Composite lawn maintenance method

A compound and lawn technology, applied in lawn growth, botany equipment and methods, gardening, etc., can solve the problems of reducing maintenance effect, nodules not combing, adjusting comb teeth, etc., to improve maintenance effect and improve functionality , the effect of improving applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

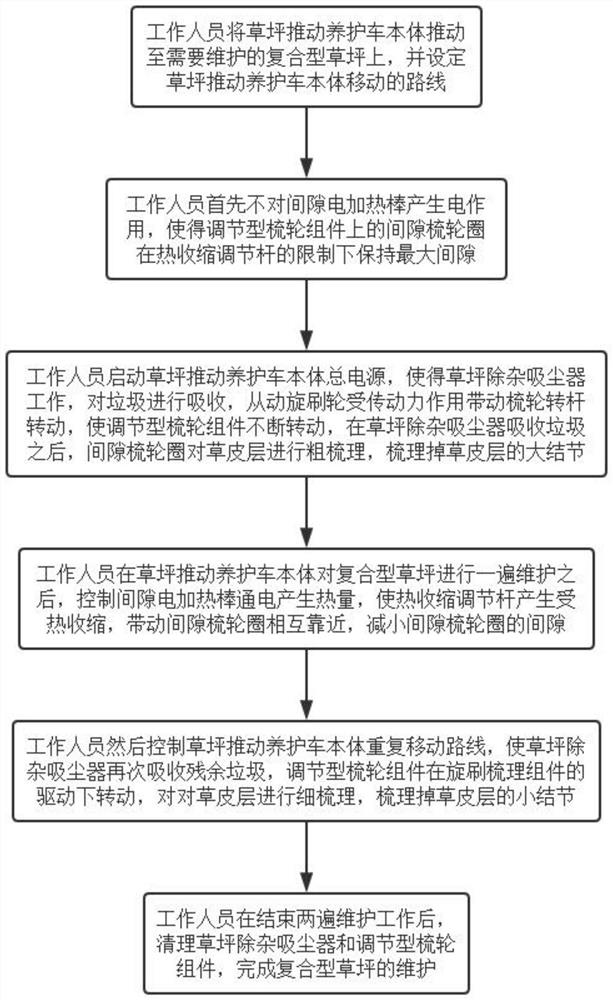

[0049] See Figure 1-8 A composite turf maintenance method, comprising the steps of:

[0050] . S1 staff will push lawn maintenance vehicle body 1 to promote the complex lawn maintenance needs, and set the push lawn maintenance vehicle body 1 moving route;

[0051] . S2 staff first gap electric heating rods 601 does not generate an electric effect, such that the regulating gap type comb wheel assembly rim 4 of the comb gap 401 remains at the maximum heat shrinkage limit adjusting lever 6;

[0052] S3. Staff starts pushing a main power lawn maintenance vehicle body, so that the lawn work impurity cleaner 2, the absorption of the garbage, the driven wheel rotating brush 302 driven by the drive force acting comb rotary lever 303 is rotated, the adjustment comb-type wheel assembly 4 is rotated continuously, after impurity absorption lawn refuse vacuum cleaner, the rim 401 of crude comb gap turf layer carded, combed out the greater tuberosity of divots;

[0053] S4. After staff promote ...

Embodiment 2

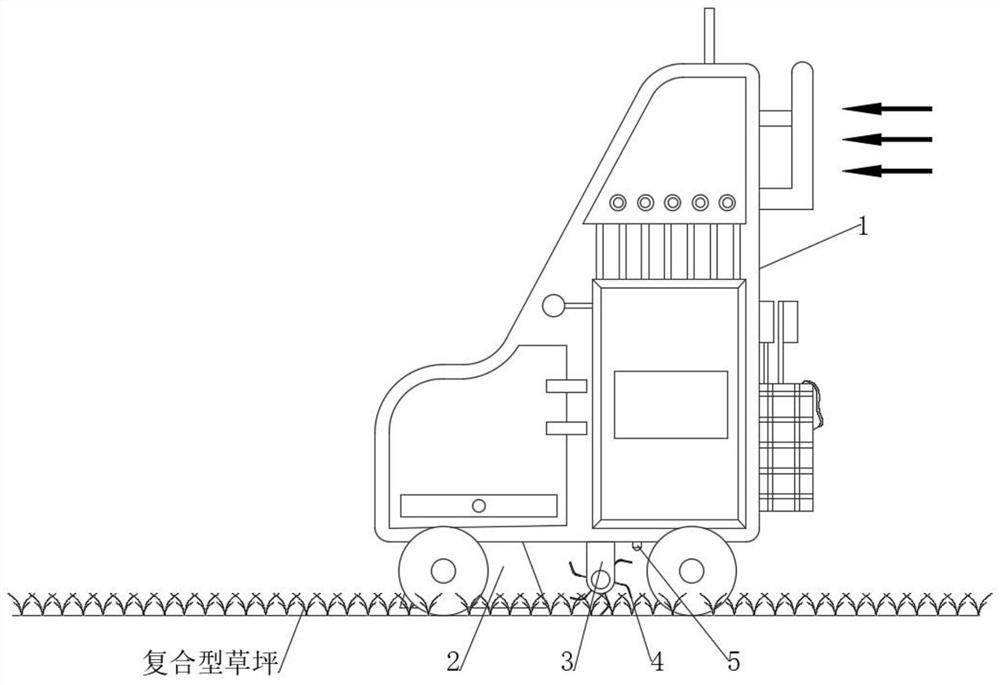

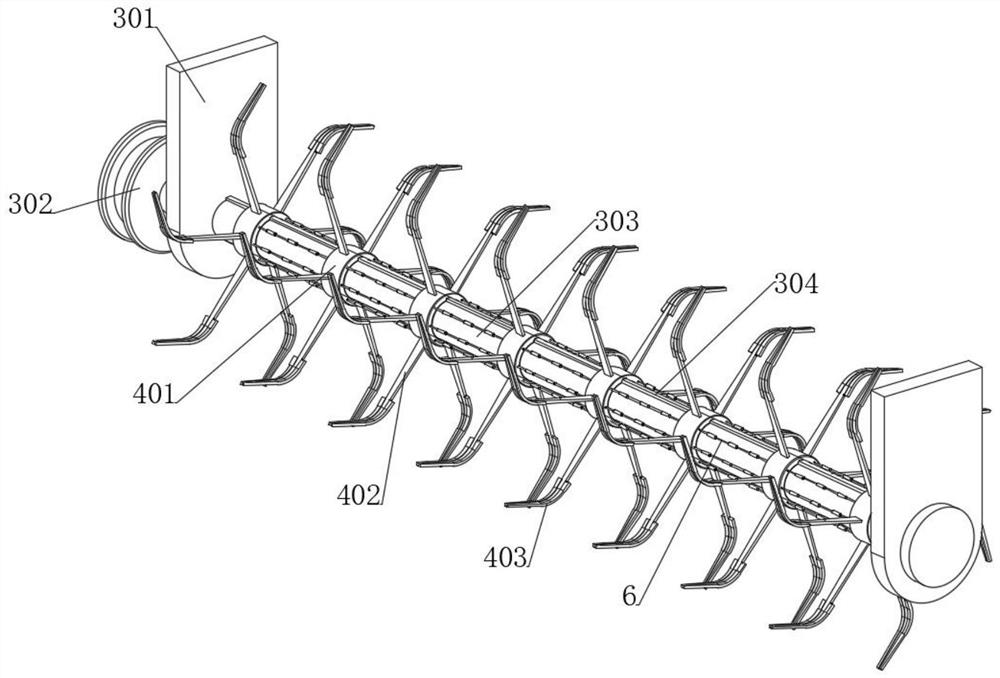

[0057] See Figure 1-8 The same or corresponding components as in Example 1 employ reference numerals corresponding to Embodiment 1, which is simply, and the difference points from Example 1 are described below. This Example 2 differs from the first embodiment in that: see figure 2 , image 3 with Figure 5 , Including turf maintenance vehicle body 1 pushing, pushing lawn maintenance vehicle body 1 is attached to the left end of the cleaner 2 impurity lawn, turf maintenance vehicle body 1 is driven with a rotary brush mounted lower comb assembly 2 located to the right of the cleaner impurity turf 3, rotary brush 4, the comb-type regulating wheel assembly is connected to the comb-type adjustment wheel assembly 3 comprises a carding gap 4 comb assembly rim 401, a plurality of rotary brush connecting gaps 401 3 carding combs rim assembly, the rim 401 the outer end of the comb gap a plurality of comb teeth fixedly connected circumferentially distributed 402, a gap between two adjacent co...

Embodiment 3

[0062] See Figure 1-8 The same or corresponding components as in Example 1 employ reference numerals corresponding to Embodiment 1, which is simply, and the difference points from Example 1 are described below. This Example 3 differs from the first embodiment in that: see Figure 4 with Image 6, Both end and rear end and rear end and rear end and rear end and rear end and rear, the inner end of the thermoplastic scuten tooth 403 is fixed to the side of the casing 403, and the corner 4031 and the combing wheel 402 rotate Connect, the combing wheel 402 is connected to the shaped gap assembly 7 that cooperates with the thermoplastic sputum 403.

[0063] See Figure 7 The shaping gap assembly 7 includes a shaped electric heating rod 701, and the combing wheel 402 is fixedly connected to the shaped electric heating rod 701, and the shaping electric heating rod 701 is fixed to and the thermal expansion strip 702, the thermal expansion strip 702 is filled There is a thermal sensitive gas t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com