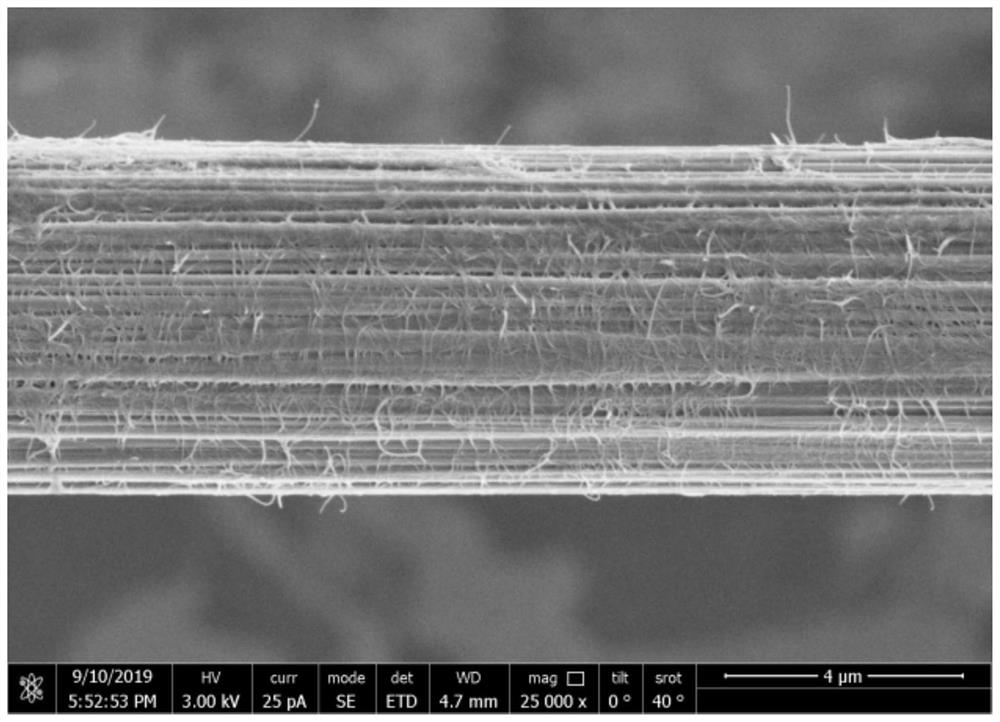

Preparation method of nano cellulose and carbon nanotube synergistically modified carbon fiber

A technology of nanocellulose and carbon nanotubes, which is applied in the fields of carbon fiber, fiber treatment, textiles and papermaking, etc., can solve the problem that the vacuum filtration method has not been applied to surface modification, etc., and achieves the advantages of interface stress transfer, simple equipment, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] This embodiment provides a method for preparing carbon fibers synergistically modified by nanocellulose and carbon nanotubes, which specifically includes the following steps:

[0026] 1) Freeze-drying the aqueous dispersion of cellulose nanofibers to obtain cellulose nanofibers for future use.

[0027] 2) Prepare an aqueous solution of cellulose nanofibers and carbon nanotubes with a mass fraction of 0.05% uniformly dispersed, respectively.

[0028] 3) The long carbon fiber tow was placed in an acetone solution at 80°C for condensing and refluxing for 24 hours, the extracted carbon fibers were cleaned with deionized water, and dried in a vacuum drying oven at 50°C for 3 hours.

[0029] 4) Mix the cellulose nanofiber aqueous solution and the carbon nanotube aqueous solution at a mass ratio of 1:1, and stir magnetically at 300 rpm / min for 30 minutes to disperse the solution evenly to obtain a mixed solution of cellulose nanofiber and carbon nanotube; process step 3) to ob...

Embodiment 2

[0032] This embodiment provides a method for preparing carbon fibers synergistically modified by nanocellulose and carbon nanotubes, which specifically includes the following steps:

[0033] 1) Freeze-drying the aqueous dispersion of cellulose nanofibers to obtain cellulose nanofibers for future use.

[0034] 2) Prepare an aqueous solution of cellulose nanofibers and carbon nanotubes with a mass fraction of 0.05% uniformly dispersed, respectively.

[0035] 3) The long carbon fiber tow was placed in an acetone solution at 100°C for condensing and refluxing for 12 hours, the extracted carbon fibers were cleaned with deionized water, and dried in a vacuum oven at 40°C for 5 hours.

[0036] 4) Mix the cellulose nanofiber aqueous solution and the carbon nanotube aqueous solution at a mass ratio of 1:1, stir the solution with a magnetic force at 500 rpm / min for 30 minutes to disperse the solution evenly, and obtain a mixed solution of cellulose nanofiber and carbon nanotube; process...

Embodiment 3

[0039] This embodiment provides a method for preparing carbon fibers synergistically modified by nanocellulose and carbon nanotubes, which specifically includes the following steps:

[0040] 1) Freeze-drying the aqueous dispersion of cellulose nanocrystals to obtain cellulose nanocrystals for future use.

[0041] 2) Prepare the cellulose nanocrystal aqueous solution and the carbon nanotube aqueous solution with a mass fraction of 2% and uniformly dispersed, respectively.

[0042] 3) The long carbon fiber tow was placed in an acetone solution at 80°C for condensing and reflux for 48 hours, the extracted carbon fibers were cleaned with deionized water, and dried in a vacuum oven at 70°C for 3 hours.

[0043]4) The carbon fiber tow obtained in step 3) is evenly placed on the filter membrane, and the cellulose nanocrystal is vacuumed on its surface according to the volume of the cellulose nanocrystal aqueous solution (ml): filter membrane diameter (cm)=0.2:1 The aqueous solution ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com