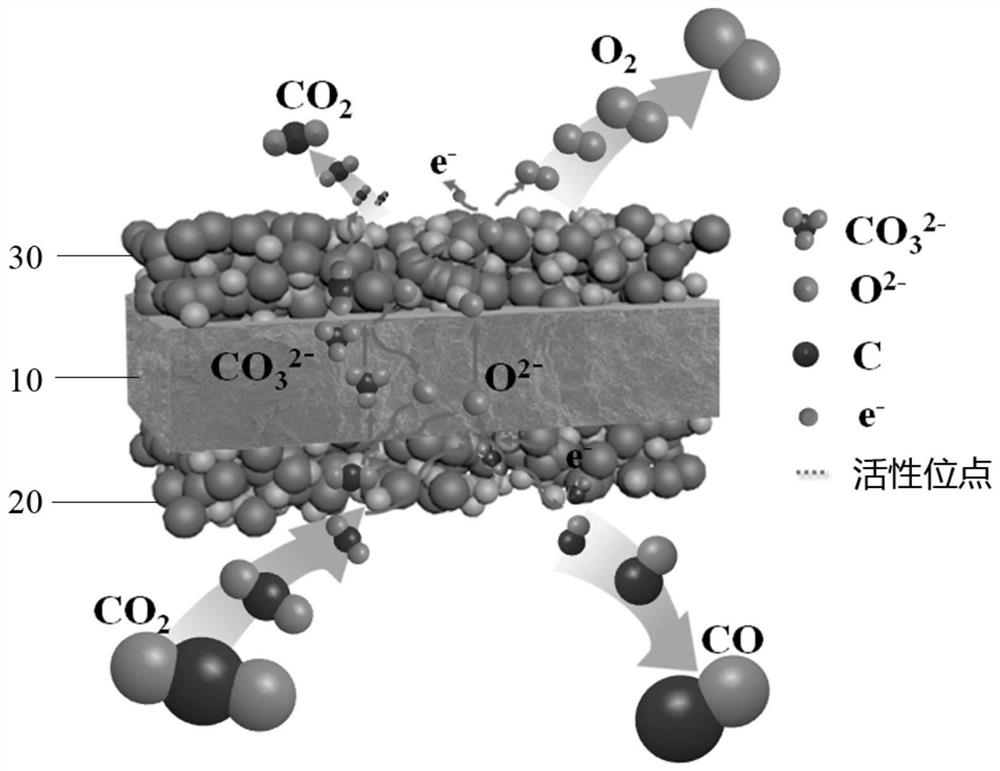

A carbon dioxide conversion electrolytic cell and its preparation method and application

A carbon dioxide, electrolytic cell technology, applied in electrolytic components, electrolytic process, electrolytic organic production, etc., can solve the problems of poor electrochemical performance, limited operating temperature of carbon dioxide conversion electrolytic cells, etc., to improve the conductivity and expand the electrolysis temperature range. , improve the effect of conversion kinetics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

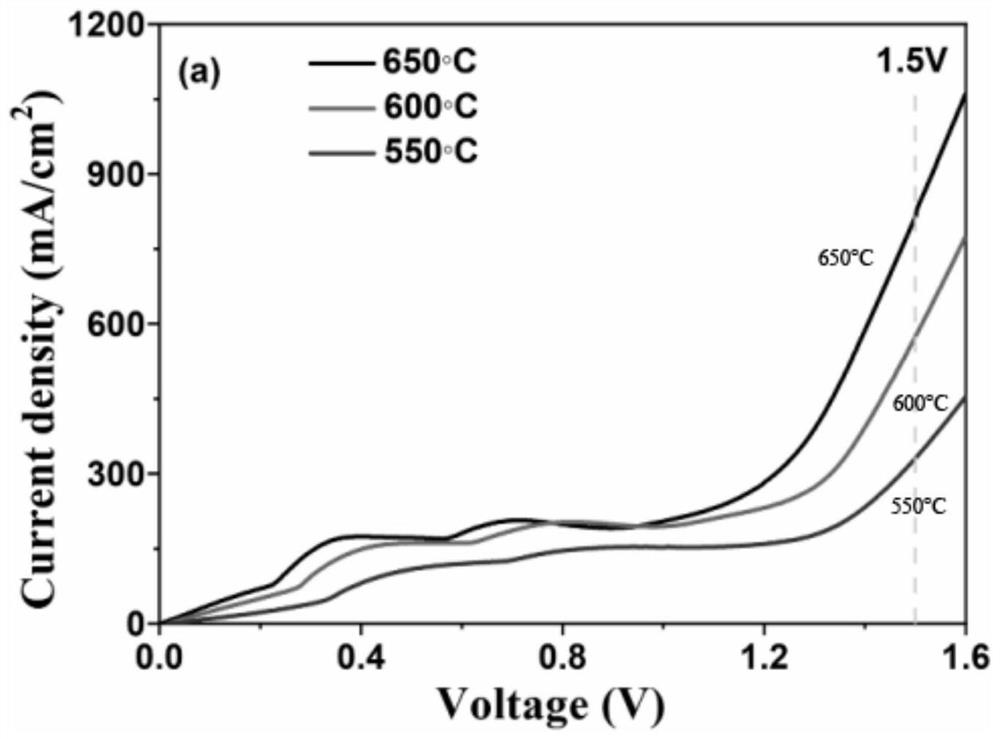

[0077] Follow the steps below to prepare an electrolytic cell for high-efficiency conversion of carbon dioxide at medium and low temperatures:

[0078] 1. Preparation of doped cerium oxide / carbonate electrolyte: weigh Ce(NO 3 ) 3 ·6H 2 O and Sm(NO 3 ) 3 ·6H 2 O in a 1000mL beaker, add an appropriate amount of deionized water and stir to dissolve to form a light yellow nitrate solution. 1mol / L NH 4 HCO 3 Pour the solution into the nitrate solution, and a large amount of white precipitates can be observed. Adjust the pH to 7-8, stir for 2 hours to fully precipitate the cations, and let stand overnight. Suction filtration was performed with a Buchner funnel, washed three times with deionized water and twice with absolute ethanol, and the filter residue was taken out and placed in a blast drying oven at 120°C for drying. The dried SDC precursor powder was placed in a high-temperature muffle furnace and calcined at 500-700° C. for 2 hours to obtain light yellow SDC powder. ...

Embodiment 2

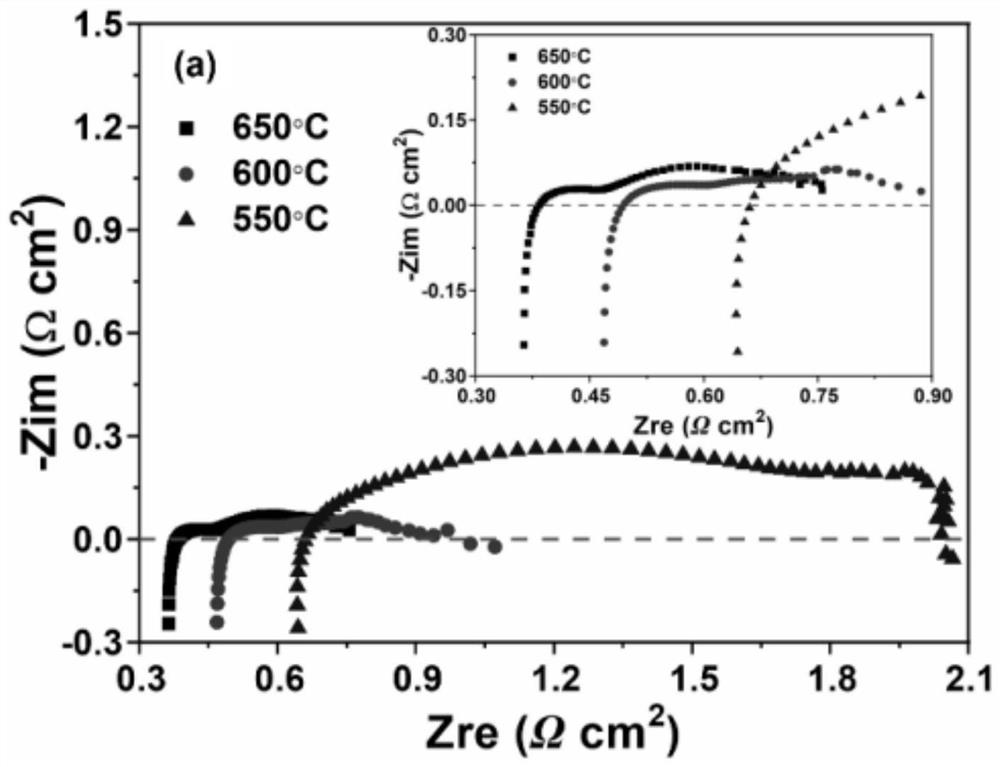

[0084] To evaluate electrolytic cells at low CO 2 Electrolyzed CO at concentration 2 The electrolytic performance performance, to the electrolytic cell that embodiment 1 makes under 1.6V, 600 ℃ condition, pass into 80%, 60%, 40% and 20% CO respectively at the cathode 2 / N 2 , to test different CO 2 Concentration of current density. At the same time, different CO 2 Electrochemical Impedance Spectroscopy of SOEC at Concentrations.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com