Method for preparing D-alanine by microbial fermentation method

A technology of Corynebacterium alanine and glutamic acid, applied in the field of microbial fermentation, can solve the problems of high price of substrate keto acid, restricting application, etc., and achieve the effects of low cost and simple technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

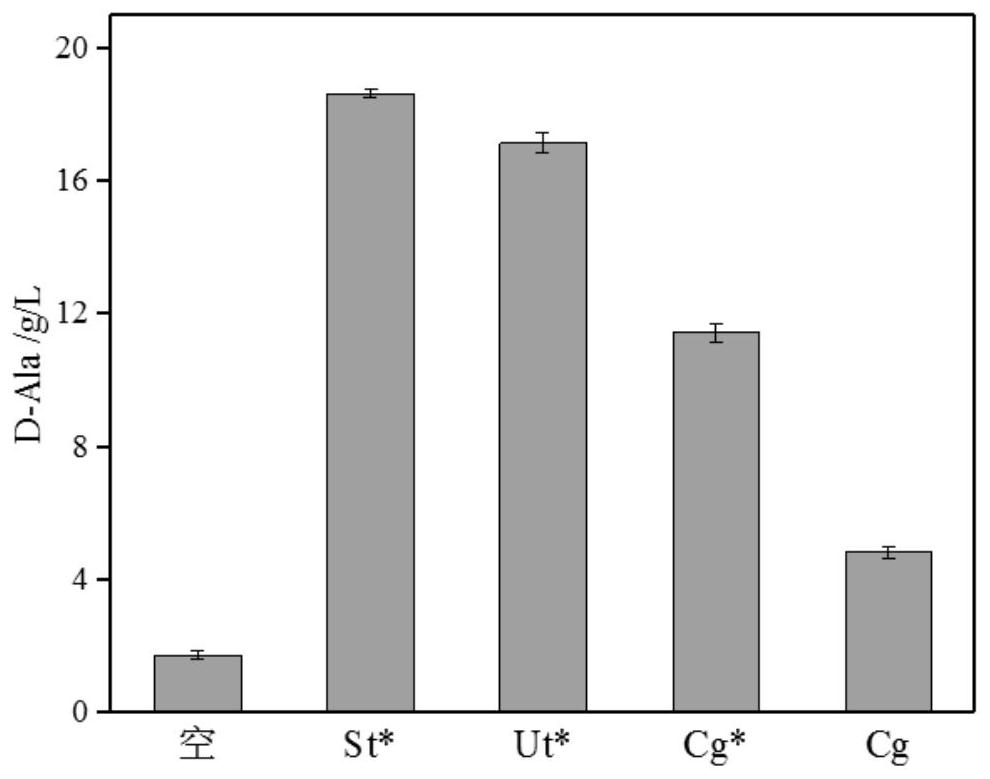

[0036] Example 1 Screening of D-amino acid tolerant strains

[0037] Four strains were selected from the three commonly used industrial fermentation strains of Bacillus subtilis, Escherichia coli and Corynebacterium glutamicum, specifically: Bacillus subtilis 168, E. coli BL21, E. coli (E. coli) W3110, Corynebacterium glutamicum (C. glutamicum) ATCC 13032.

[0038] Inoculate the four strains on gradient plates containing D-alanine respectively, draw a line from low concentration to high concentration (0-50g / L), and observe the growth after 24h as follows: figure 1 (a). After that, the highest tolerated concentration was investigated, and the shake tube culture was carried out with CGXII basic medium, and the concentration of D-alanine was set to 1g / L, 5g / L, 10g / L, 20g / L, and 50g respectively. / L, 100g / L, 24h results such as figure 1 (b).

[0039] According to the gradient plate display, the tolerance concentration of Bacillus subtilis to D-alanine is about 8g / L, the tolera...

Embodiment 2

[0040] Example 2 D-alanine production strain construction

[0041] Using C.glutamicum ATCC 13032 as the starting bacteria, rpsL K43R The point mutation made the strain resistant to streptomycin, and the suicide plasmid pK18mobrpsL was used (for the construction method, see: An update of the suicide plasma-mediated genome editing system in Corynebacterium glutamicum[J]. Microbial Biotechnology, 2019, 12(5): 907-919 .) mediated genome editing system of Corynebacterium glutamicum for genome editing.

[0042] (1) Firstly, the alanine racemase gene alr is knocked out on the genome, and the upper and lower homology arms of the knockout gene alr are subjected to homologous recombination with the double-digestion (XbaI and KpnI) vector of pK18mobrpsL to obtain pK18rpsL -The Δalr plasmid was electrotransformed into the competent state of the starting bacteria, and the double crossover was identified by primers alr-jd-1 and alr-jd-2, and strain S-1 was obtained;

[0043] (2) Continue ...

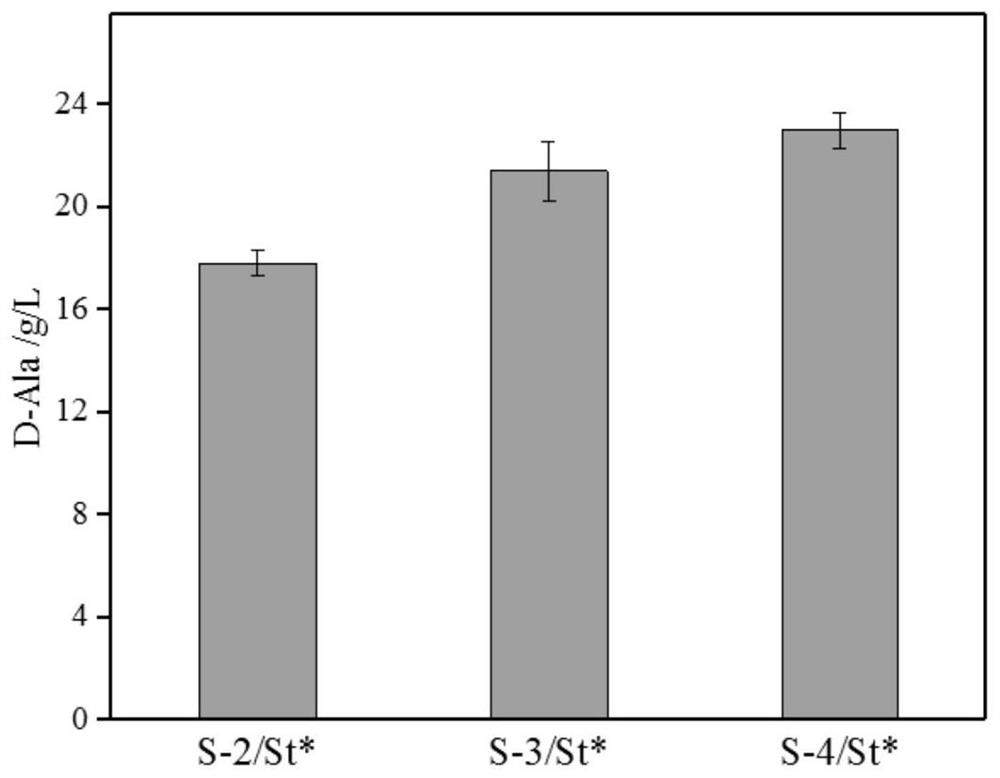

Embodiment 35

[0056] Example 3 Preparation of D-alanine by 5L tank fermentation method

[0057] Using the S-4 / pXtuf-St* prepared in Example 2 as the production strain to ferment and produce D-alanine:

[0058] Put the activated strain of the second-generation eggplant bottle into a fermenter equipped with seed medium, and cultivate it at 32°C until the OD is about 30, leaving 600mL of seed liquid, adding 20% of the inoculum to the fermentation medium, and continuing to It is fermented and cultivated under the conditions of pH6.7-7.2, temperature 32-34°C, and dissolved oxygen 10-40%. After 36 hours of fermentation, the yield reaches 50g / L.

[0059] Among them, the formula of D-alanine upper tank culture medium is as follows:

[0060] The composition of the seed medium is: glucose 60g / L, KH 2 PO 4 3g / L, MgSO 4 ·7H 2 O 2g / L, MnSO 4 ·H 2 O20mg / L, FeSO 4 20mg / L, V B1 0.5mg / L, VH 0.1mg / L, yeast powder 7g / L, methionine 0.5g / L, corn steep liquor 30g / L, soybean meal hydrolyzate 20-30mL...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tolerance concentration | aaaaa | aaaaa |

| Tolerance concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com