LTCC ceramic material as well as preparation method and application thereof

A technology of ceramic materials and porcelain powder, which is applied in the field of LTCC ceramic materials and its preparation, can solve the problems of porous, poor temperature resistance of organic polymers, and the low temperature can only reach 0.11%, so as to improve the sintering density, ultra-low Dielectric constant, the effect of reducing the dielectric constant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0037] 1. Weigh raw materials according to the ratio: SiO 2 (56.9wt%), H 3 BO 3 (41.1wt%), K 2 CO 3 (1.5wt%), Na 2 CO 3 (0.1wt%), CaCO 3 (0.2wt%), BaCO 3 (0.2 wt%). Using an agate ball mill tank, using deionized water as a medium, planetary ball milling for 4 hours, discharging, drying at 100°C for 12 hours, to obtain raw material powder;

[0038] 2. Put the dried raw material powder in a platinum crucible, place it in a high-temperature furnace, and keep it warm at 1300°C for 2 hours to homogenize the glass liquid, take out the glass liquid at high temperature, and quench it in deionized water;

[0039] 3. Put the above-mentioned quenched glass in an agate ball mill jar, use zirconia balls as the medium, deionized water as the medium, and planetary ball mill for 12 hours to obtain glass slurry, and dry the glass slurry at 100°C for 12 hours to obtain K-B-Si (KBS) glass powder;

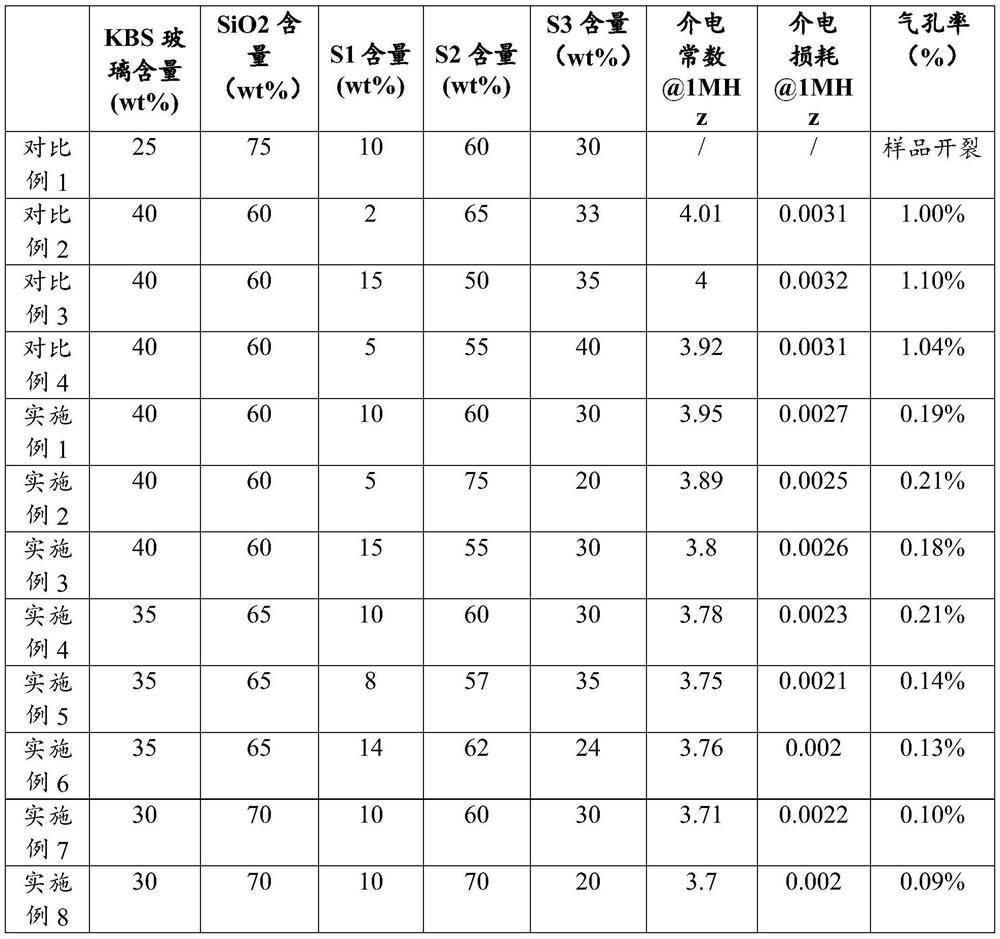

[0040] 4. Weigh KBS glass powder and spherical SiO with the ratio shown in Table 1 2 , ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dielectric loss | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com