High-performance core material, preparation method and application of high-performance core material in preparation of polyphenyl granule light partition board

A technology of lightweight partition board and polystyrene particles, which is applied in the field of building materials, can solve the problems of low compressive strength and failure to meet the use requirements, and achieve good compressive strength, meet the needs of popularization and application, and strong hanging force Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

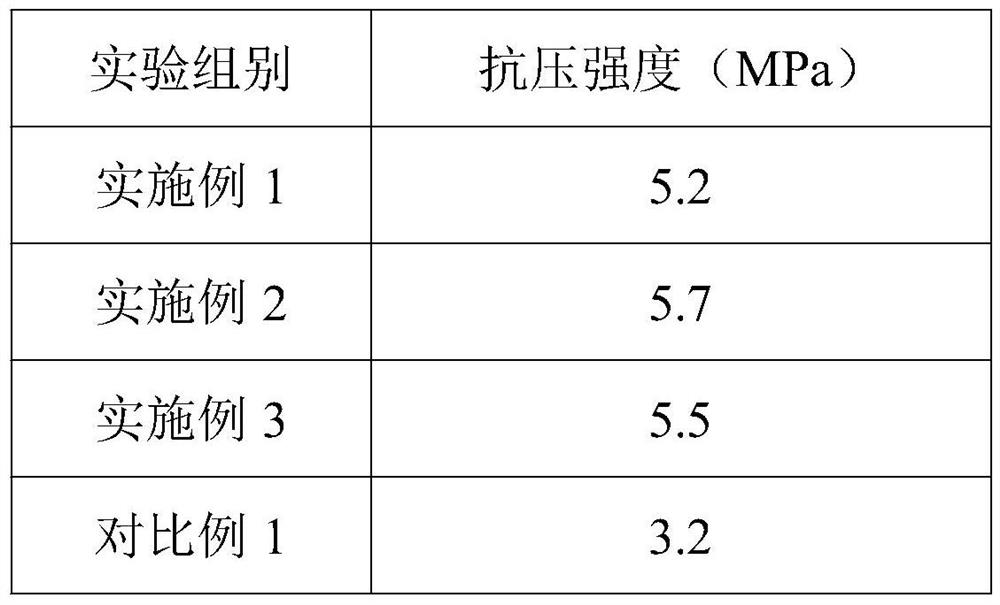

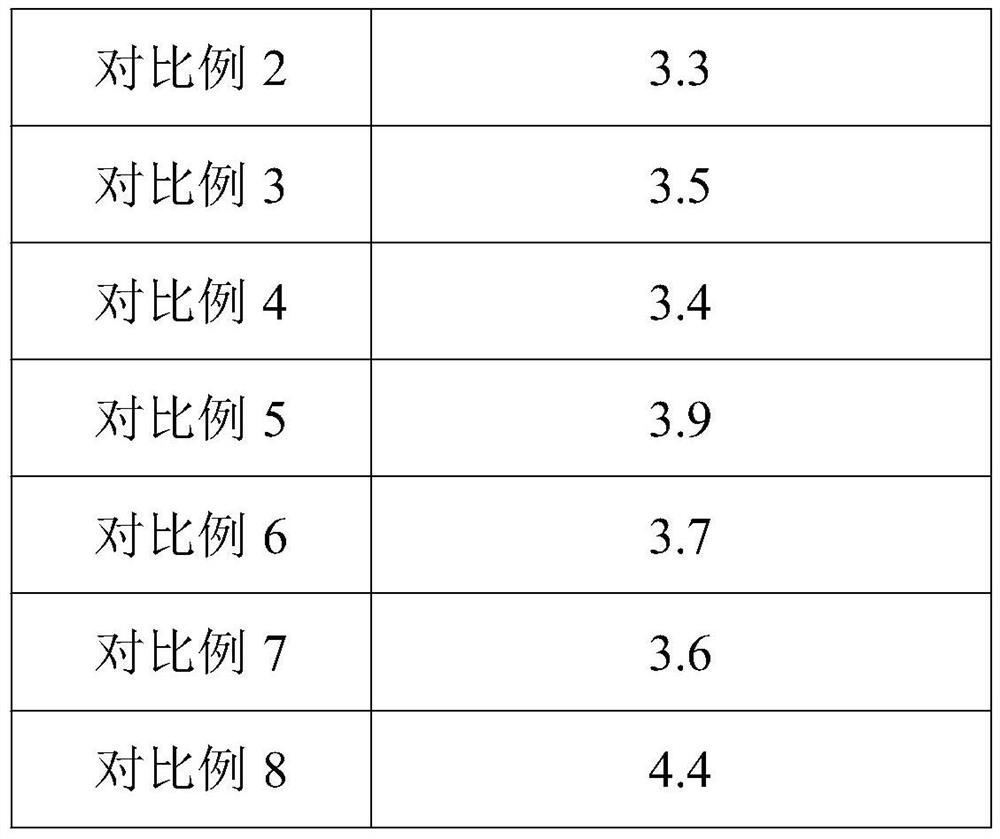

Examples

preparation example Construction

[0032] The preparation method of the high-performance core material comprises the following steps:

[0033] (1) stirring the cement, fly ash and water in parts by weight for 12-18min at a rotating speed of 300-500r / min to obtain a slurry;

[0034] (2) polystyrene particles, sand, resorcinol, maleic anhydride, zeolite powder, ethylene phosphate, foaming agent, foam stabilizer, hydrogen peroxide in the temperature of 62-67 ℃, rotating speed is 300 Stir at -400r / min for 1-1.3h to obtain a foam solution;

[0035] (3) The slurry prepared in step (1), the foam liquid prepared in step (2) and tert-butyl peroxy tert-valerate, trimethylolpropane tris (3- aziridinyl propionate) ), acetylacetone, 1,2-cyclohexanediamine, 2,2-bis(tert-butylperoxy)butane, and starch octenyl succinate are mixed at a temperature of 67-72°C and a speed of 300- Stir at 400r / min for 1.7-2.4h to obtain a high-performance core material.

Embodiment 1

[0038] A high-performance core material includes the following raw materials in parts by weight: 95 parts of cement, 10 parts of fly ash, 42 parts of polystyrene particles, 2-5 parts of sand, 8 parts of resorcinol, and 6 parts of maleic anhydride Parts, 9 parts of zeolite powder, 4 parts of vinyl phosphate, 0.7 parts of foaming agent, 0.3 parts of foam stabilizer, 16 parts of hydrogen peroxide, 3.8 parts of Aziridinyl propionate) 0.9 parts, acetylacetone 1.3 parts, 1,2-cyclohexanediamine 5 parts, 2,2-bis(tert-butyl peroxy)butane 1.7 parts, octenyl succinic acid starch 7.8 parts of ester, 520 parts of water;

[0039] Described cement is portland cement;

[0040] Described whipping agent is azodicarbonamide;

[0041] Described foam stabilizer is lauryl dimethyl amine oxide;

[0042] The mass concentration of the hydrogen peroxide is 29%;

[0043] The preparation method of the high-performance core material comprises the following steps:

[0044] (1) Stir the cement, fly ash...

Embodiment 2

[0048] A high-performance core material includes the following raw materials in parts by weight: 116 parts of cement, 12 parts of fly ash, 48 parts of polystyrene particles, 4 parts of sand, 10 parts of resorcinol, 9 parts of maleic anhydride, 11 parts of zeolite powder, 7 parts of ethylene phosphate, 0.8 parts of foaming agent, 0.5 parts of foam stabilizer, 17 parts of hydrogen peroxide, 5.3 parts of tert-butyl peroxy tert-valerate, 5.3 parts of trimethylolpropane tris(3-ethyleneimine) 1.2 parts of pyridyl propionate), 1.6 parts of acetylacetone, 6.2 parts of 1,2-cyclohexanediamine, 1.8 parts of 2,2-di(tert-butyl peroxy)butane, 8.2 parts of octenyl succinic acid starch ester parts, 600 parts of water;

[0049] Described cement is portland cement;

[0050] Described whipping agent is azodicarbonamide;

[0051] Described foam stabilizer is lauryl dimethyl amine oxide;

[0052] The mass concentration of the hydrogen peroxide is 31%;

[0053] The preparation method of the hig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com