Preparation method of natural photosensitizer hypocrellin nano bactericidal emulsion

A technology of hypocrellin and nano-sterilization, applied in food ingredients as emulsifiers, food ingredients as antimicrobial preservation, food science, etc., can solve the problems of poor water solubility of photosensitizers, limit the application of photosensitizers, poor stability, etc. Achieve the effects of reducing production costs, expanding the scope of application, and improving solubility and usability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

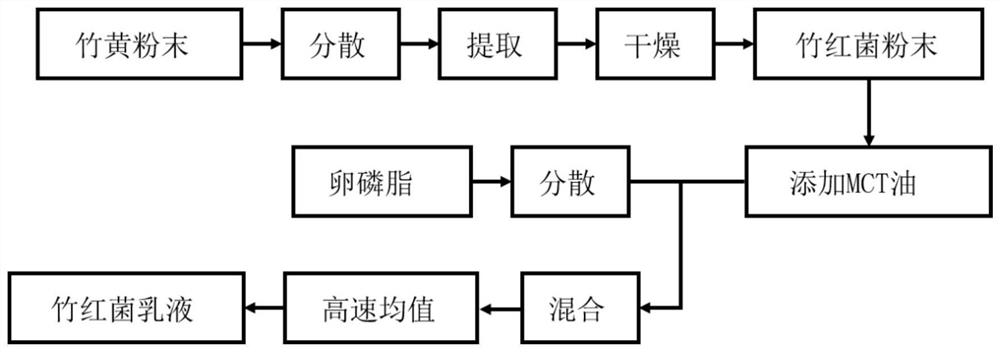

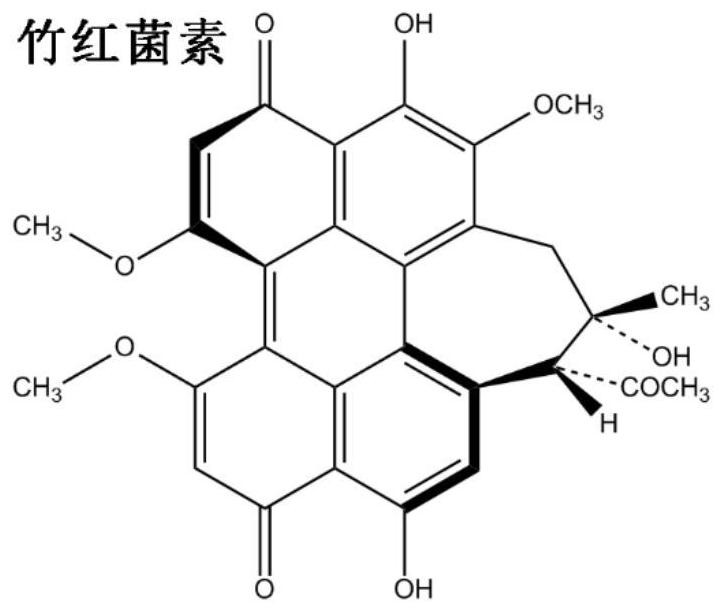

[0028] Preparation of photosensitizer: take bamboo yellow as raw material, grind it into powder, take 160g and place it in a Soxhlet extractor, add 500mL of acetone, heat with 75mL, carry out heat reflux, and circulate for 10h; Rotary steam for 30min to recover acetone; put in a beaker, add 200mL petroleum ether, heat with 80mL, stir while heating until boiling, carry out 30min, after cooling, use Buchner funnel suction filtration, repeat 3 times, get the initial product; Add 100mL of toluene and petroleum ether to the beaker of the initial product, recrystallize in 50mL for 30min, and dry in 70mL for 24h to obtain hypocrellin.

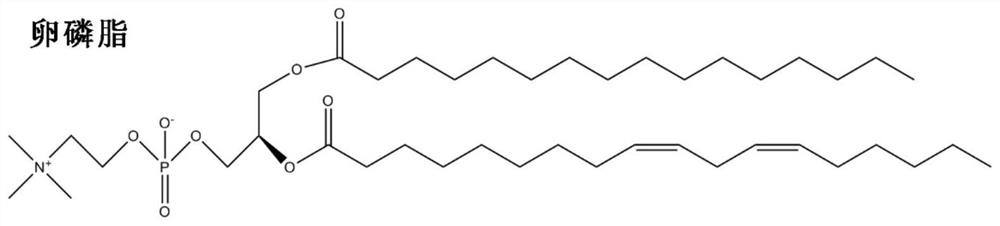

[0029] Preparation of primary emulsion: take 0.1g hypocrellin powder, add medium-chain triglycerides to 10g, take 1.8g lecithin, add deionized water to 90g; mix the oil phase and water phase, at 300r / min speed, temperature 10min at 55mL.

[0030] Preparation of nanoemulsion: The primary emulsion was sheared at a speed of 1300r / min for 25 minutes in a...

Embodiment 2

[0032] Preparation of photosensitizer: take bamboo yellow as raw material, grind it into powder, take 160g and place it in a Soxhlet extractor, add 500mL of acetone, heat with 85mL, carry out heat reflux, and circulate for 10h; Rotary steam for 30min to recover acetone; put in a beaker, add 200mL petroleum ether, heat with 80mL, stir while heating until boiling, carry out 30min, after cooling, use Buchner funnel suction filtration, repeat 3 times, get the initial product; Add 100mL of toluene and petroleum ether to the beaker of the initial product, recrystallize in 50mL for 30min, and dry in 70mL for 24h to obtain hypocrellin.

[0033] Preparation of primary emulsion: take 0.1g hypocrellin powder, add medium-chain triglycerides to 10g, take 1.8g lecithin, add deionized water to 90g; mix the oil phase and water phase, at 300r / min speed, temperature 10min at 55mL.

[0034] Preparation of nanoemulsion: The primary emulsion was sheared at a speed of 1300r / min for 25 minutes in a...

Embodiment 3

[0036]Preparation of photosensitizer: take bamboo yellow as raw material, grind it into powder, take 160g and place it in a Soxhlet extractor, add 500mL of acetone, heat with 85mL, carry out heat reflux, and circulate for 10h; Rotary steam for 30min to recover acetone; put in a beaker, add 200mL petroleum ether, heat with 80mL, stir while heating until boiling, carry out 30min, after cooling, use Buchner funnel suction filtration, repeat 3 times, get the initial product; Add 100mL of toluene and petroleum ether to the beaker of the initial product, recrystallize in 50mL for 30min, and dry in 70mL for 24h to obtain hypocrellin.

[0037] Preparation of primary emulsion: take 0.2g hypocrellin powder, add medium chain triglycerides to 10g, take 1.8g lecithin, add deionized water to 90g; mix the oil phase and water phase, at 300r / min speed, temperature 10min at 55°C.

[0038] Preparation of nanoemulsion: The primary emulsion was sheared at a speed of 1300r / min for 25 minutes in a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com