Finite element method-based composite insulation state evaluation method considering sleeve oil-paper insulation non-uniform thermal aging effect

An oil-paper insulation and composite insulation technology, applied in design optimization/simulation, special data processing applications, instruments, etc., can solve problems such as uneven aging of casing oil-paper, and achieve the effect of overcoming experimental errors and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0043] A composite insulation state evaluation method considering the uneven thermal aging effect of casing oil-paper insulation based on the finite element method, including the following steps:

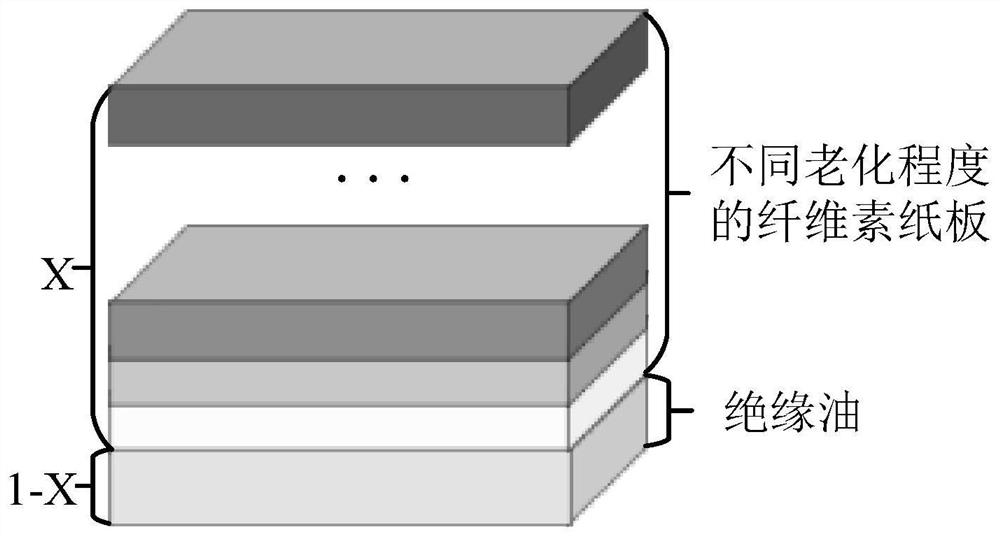

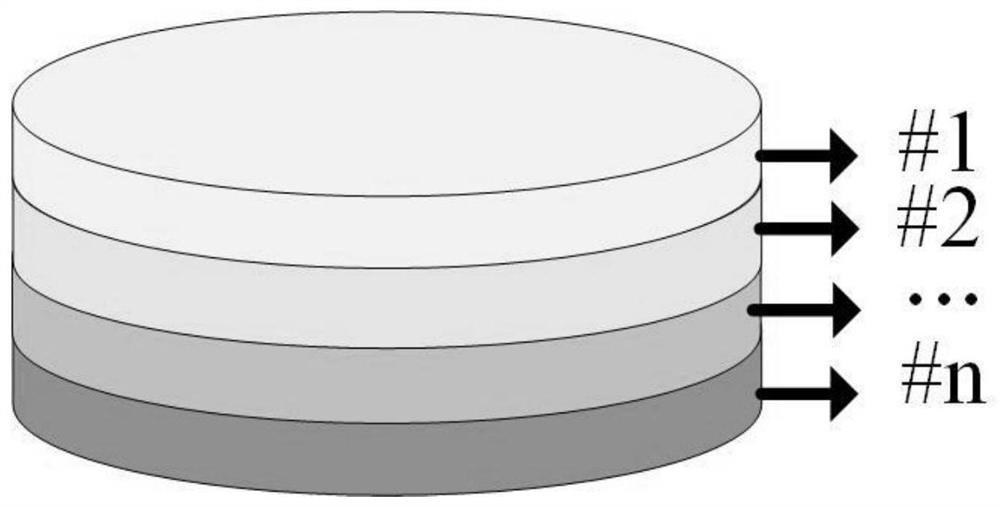

[0044] (1) Considering the influence of radial uneven thermal aging in the casing, an equivalent physical composite model is constructed on the basis of the traditional X model, such as figure 1 Shown; X is the ratio of the total thickness of insulating paperboard to oil-paper insulation, and 1-X is the ratio of the total thickness of insulating oil to oil-paper insulation. Since the oil content in the casing oil-paper insulation system is very small, X and 1-X 95% and 5% respectively;

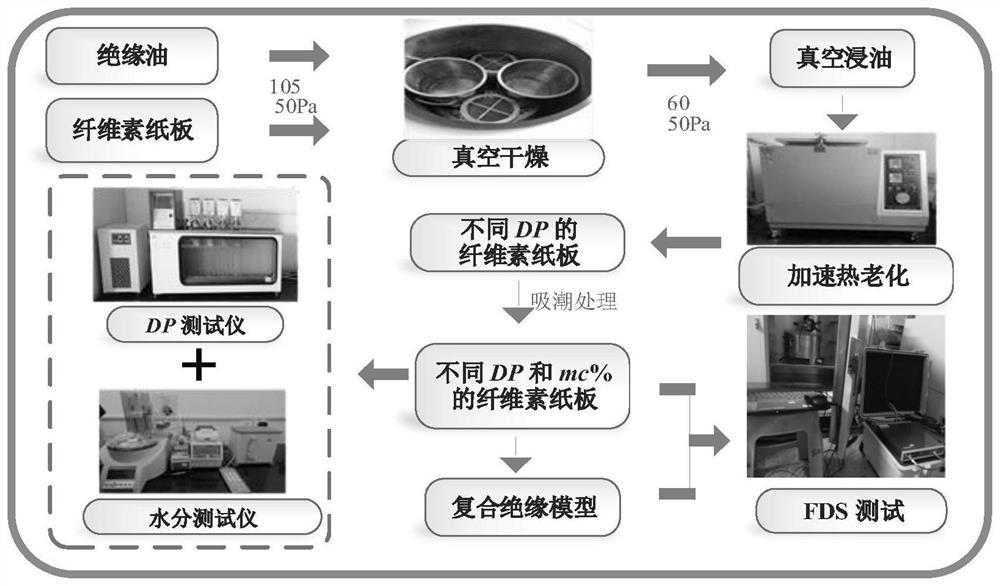

[0045] (2) Dry the insulating cardboard and insulating oil in a vacuum drying oven with a temperature of 105°C and a vacuum of 50Pa for 48 hours, and then immerse the insulating cardboard in an environment with a temperature of 60°C and a vacuum of 50Pa for 48 hours to obtain a pretreated insulating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com