Strip steel cleaning method capable of reducing alkali liquor consumption

A technology of lye and strip steel, which is applied in the field of iron and steel metallurgy, can solve the problems of high process cost, discharge of hazardous lye chemicals, and high lye consumption, so as to reduce lye consumption and increase economic and social benefits , the effect of reducing the consumption of lye

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

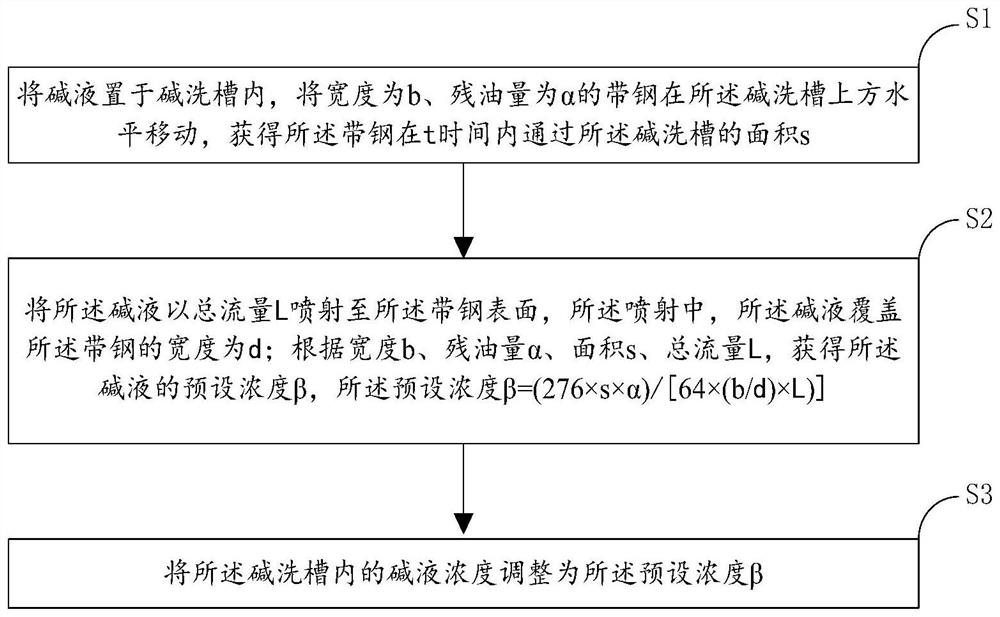

Method used

Image

Examples

Embodiment 1

[0052] A kind of strip cleaning method that the present embodiment provides to reduce the consumption of lye is illustrated by taking the 1850 steel strip of a certain domestic cold rolling factory as an example.

[0053] (1) Most domestic steel mills will conservatively choose high-concentration lye to ensure cleaning quality, but the lye concentration has remained unchanged, basically fixed at about 35g / L, and has not been adjusted according to the cleanliness of incoming materials , which leads to an excess of lye.

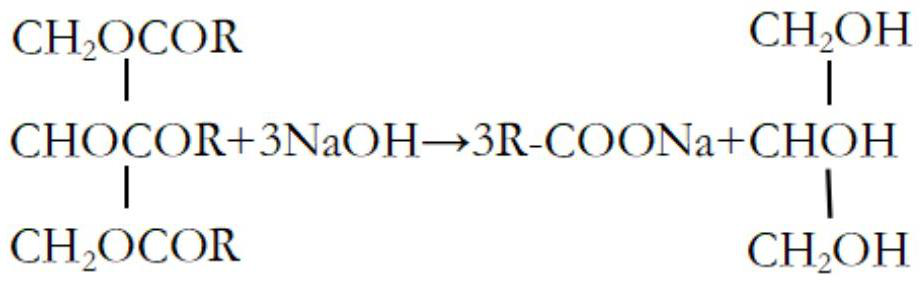

[0054] (2) Saponification reaction principle: According to actual inspection, the composition of residual oil in chilled rolls is mainly composed of two parts, palm fat and fatty acid, the ratio of the two is about 4:1, and the equations of its reaction with lye are respectively:

[0055] A, the reaction equation of palm fat and lye is:

[0056]

[0057] B, the reaction equation of fatty acid and lye is:

[0058] RCOOH+NaOH→RCOONa+H 2 o

[0059] It can b...

Embodiment 2

[0069] A kind of strip cleaning method that the present embodiment provides to reduce the consumption of lye is illustrated by taking the 1850 steel strip of a certain domestic cold rolling factory as an example.

[0070] In the present embodiment, the area s of the strip passing through the lye tank in 60min is 36000m 2 , strip width b = 1500mm, f 1 and f 2 3360L and 3000L respectively; the number of nozzles is A 1 and A 2 16 and 150 respectively;

[0071] The amount of residual oil on the surface of the strip α = 250mg / m 2 ;

[0072] Assuming that the concentration of lye in the alkaline washing tank is β at this time, then within time t:

[0073] 276×s×α=164×β×(b / 2100)×(f1×A1+f1×A2)

[0074] Can calculate the lye concentration β=42mg / L in the soda washing tank at this moment thus. The lye concentration at this time follows the dynamic change of the residual oil on the surface of the steel strip passing through the cleaning section. For the convenience of operation, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com