Metal parts embedding equipment for plastic products production

A technology for plastic products and metal parts, which is applied in the field of metal parts embedded equipment for plastic products production, which can solve the problems of unstable connection, easy damage and disconnection, and inability to achieve wrapping processing and molding, so as to facilitate popularization and use , Improve the connection strength and improve the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

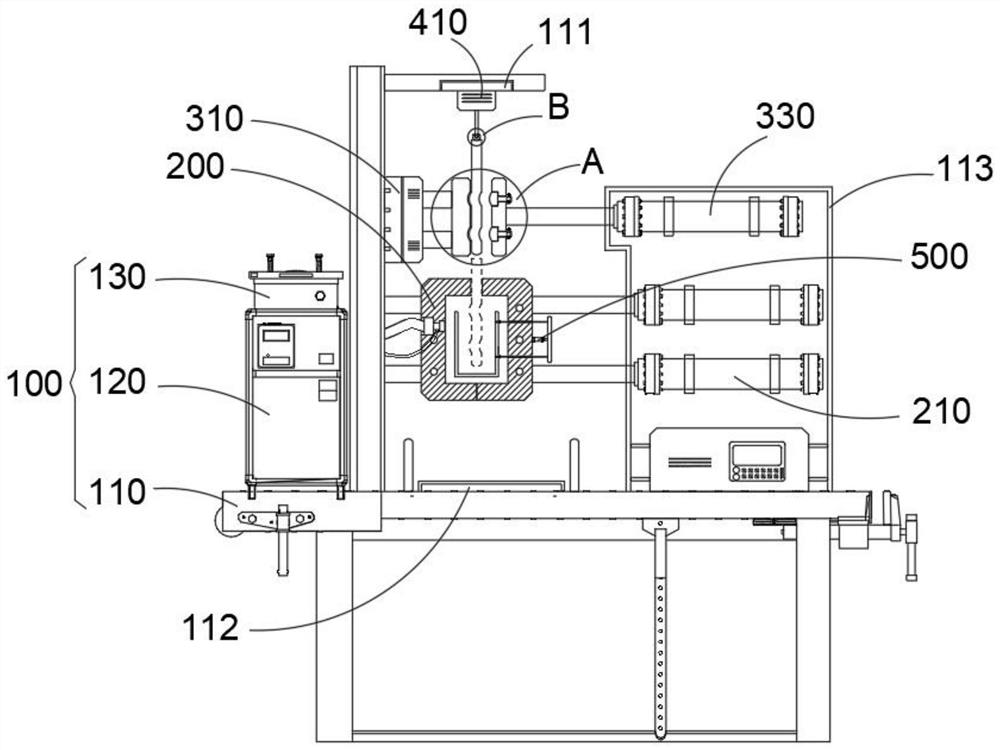

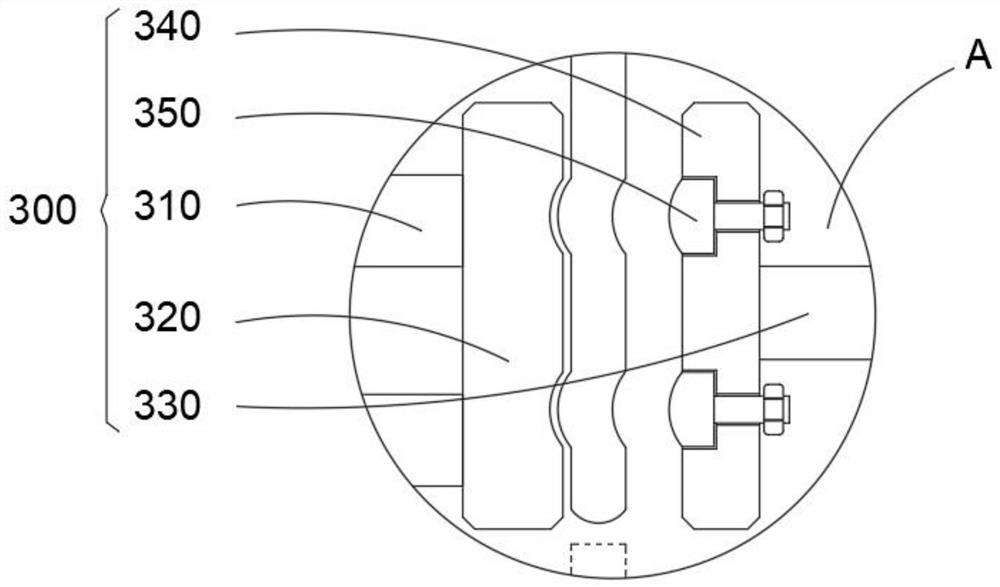

[0042] combine Figure 1-6As shown, the metal parts embedding equipment for the production of plastic products provided by the present invention includes: an injection molding mechanism 100, a molding mechanism 200, a molding mechanism 300 and a feeding mechanism 400, and the injection molding mechanism 100 includes a body 110, an injection molding machine for injection molding operations 120 and a cooling machine 130 for cooling operations. The body 110 is composed of a workbench and a mounting frame for the installation of operating parts as required, and the side of the workbench is provided with an adjustment assembly, which can adjust the position of the drive components on the mounting frame and the workbench. adjustment, the practicability is higher, and simultaneously the body 110 is provided with a control box 113 for hydraulic cylinder one 210 and hydraulic cylinder two 330 to be installed, and the front of the control box 113 is provided with a control panel for hydr...

Embodiment 2

[0047] combine Figure 5 As shown, on the basis of the first embodiment, the mouth changing mechanism 600 is installed on the molding mechanism 200, which is convenient for sealing and fixing metal parts of different sizes. The mouth changing mechanism 600 can clamp the movable mold 220 and the top of the fixed mold 230 The opening 620 is replaced, and the clamping opening 620 is an opening for clamping metal parts. After replacement, it can be adapted to use with metal parts of different sizes, and the practicability is higher.

[0048] Specifically, the mouth changing mechanism 600 includes a connecting plate 610 installed on the top of the movable mold 220 and the fixed mold 230, a clamping opening 620 opened on the connecting plate 610 and adapted to the metal parts, and connected to the side of the connecting plate 610 and threaded. On the fixed side 630 on the movable mold 220, the connecting plate 610 is attached to the movable mold 220 and the fixed mold 230. Like the ...

Embodiment 3

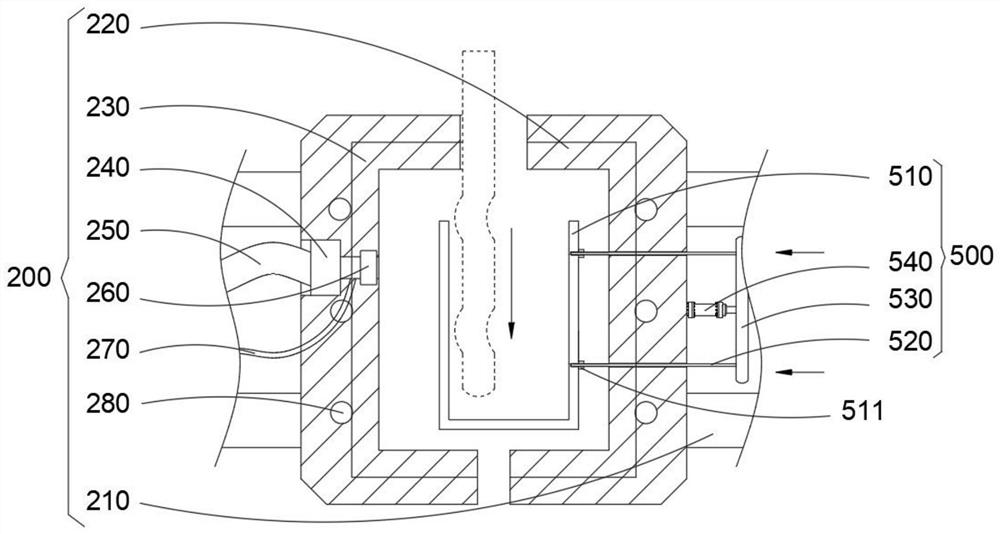

[0051] combine figure 2 As shown, in the above-mentioned embodiment, the positioning mechanism 500 is installed on the movable mold 220, and is used to embed the built-in metal parts before injection molding. Through the positioning mechanism 500, the built-in parts 510 can be put into the movable mold 220 and the fixed mold 230 to realize Fully embedded metal parts can improve the structural strength of metal-plastic molded parts, prevent plastic parts from being damaged after long-term use, and thus increase the service life of finished products.

[0052] Specifically, the positioning mechanism 500 includes a built-in part 510 arranged between the movable mold 220 and the fixed mold 230, an insertion rod 520 inserted through the movable mold 220 to position the built-in part 510, a mounting plate 530 connected to the outer end of the insertion rod 520, The electric push rod 540 connected to the mounting plate 530 for driving the insertion rod 520, the built-in part 510 can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com