A low-carbon low-alloy steel pouring stopper rod and steelmaking process using the stopper rod

A technology of low-alloy steel and process, which is applied in the field of low-carbon low-alloy steel process and low-carbon low-alloy steel pouring stopper, which can solve the problems of stopper head erosion, uncontrollable flow, unsatisfactory deoxidation effect of molten steel, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0027] A stopper head used for pouring low-carbon and low-alloy steel and its application process provided by this invention are produced on a low-carbon and low-alloy steel production line in a steel factory, and the production process is as follows.

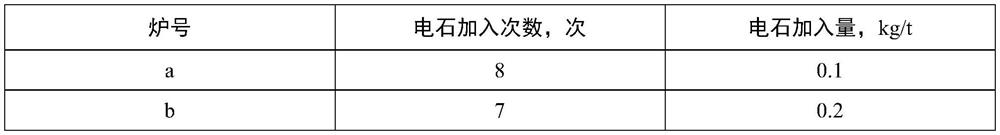

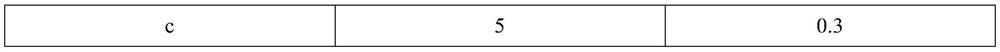

[0028](1) Add low-carbon ferrosilicon, low-carbon manganese, ferrochrome and carbon powder for deoxidation alloying when tapping the converter, and add lime, lightly burned magnesium balls, and synthetic slag to make slag at the same time, and add to the slag surface of the ladle after tapping Calcium carbide. The amount added is shown in Table 1 below. The composition of the synthetic slag is shown in Table 2. The bottom blowing control is shown in Table 3.

[0029] Table 1 Addition of raw and auxiliary materials for converter tapping

[0030] furnace number Lime, kg / t Lightly burned magnesium balls, kg / t Synthetic slag, kg / t Calcium carbide, kg / t a 5 0.5 2 1.0 b 4 1.1 1.4 0.3 c 3 1.5 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com