Foamed ceramic prepared from gold tailings and coal gangue and preparation method

A technology of foamed ceramics and coal gangue, which is applied in the field of building materials, can solve the problems of low utilization of gold tailings and coal gangue, complex preparation processes, etc., and achieve the effects of improving physical and chemical properties, simple process, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

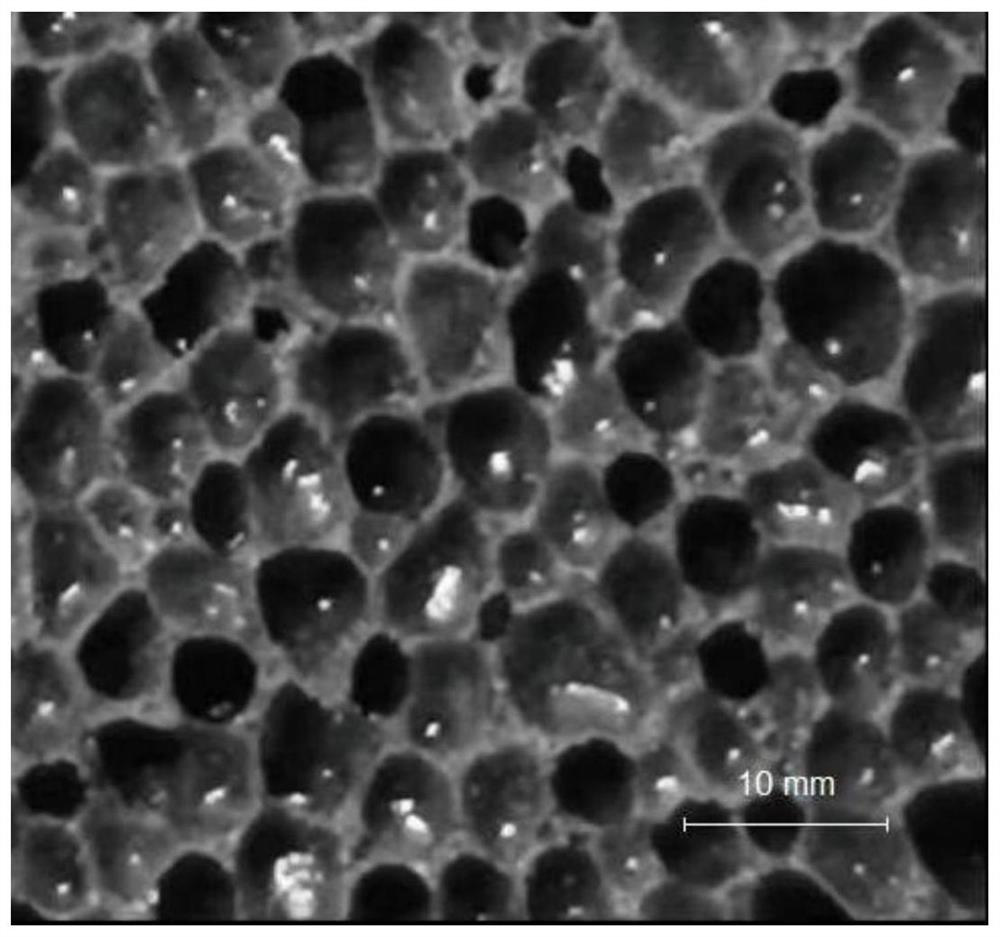

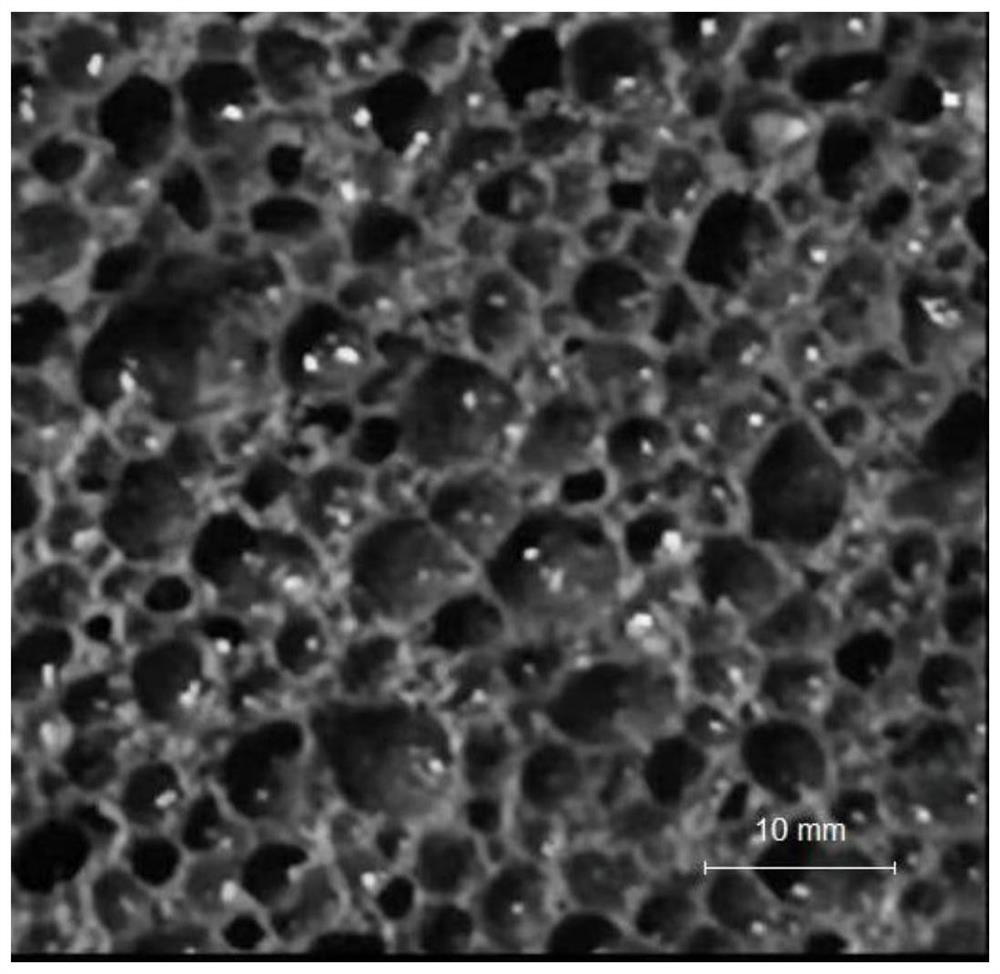

Image

Examples

preparation example Construction

[0032] The present invention also provides a method for preparing foamed ceramics prepared from gold tailings and coal gangue, comprising the following steps:

[0033] (1) After weighing gold tailings, microsilica fume, coal gangue, albite, silicon carbide micropowder, talc, and calcite in proportion, carry out ball milling and mix;

[0034] (2) Put the mixed powder into the mould, pave and compact it to obtain a green body;

[0035] (3) After the green body is preheated, foamed, stabilized, and annealed, foamed ceramics are obtained.

[0036] Preferably, the preheating stage of step (3) is: put the green body into a high-temperature furnace, raise the temperature from room temperature to 400-600°C at a heating rate of 10-15°C / min, and keep it warm for 30-90min; The rate is 12-13°C / min, the temperature is raised to 480-520°C, and the holding time is 50-70min.

[0037] Preferably, the foaming stage of step (3) is: after the preheating is completed, the temperature is raised t...

Embodiment 1

[0045] The present embodiment utilizes the preparation method of the foamed ceramics prepared by gold tailings and coal gangue, comprising the following steps:

[0046] (1) Take by weight 45 parts of gold tailings, 25 parts of coal gangue, 2 parts of microsilica fume, 4.8 parts of albite, 0.2 part of silicon carbide micropowder, 2 parts of talc, and 2 parts of calcite, mix and put Put into ball mill for 0.5h, pass through 180 mesh sieve after ball milling;

[0047] (2) Putting the mixed powder into the mold to pave and compact to obtain a green body, wherein the green body accounts for 40% of the mold volume;

[0048] (3) Put the green body into the high-temperature furnace for preheating, and raise the temperature from room temperature to 400°C at a heating rate of 10°C / min, and keep it warm for 30 minutes; after the preheating is completed, raise the temperature to 1150°C at a heating rate of 2°C / min , keep warm for 30 minutes, and start foaming; after the foaming is complete...

Embodiment 2

[0050] The present embodiment utilizes the preparation method of the foamed ceramics prepared by gold tailings and coal gangue, comprising the following steps:

[0051] (1) Take by weight 52 parts of gold tailings, 30 parts of coal gangue, 5 parts of microsilica fume, 6 parts of albite feldspar, 0.3 part of silicon carbide micropowder, 3 parts of talc, 4 parts of calcite, mix, put Enter the ball mill for 1 hour, and pass through a 200-mesh sieve after ball milling;

[0052] (2) put the mixed powder into the mold to pave and compact to obtain a green body, wherein the green body accounts for 46% of the mold volume;

[0053] (3) Put the green body into a high-temperature furnace for preheating, and raise the temperature from room temperature to 520°C at a heating rate of 12°C / min, and keep it for 60 minutes; after the preheating is completed, raise the temperature to 1170°C at a heating rate of 3°C / min , keep warm for 60 minutes, and start foaming; after the foaming is complete...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com