Novel Portland cement production method

A Portland cement and production method technology, applied in the field of cement production, can solve the problems of environmental damage, resource concentration, etc., and achieve the effects of reducing smoke and dust, improving performance quality, and increasing heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

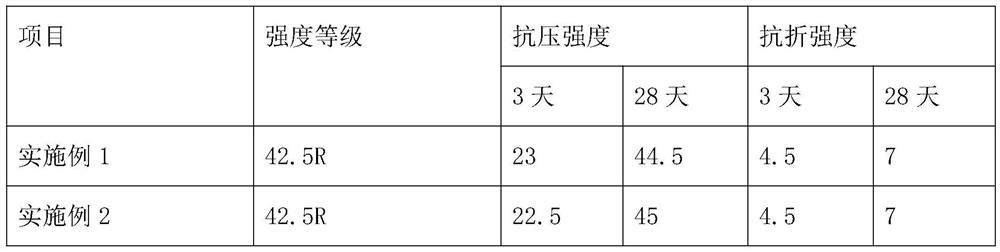

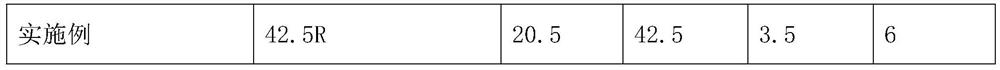

Examples

Embodiment 1

[0026] In the embodiment of the present invention, a new silicate cement comprising a weight of 56 limestone, 5 of acidic volcanic lava, 6 additional raw materials, and 7 mineralizers.

[0027] Further, the auxiliary raw material is blended by burning shale, pumice, volcanic, and gray grinding. Burning shale, pumice, volcanic, and coatite ratio is 2: 1: 1: 1.

[0028] Further, the mineralization agent uses a combination of plaster and fluorite, and the ratio is 1: 2.

[0029] Further, acidic volcanic lava uses fluidized condiments, zeolite rocks, black Yaosi, perlite, loose rock, acidic volcanic lava chemical composition comprises: silica about 69% -72%, trioxide Aluminum is about 12% -13.5%, and the three iron hydraulines is about 0.8% -1.2%, calcium oxide is about 0.8-1.5%, and the acid volcanic lava contains 2% -8%, and each cubic millimeter contains hundreds of water. The parts are firmly bonded, in a melting state of 1000 ° C -1200 ° C, the water is rapidly vaporized, and the...

Embodiment 2

[0045] Preparation is performed in accordance with the method of the examples, and is different from the first embodiment, including the following weights: 88 limestone, 12 of the acidic volcanic lava, 9 additional raw materials, 5 mineralizers.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com