Titanate lamellar crystal rubber material for tires and preparation method of titanate lamellar crystal rubber material

A technology of titanate sheets and rubber materials, which can be used in special tires, tire parts, building insulation materials, etc., and can solve environmental pollution and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The invention provides a technical solution: a titanate plate crystal rubber material for tires, which is composed of the following materials in parts by weight: 90 parts by mass of natural rubber, 1 part by mass of antioxidant, 5 parts by mass of accelerator, zinc oxide 1.7 parts by mass, 5 parts by mass of copper inhibitor, 8 parts by mass of talc, 10 parts by mass of carbon black, 20 parts by mass of pine tar, and 15 parts by mass of titanate platelets.

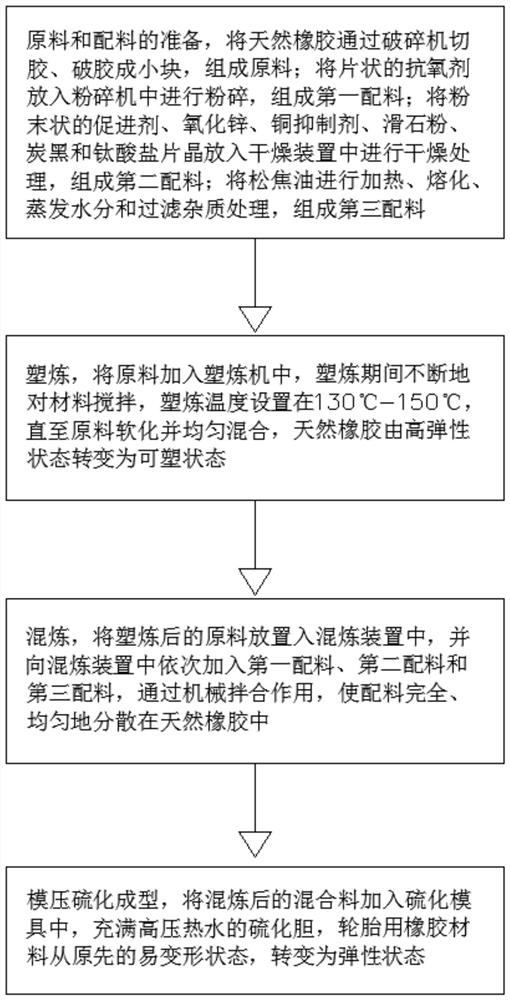

[0040] A preparation method of a titanate plate crystal rubber material for tires, comprising the following steps:

[0041] Step 1. Preparation of raw materials and ingredients. Natural rubber is cut and broken into small pieces by a crusher to form raw materials; the flake antioxidant is put into a crusher for crushing to form the first ingredient; The accelerator, zinc oxide, copper inhibitor, talcum powder, carbon black and titanate platelets are put into the drying device for drying treatment to form the second ...

Embodiment 2

[0046] The invention provides a technical solution: a titanate lamella rubber material for tires, which is composed of the following materials in parts by weight: 92 parts by mass of natural rubber, 2 parts by mass of antioxidant, 6 parts by mass of accelerator, zinc oxide 1.8 parts by mass, copper inhibitor 6 parts by mass, talc powder 9 parts by mass, carbon black 11 parts by mass, pine tar 21 parts by mass, and titanate lamellae 16 parts by mass.

[0047] A preparation method of a titanate plate crystal rubber material for tires, comprising the following steps:

[0048] Step 1. Preparation of raw materials and ingredients. Natural rubber is cut and broken into small pieces by a crusher to form raw materials; the flake antioxidant is put into a crusher for crushing to form the first ingredient; The accelerator, zinc oxide, copper inhibitor, talcum powder, carbon black and titanate platelets are put into the drying device for drying treatment to form the second ingredient; th...

Embodiment 3

[0053] The present invention provides a technical solution: a titanate lamellar rubber material for tires, which is composed of the following materials in parts by weight: 93 parts by mass of natural rubber, 3 parts by mass of antioxidant, 7 parts by mass of accelerator, zinc oxide 1.9 parts by mass, 7 parts by mass of copper inhibitor, 10 parts by mass of talc, 12 parts by mass of carbon black, 22 parts by mass of pine tar, and 17 parts by mass of titanate platelets.

[0054] A preparation method of a titanate plate crystal rubber material for tires, comprising the following steps:

[0055] Step 1. Preparation of raw materials and ingredients. Natural rubber is cut and broken into small pieces by a crusher to form raw materials; the flake antioxidant is put into a crusher for crushing to form the first ingredient; The accelerator, zinc oxide, copper inhibitor, talcum powder, carbon black and titanate platelets are put into the drying device for drying treatment to form the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com