A method of manufacturing low-alloy ultra-high-strength steel

A technology of ultra-high-strength steel and low-alloy, which is applied in the field of preparation of low-alloy ultra-high-strength steel. Purity, the effect of optimizing the smelting process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

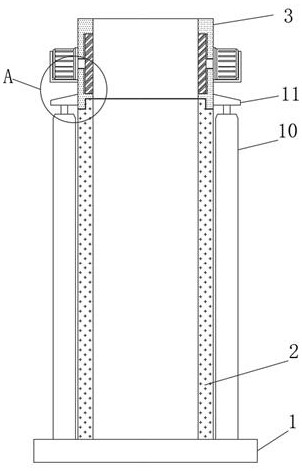

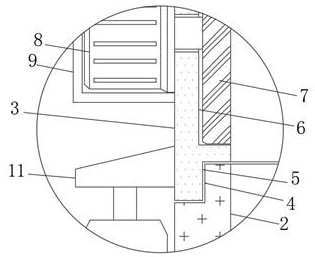

Image

Examples

Embodiment 1

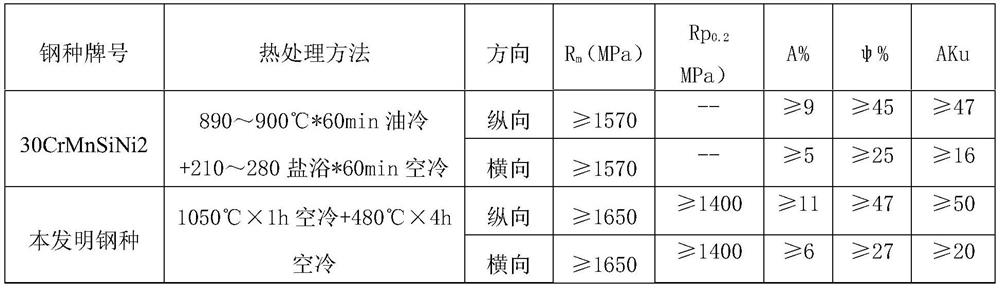

[0027] The invention provides a technical solution: a low-alloy ultra-high-strength steel. The formula of the low-alloy ultra-high-strength steel includes the following components: C: 0.30%, Mn: 1.0%, Si: 1.50%, S: 0.010% , P: 0.010%, Ni: 1.45%, Al: 0.03%, Cr: 0.80%, V: 0.08%, H: 0.0001%, O: 0.0015%, N: 0.010%, the balance is Fe and other unavoidable Impurities.

[0028] A method for manufacturing a low-alloy ultra-high-strength steel as described above, the preparation method includes the following steps:

[0029] S1: Quantitative weighing, all raw materials are weighed according to the above components;

[0030] S2: Smelting, using the smelting process of vacuum induction furnace smelting casting + vacuum self-consumption remelting to smelt raw materials into steel ingots;

[0031] S3: Forging, heat the consumable steel ingot to 1220°C and keep it warm for more than 25 hours, then diffuse to make the carbides dispersed and distributed, after diffusion, it is out of the fur...

Embodiment 2

[0037] The present invention provides a technical solution: a low-alloy ultra-high-strength steel, the formula of the low-alloy ultra-high-strength steel includes the following components: C: 0.35%, Mn: 1.5%, Si: 1.80%, S: 0.08% , P: 0.09%, Ni: 1.85%, Al: 0.08%, Cr: 1.20%, V: 0.15, H: 0.00008%, O: 0.0014%, N: 0.009%, the balance is Fe and other unavoidable impurities .

[0038] A method for manufacturing a low-alloy ultra-high-strength steel as described above, the preparation method includes the following steps:

[0039] S1: Quantitative weighing, all raw materials are weighed according to the above components;

[0040] S2: Smelting, using the smelting process of vacuum induction furnace smelting casting + vacuum self-consumption remelting to smelt raw materials into steel ingots;

[0041] S3: Forging, heat the consumable steel ingot to 1220°C and keep it warm for more than 25 hours, diffuse and distribute the carbides, after diffusion, it is out of the furnace for forging,...

Embodiment 3

[0047] The invention provides a technical solution: a low-alloy ultra-high-strength steel. The formula of the low-alloy ultra-high-strength steel includes the following components: C: 0.32%, Mn: 1.2%, Si: 1.60%, S: 0.007% , P: 0.006%, Ni: 1.55%, Al: 0.05%, Cr: 0.90%, V: 0.10%, H: 0.00007%, O: 0.0013%, N: 0.007%, the balance is Fe and other unavoidable Impurities.

[0048] A method for manufacturing a low-alloy ultra-high-strength steel as described above, the preparation method includes the following steps:

[0049] S1: Quantitative weighing, all raw materials are weighed according to the above components;

[0050] S2: Smelting, using the smelting process of vacuum induction furnace smelting casting + vacuum self-consumption remelting to smelt raw materials into steel ingots;

[0051] S3: Forging, heat the consumable steel ingot to 1220°C and keep it warm for more than 25 hours, diffuse and distribute the carbides, and then take out the furnace for forging. In the best ther...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com